Feed placing mechanism, sieving machine and filling device for electric initiating explosive device granules

A technology for filling equipment and granular materials, which is applied in the fields of sieving, solid separation, chemical instruments and methods, etc., can solve the problems of high safety risk, high production labor intensity, explosiveness, etc., to reduce safety risks, prevent static electricity accumulation, The effect of increasing the bulk density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

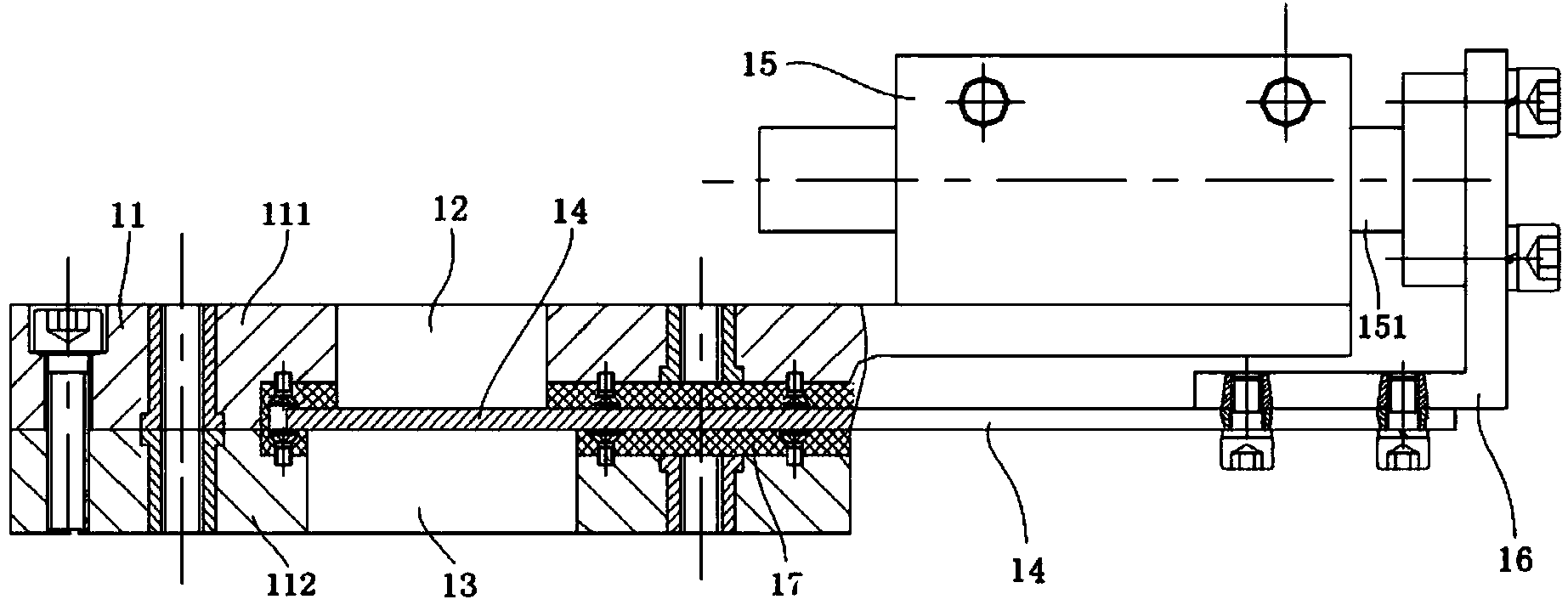

[0033] see figure 1 , the discharge mechanism of this embodiment includes an upper bracket 111 with an upper feeding hole 12, a lower bracket 112 with a lower feeding hole 13, an opening and closing cylinder 15, a cylinder piston 151, a connecting piece 16, and a discharging plate 14 And conductive sealing ring 17.

[0034] The upper bracket 111 and the lower bracket 112 are closely matched to form the working plate 11. The diameter of the upper feed hole 111 is smaller than the diameter of the lower feed hole 112 to prevent the material from being blocked during the feeding process. The opening and closing cylinder 15 is installed on the upper bracket 111. The cylinder piston 151 is fixedly connected to the connection piece 16, and the connection piece 16 is connected to the discharge plate 14. The discharge plate 14 passes between the conductive sealing gaskets 17, and the discharge insertion plate 14 is closely matched with the conductive sealing gasket 17, so that the elec...

Embodiment 2

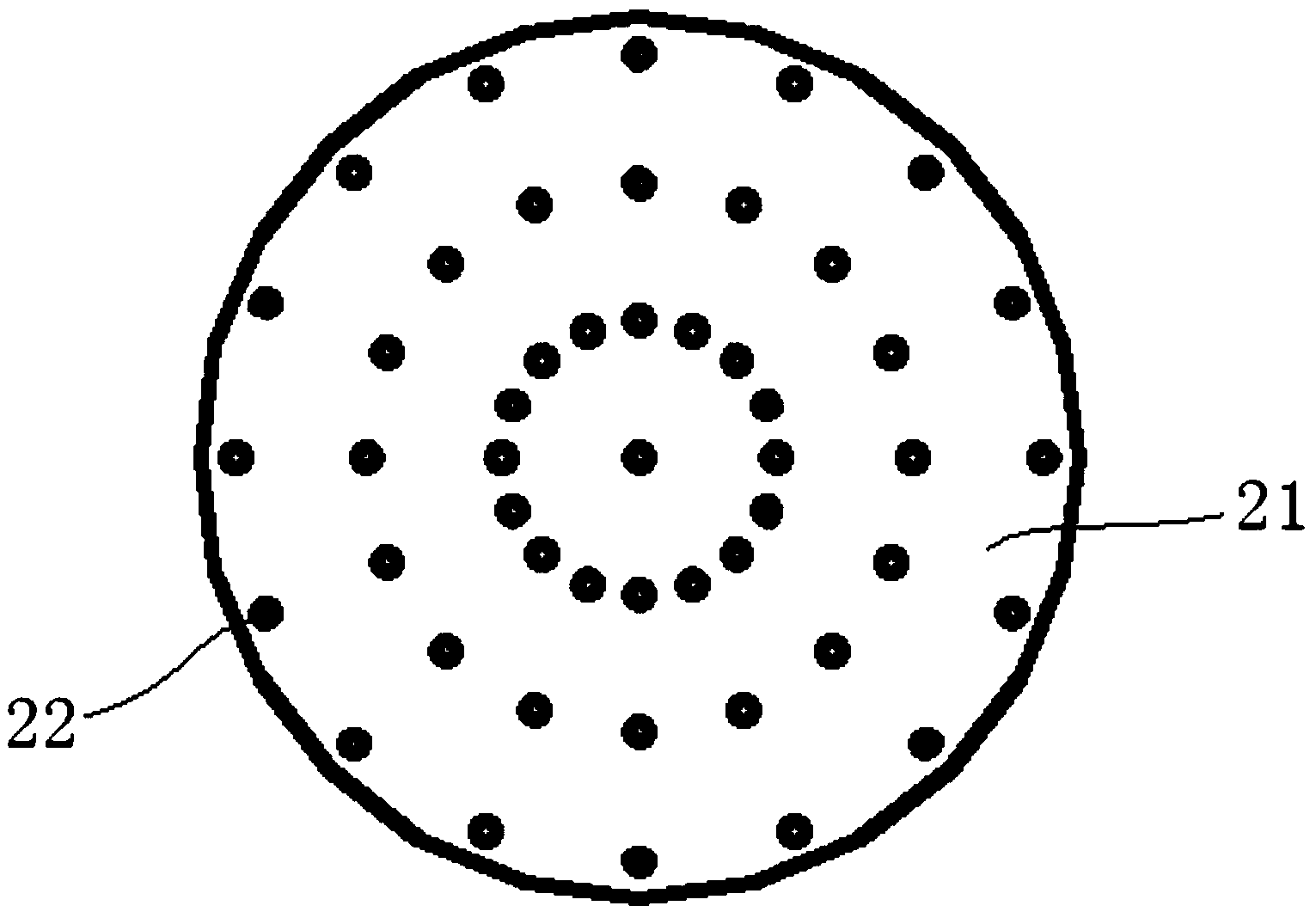

[0037] see figure 2 , the sifter of this embodiment includes a circular sieve cylinder, the inner diameter of which is 900mm, and the inner diameter is 700mm. Two sieve plates are installed up and down in the sieve cylinder, and a plurality of sieve holes 22 are evenly distributed on each sieve plate 22 . The upper and lower distance between the two sieve plates is 30cm, the diameter of the sieve holes is 15mm, and the number of sieve holes per unit area is 100 holes / cm 2 .

[0038] When the propellant cast particles flow into the sieve, the cast particles flow through the sieve plate and the sieve holes of the sieve plate in turn, and then flow into the mold, so that the flow speed of the cast particles can be controlled to increase the filling density of the propellant cast particles in the mold the goal of.

Embodiment 3

[0040] see figure 2 , the sifter of this embodiment includes a circular sieve cylinder, the inner diameter of which is 900mm, and the inner diameter is 800mm. A sieve plate is installed up and down in the sieve cylinder, the diameter of the sieve hole is 10mm, and the number of sieve holes per unit area is 150 holes / cm 2 .

[0041] When the propellant cast particles flow into the sieve, the cast particles flow through the sieve plate and the sieve holes of the sieve plate in turn, and then flow into the mold, so that the flow speed of the cast particles can be controlled to increase the filling density of the propellant cast particles in the mold the goal of.

[0042] Example 3:

[0043] The processing capacity of the propellant casting particle filling equipment of this embodiment is 100-130 Kg / h.

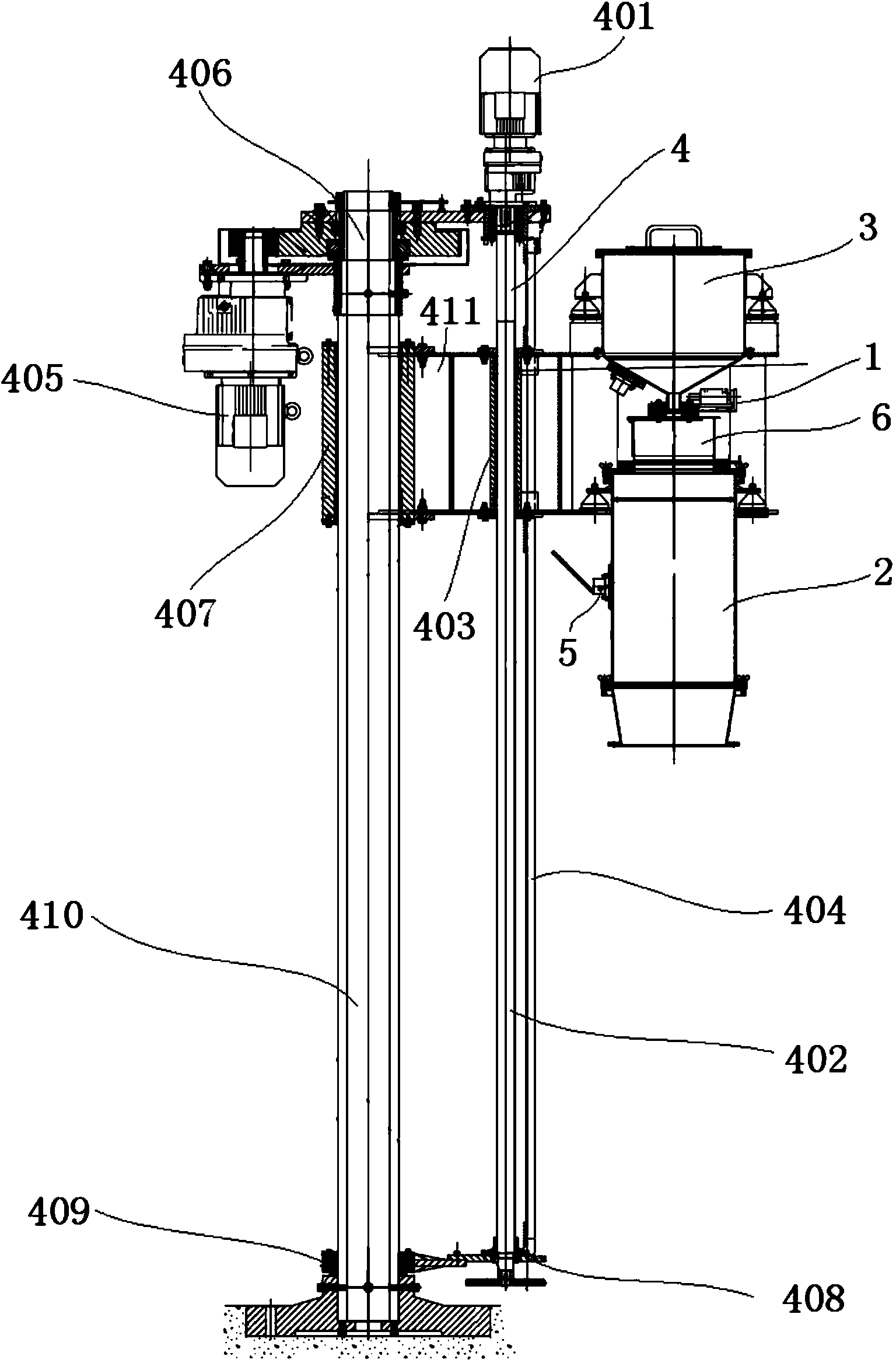

[0044] refer to image 3 , the propellant casting particle filling equipment of this embodiment includes a barrel 3, the discharge mechanism 1 in embodiment 1, the sieve d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com