An ultrasonic liquid flow measurement device

A technology for liquid flow and measuring device, which is applied in the direction of measuring device, liquid/fluid solid measurement, measuring flow/mass flow, etc. It can solve the problems of measuring the difference in the inner wall smoothness of straight pipes, affecting the accuracy of liquid flow measurement, and affecting the accuracy of measuring instruments, etc. , to achieve the effect of changing the range, prolonging the service life and improving the measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

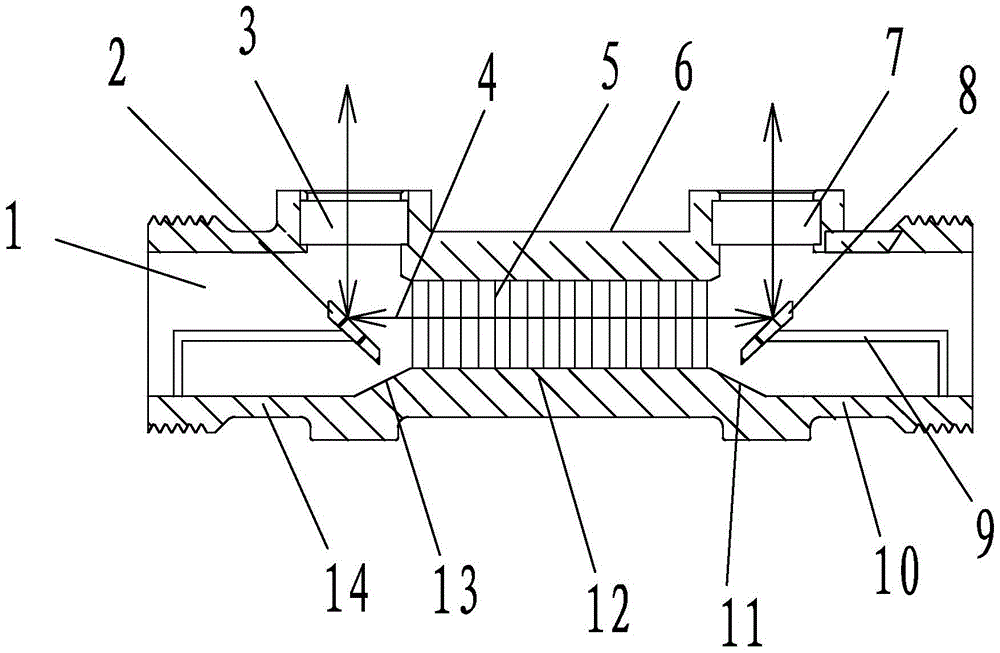

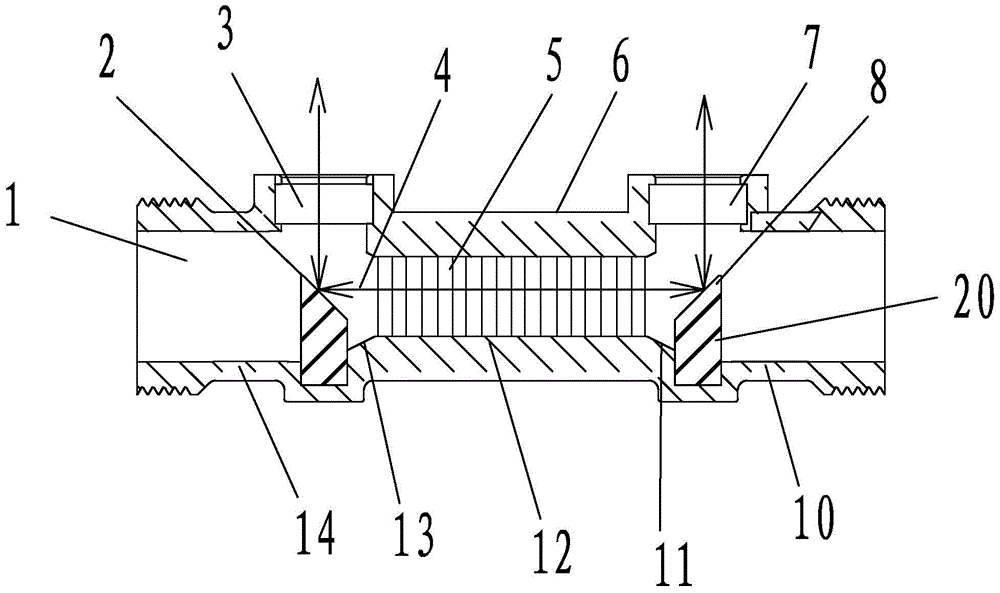

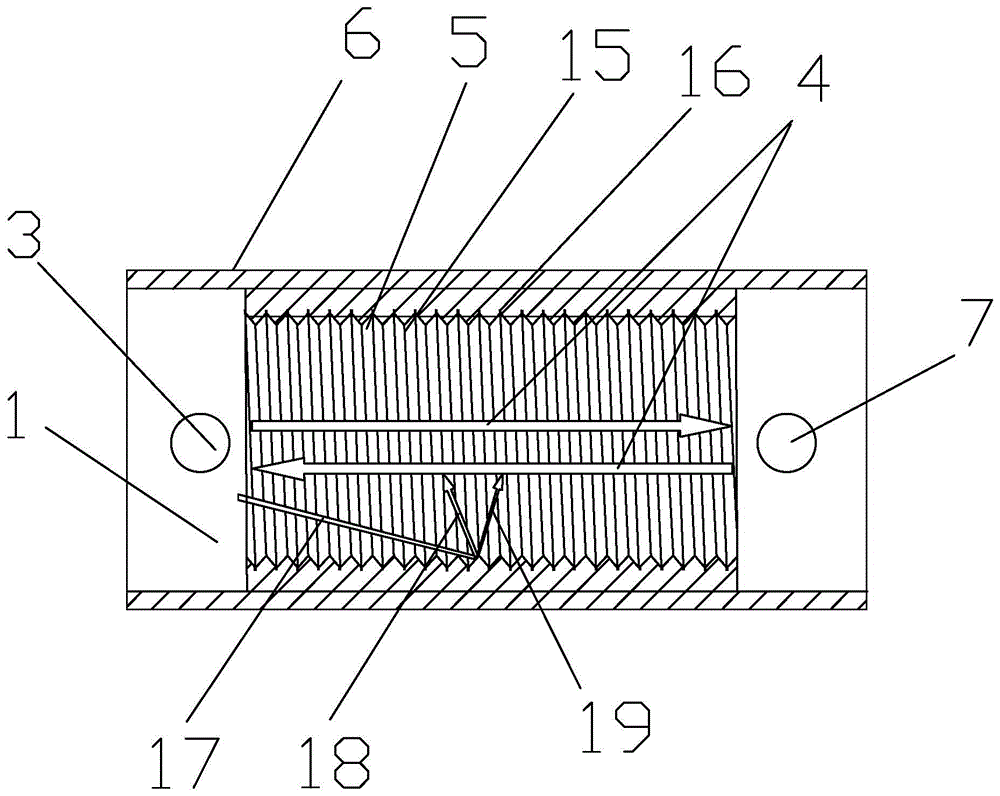

[0022] Example 1, a kind of ultrasonic liquid flow measuring device, such as figure 1 , image 3 As shown, it includes a measuring straight pipe 6 with a total length of 180 mm, and also includes a left ultrasonic transmitting receiver and a right ultrasonic transmitting receiver, and the measuring straight pipe is provided with a left hole and a right hole, and the center line of the left hole, the right The centerline of the hole and the centerline of the measuring straight pipe are in the same waveguide plane; a left reflection mechanism is fixed at the intersection of the centerline of the left hole and the centerline of the measuring straight pipe, and the left reflection mechanism is fixed on the Measure inside the straight pipe, and the reflection surface of the left reflection mechanism is perpendicular to the waveguide plane, the angle between the right end of the center line of the measurement straight pipe and the reflection surface of the left reflection mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com