A loading device for a bearing testing machine

A loading device and bearing test technology, which is applied in the direction of mechanical bearing test, measuring device, impact test, etc., can solve the problems that the loaded load value cannot meet the requirements of the wheel bearing test, high test cost, poor safety, etc., and shorten the development cycle Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] This embodiment is a loading device used for a certain aircraft wheel bearing testing machine.

[0049] The loading device is a vertical hydraulic loading method.

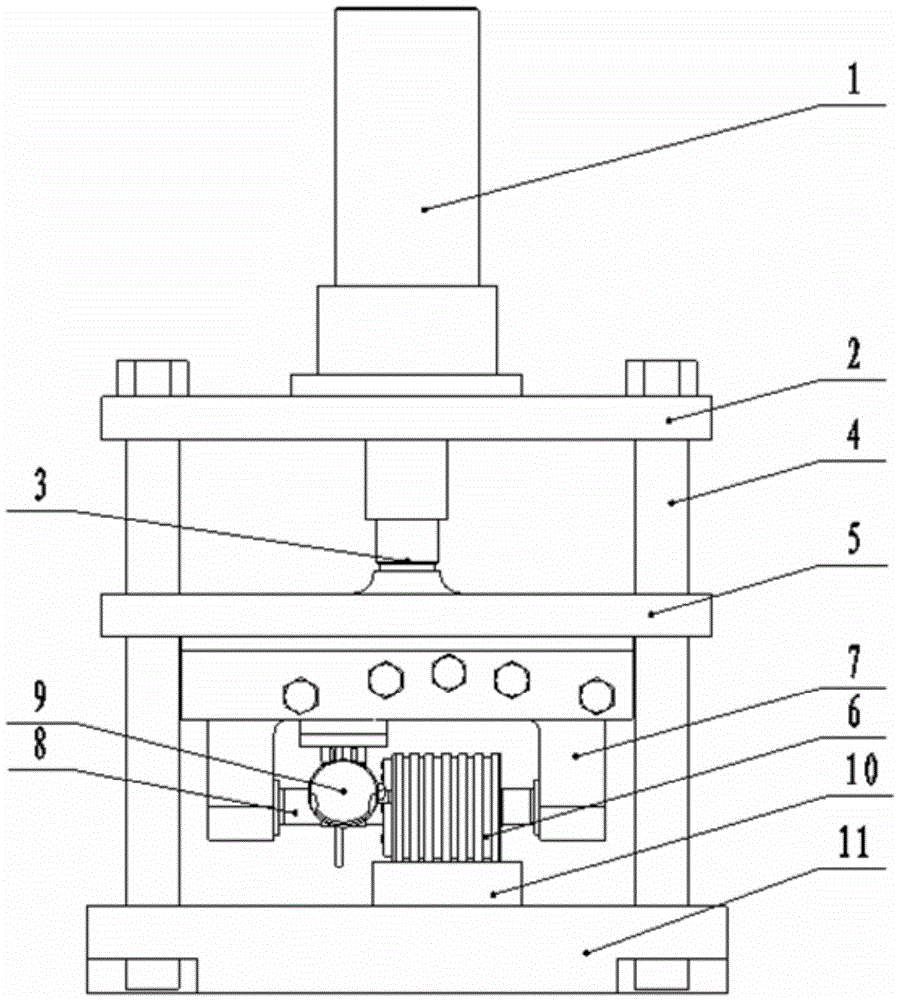

[0050] The loading device is mainly composed of a hydraulic cylinder 1, a fixed plate 2, a load sensor 3, a column 4, a movable plate 5, a rubber wheel 6, a loading head 7, a loading shaft 8, a brake 9, a force platform 10, a shaft sleeve 19 and a brake disc 20 compositions. The loading device is fixed on the upper surface of the ground plate 11 through four uprights 4 . And four columns 4 are used as guide rails for the movable plate 5 to move up and down, and can bear the load from the loading head at the same time.

[0051] In the loading device, the fixed plate 2 is fixedly installed on the top end surfaces of the four columns 4 . The hydraulic cylinder 1 is installed on the geometric center of the upper surface of the fixed plate 2 , and the telescopic rod of the hydraulic cylinder 1 passes through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com