Automatic meat paste hammering machine

A meat mashing machine and automatic technology, which is applied in meat processing, slaughtering, food science and other directions, can solve the problems of too soft and insufficient strength, no elastic hammering of free fall, insufficient cooling device for cooling, etc., and achieves simple and convenient mechanical structure. Continuous beating, easy cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

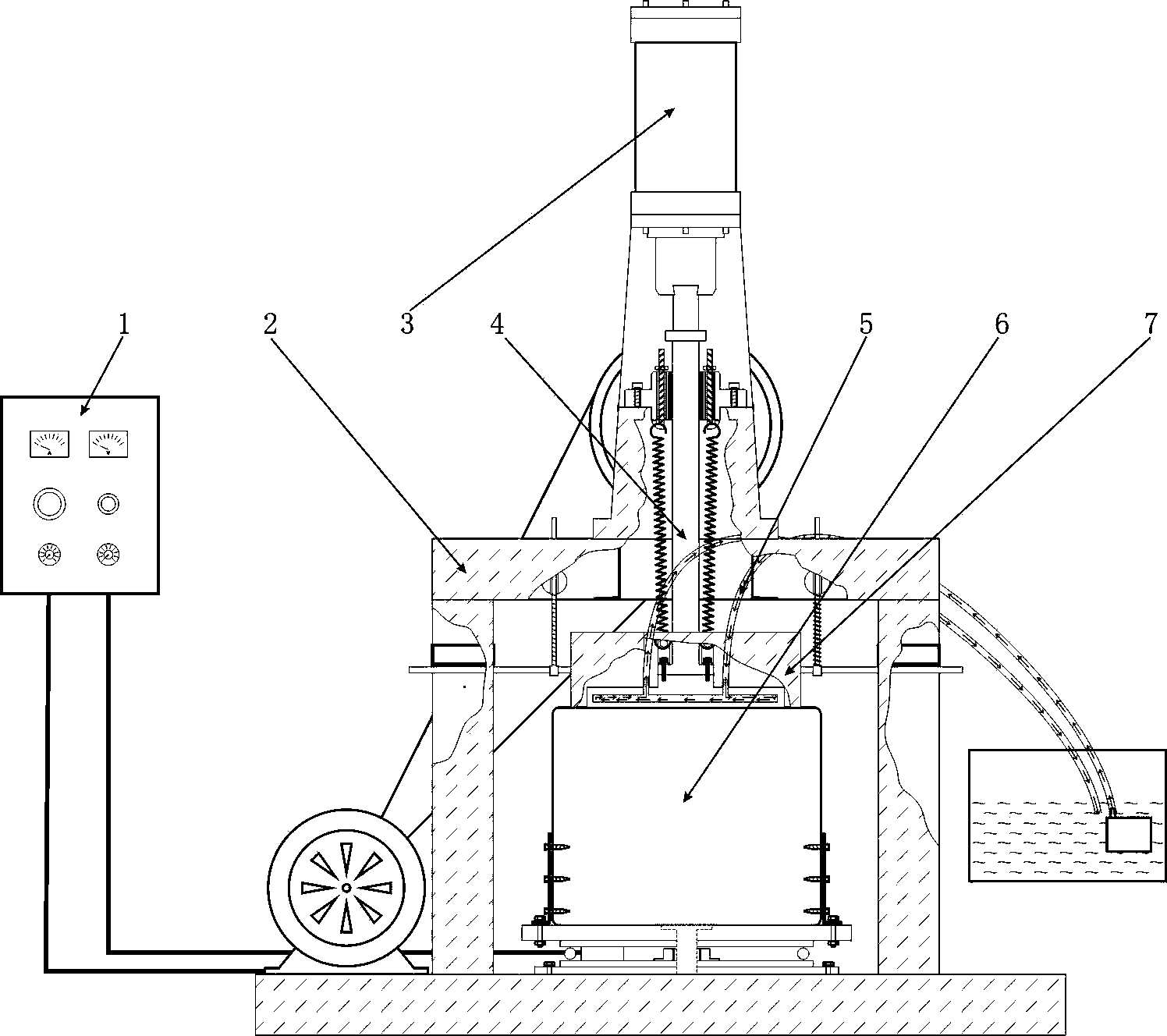

[0028] exist figure 1 Among them, the automatic meat paste beating machine includes a motor control device 1, a frame 2, an air hammer 3, an extension beating device 4, a cooling liquid circulation cooling circuit device 5 for a rectangular hammer rod, an anvil 6, a baffle device 7, and the like.

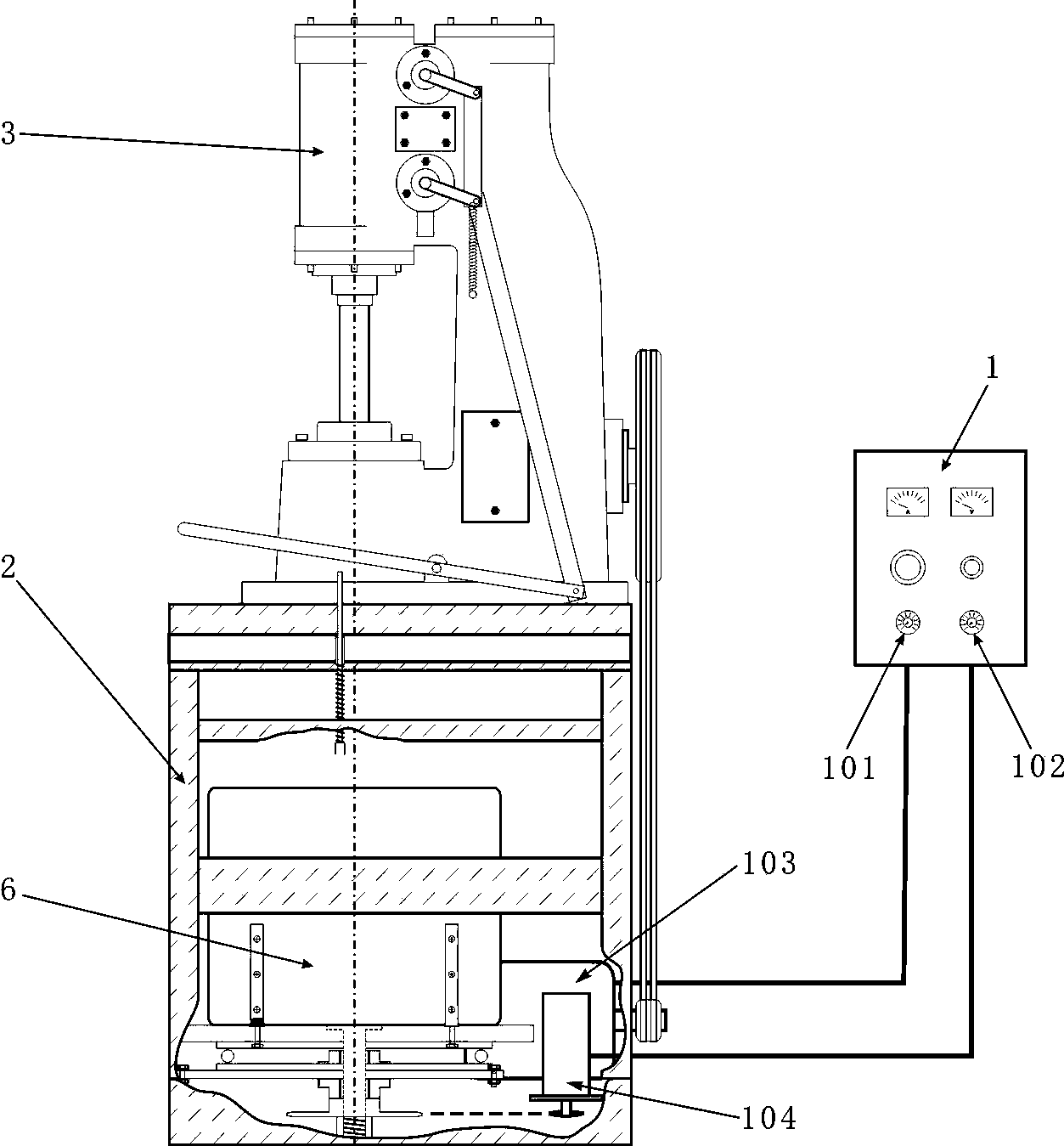

[0029] figure 2 In the shown embodiment, a frame 2 is made below the air hammer 3 to carry and fasten the air hammer, and a rotatable anvil 6 is arranged in the frame below the axis of the extended beating device of the air hammer, and the rotatable anvil is fastened to the frame. In the control device 1, the speed-adjustable knob 101 is allowed to control the motor 103 to allow the air hammer to provide beating power through the belt, and the speed-adjustable knob 102 is allowed to control the motor 104 to allow the sprocket to rotate the anvil through the chain.

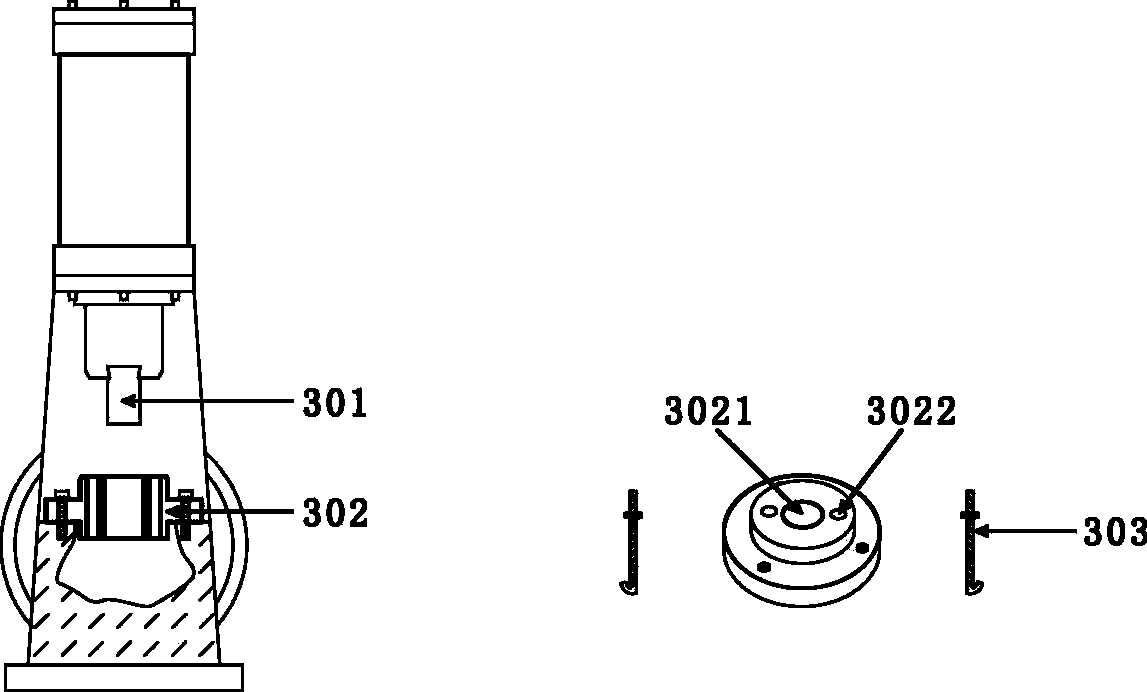

[0030] image 3 In the shown embodiment, a positioning bushing 3021 is made at the center of the anvil 302 below th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com