Assembling and adjusting test bench for split type moving wheel pair hollow shaft sleeve

A hollow shaft sleeve and test bench technology, which is used in railway vehicle testing, machine gear/transmission mechanism testing, etc., can solve the problem that the hollow shaft sleeve lacks a test bench for adjustment, the quality of adjustment is difficult to guarantee, and the wheelset bearing cannot be controlled. It can achieve the effect of simple operation, low cost and high control accuracy due to problems such as the installation and adjustment accuracy of the bearing groove of the half window.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

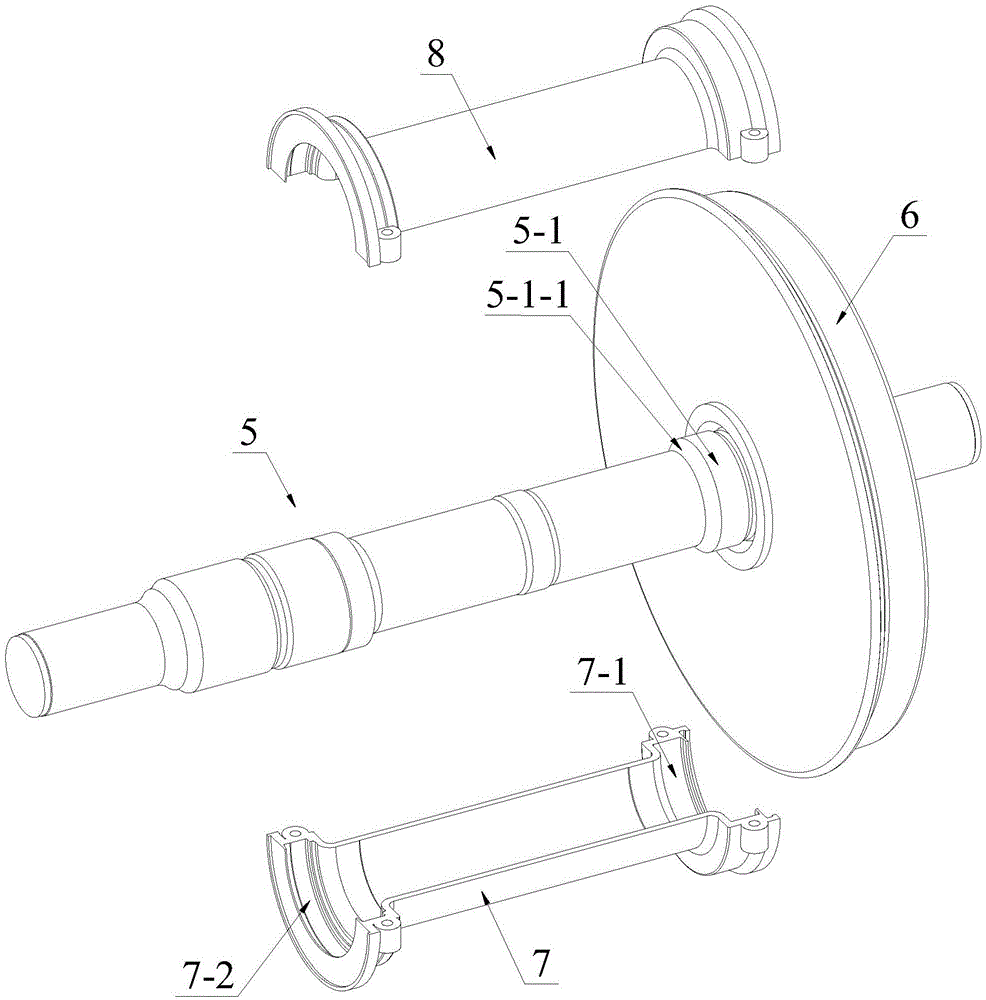

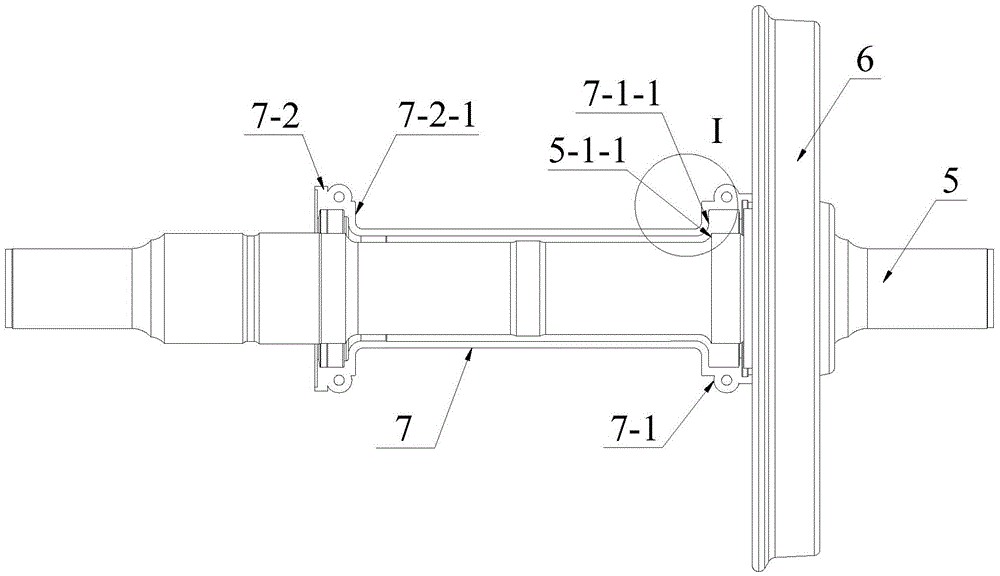

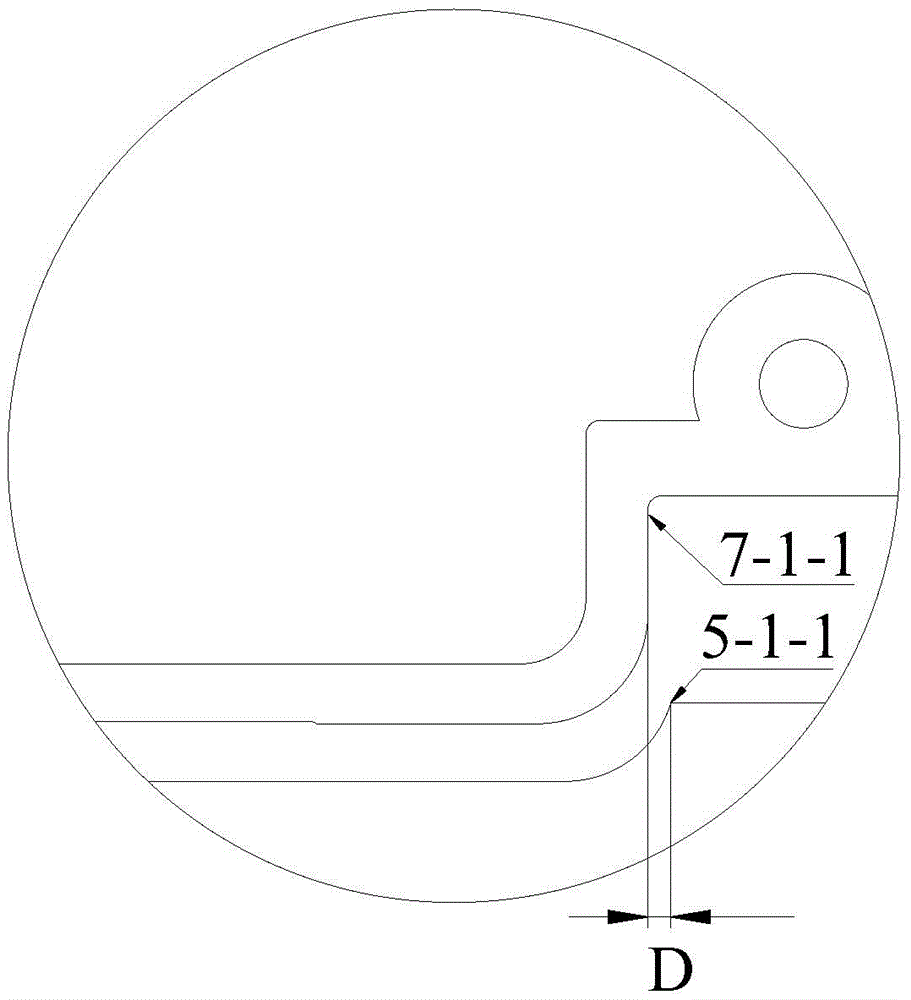

[0027] Such as Figure 4 to Figure 13 As shown, the present invention is used for the assembly and adjustment test bench of the split type moving wheel pair hollow shaft sleeve, including a platform 1, two V-shaped block assemblies 2, two small compression assemblies 3 and two large compression assemblies 4, The V-shaped block assembly 2 includes a V-shaped block 2-1 and two shock-absorbing anti-skid pads 2-2, the upper end surface of the V-shaped block 2-1 is provided with a V-shaped through groove, and two shock-absorbing anti-skid pads 2-2 It is symmetrically fixed on the inner wall of the V-shaped through groove. Two V-shaped block assemblies 2 are symmetrically fixed on both sides of the platform 1, and the two V-shaped through grooves of the two are aligned with each other along the slotting direction; the middle part of the platform 1 is provided with...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com