Biochemical composite additive

A compound and additive technology, which is applied in the shaping or processing of animal feed, additional food elements, storage methods of animal feed raw materials, etc., can solve the problems of unstable use effect and inconsistent use effect, and avoid the point of unstable effect , improve digestibility and inhibit reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

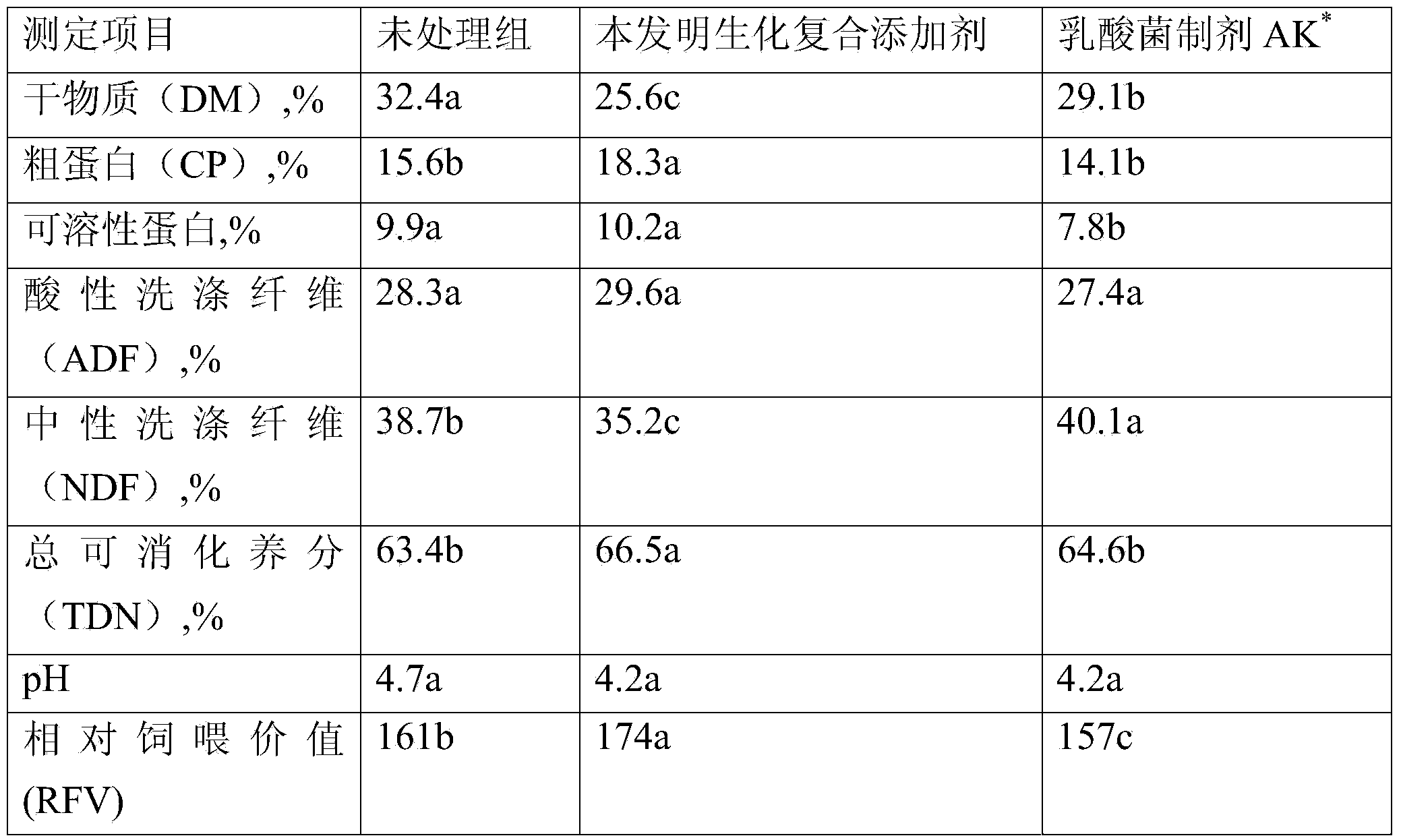

Image

Examples

Embodiment 1

[0021] 1. A biochemical composite additive, the components and mass fractions are: 0.85 parts of α-amylase, 80 parts of sodium sulfite, 4.0 parts of sodium bisulfite, 90 parts of potassium bisulfite, 90 parts of glucose, and 35 parts of bentonite.

[0022] 2. Preparation method:

[0023] (1) Take the α-amylase, glucose and bentonite of the above-mentioned mass parts, and fully mix it in a stirring device;

[0024] (2) Take the sulfur-containing compound (sodium sulfite, sodium bisulfite, potassium bisulfite) of the above mass parts and fully mix with a stirrer;

[0025] (3) Fully mix the raw materials prepared in steps (1) and (2) with a premix mixing device, and pack into bags to make a finished product.

[0026] 3. How to use:

[0027] Add 0.25 kg of the above-mentioned biochemical compound additive per ton of alfalfa silage raw material, and control the moisture content of alfalfa raw material at 65%.

Embodiment 2

[0035] 1. A biochemical compound additive, the components and mass fractions are: 2.0 parts of α-amylase, 130 parts of sodium sulfite, 3.0 parts of sodium bisulfite, 110 parts of potassium bisulfite, 75 parts of glucose, and 50 parts of calcium carbonate .

[0036] 2. Preparation method:

[0037] (1) Take the alpha-amylase, glucose and calcium carbonate of above-mentioned mass parts, fully mix it in stirring equipment;

[0038] (2) Take the sulfur-containing compound (sodium sulfite, sodium bisulfite, potassium bisulfite) of the above mass parts and fully mix with a stirrer;

[0039] (3) Fully mix the raw materials prepared in steps (1) and (2) with a premix mixing device, and pack into bags to make a finished product.

[0040] 3. How to use:

[0041] Add 0.35 kg of the above-mentioned biochemical compound additive per ton of alfalfa silage raw material, and control the moisture content of alfalfa raw material at 70%.

Embodiment 3

[0049] 1. A biochemical compound additive, the components and mass fractions are: 1.5 parts of α-amylase, 150 parts of sodium sulfite, 5.0 parts of sodium bisulfite, 125 parts of potassium bisulfite, 55 parts of glucose, and 65 parts of calcium carbonate .

[0050] 2. Preparation method:

[0051] (1) Take the α-amylase, glucose and feed additive carrier raw materials of the above-mentioned parts by mass, and fully mix them in a stirring device;

[0052] (2) Take the sulfur-containing compound (sodium sulfite, sodium bisulfite, potassium bisulfite) of the above mass parts and fully mix with a stirrer;

[0053] (3) Fully mix the raw materials prepared in steps (1) and (2) with a premix mixing device, and pack into bags to make a finished product.

[0054] 3. How to use:

[0055] Add 0.5 kg of the above-mentioned biochemical compound additive per ton of alfalfa silage raw material, and control the moisture content of alfalfa raw material at 68%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com