A Construction Technology of Reserved Central Rock Pillar in Super-long-span Dome of Underground Nuclear Reactor Cavern

A technology for nuclear reactor and construction technology, applied in underground chambers, mining equipment, earth-moving drilling, etc., can solve problems such as improper construction technology, safety accidents, and quality control, and achieve convenient construction, improve safety, and reduce surrounding rock. Effects of Stress Levels and Deformation Levels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

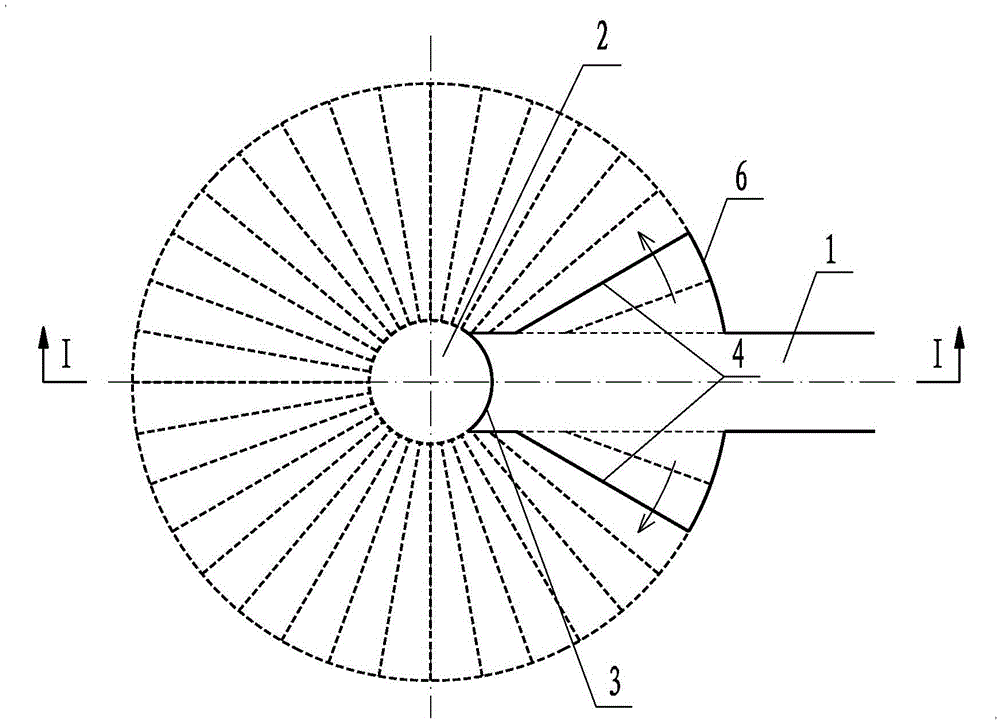

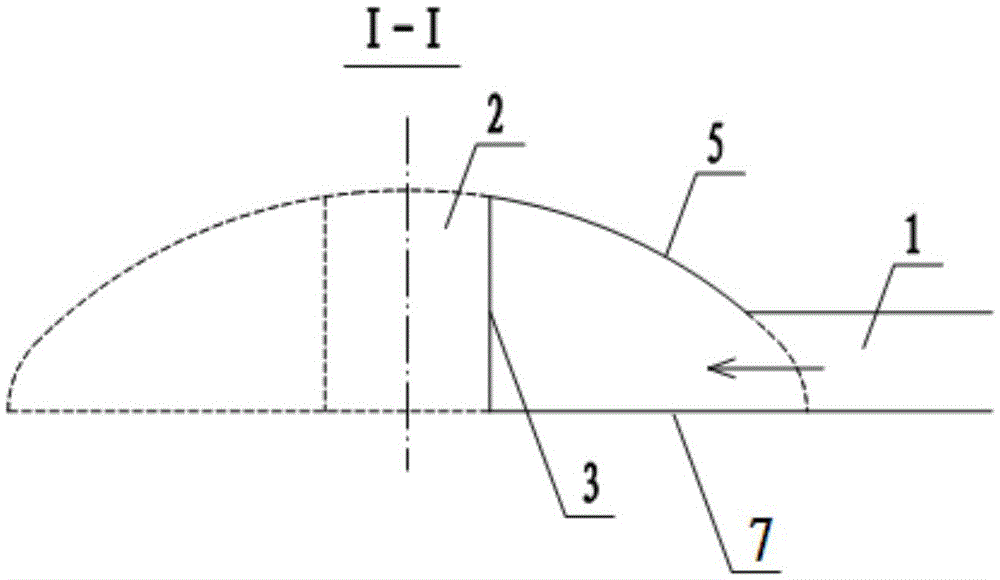

[0027] The super-long-span dome of the underground nuclear reactor cavern has an excavation diameter of 48m and a height of 13.4m. The excavation process of the reserved central rock pillar is as follows: reserve the central rock pillar 2 in the center of the dome, first open up the construction channel 1 with a radius to the central pillar, then expand the left and right sides symmetrically in a fan shape, and finally start from the top. And excavate central rock pillar 2 down.

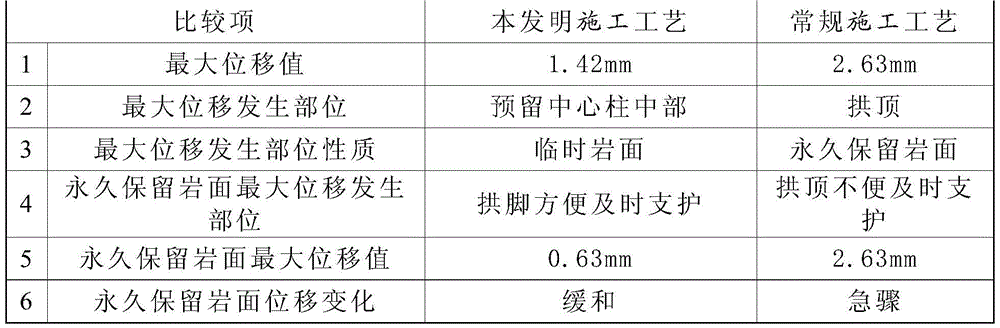

[0028] The reserved central rock pillar 2 of the dome is a circle with better stress conditions, and the cross-section is 12m in diameter. By establishing a three-dimensional numerical model to simulate the excavation process of the reserved central rock pillar method, and setting monitoring points on the exposed rock surface for tracking and monitoring, the results show that the deformation of the surrounding rock during the step-by-step construction meets the safety requirements. After step-by-ste...

Embodiment 2

[0033] The large-span dome of the surge shaft of the hydropower station has an excavation diameter of 41m and a height of 10.0m. The excavation process of the reserved central rock pillar is as follows: reserve the central rock pillar 2 in the center of the dome, first open the construction channel 1 from the radius to the central pillar, then expand the left and right sides symmetrically in a fan shape, and finally start from the top. And excavate central rock pillar 2 down.

[0034] The cross-section of the central rock pillar 2 reserved in the dome is 8m in diameter, which is a circle with good stress conditions.

[0035] During the entire excavation process, the support and monitoring of key control key parts such as the middle part of the temporarily expanded excavation face 4, the middle part of the reserved central rock pillar 2, and the arch foot 6 of the dome contour are emphasized.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com