Clamp used for welding beam of bogie of railway vehicle

A rail vehicle and bogie technology, which is applied in the field of fixtures for rail vehicle bogie beam welding, can solve problems such as bogie welding defects, large bogie volume, and uneven weld seams, and achieve simple structure, guaranteed mechanism, and guaranteed safety sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment, further clarifies the present invention, and this practical example is carried out under the premise of the technical solution of the present invention, understands that these embodiments are only for illustrating the present invention and are not intended to limit the scope of the present invention.

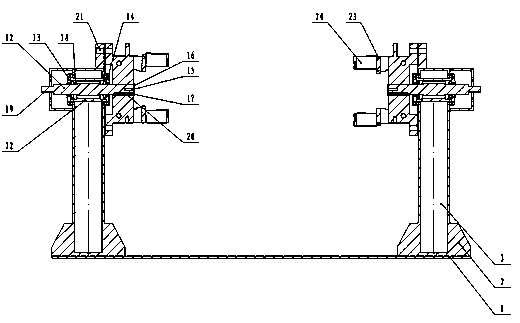

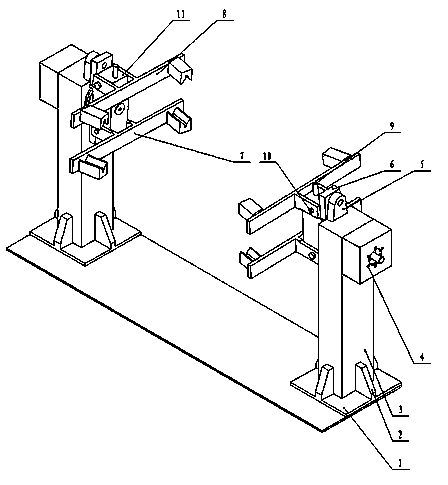

[0014] like figure 1 and figure 2 As shown, a fixture for rail vehicle bogie beam welding includes a support base, a rotating device, and a clamping device; the support base is provided with a base 1, a rib plate 2, a support base 3 and a first fixing Seat 5, the base 1 is set on the ground, the base 1 is provided with a support seat 3, the rib plate 2 is evenly arranged above the base 1, the rib plate 2 and the support seat 3 are connected to the base by welding, and the support seat 3 is provided with a second A fixed seat 5; the rotating device is provided with a worm gear reducer 4, a connectin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com