Bi-directional eccentric crankshaft center hole processing clamp

A center hole and crankshaft technology, applied in the field of two-way eccentric crankshaft processing fixtures, can solve problems such as difficult to achieve machining accuracy, size and technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

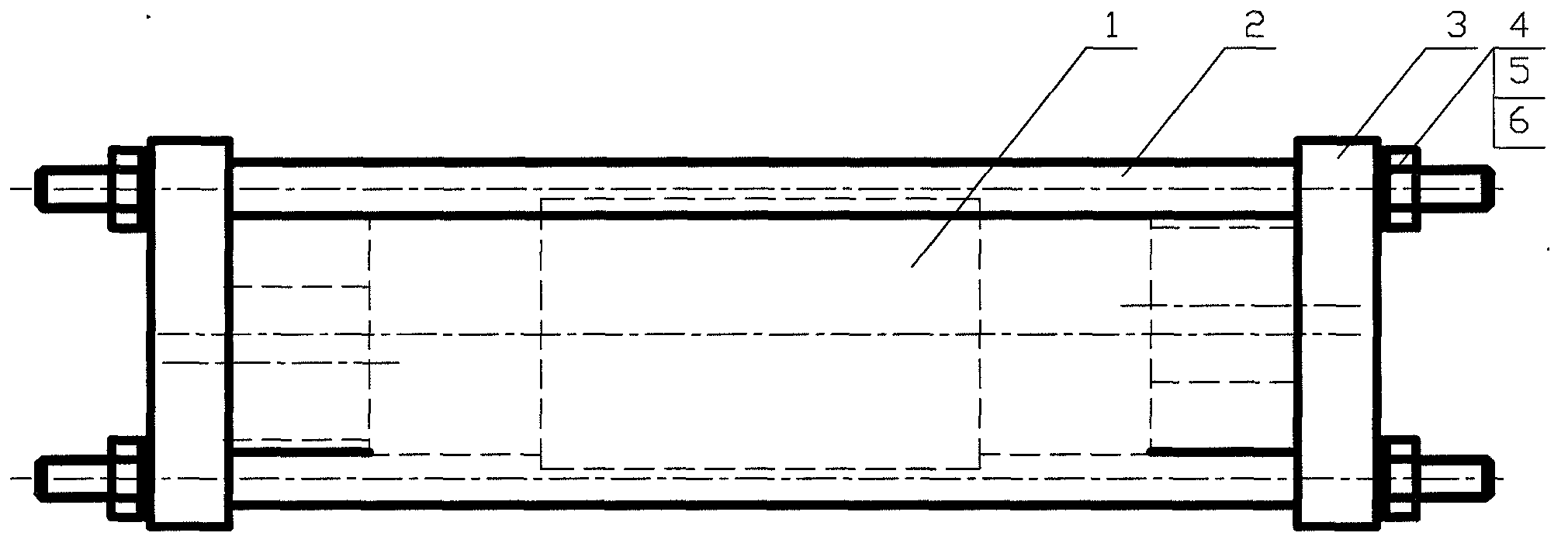

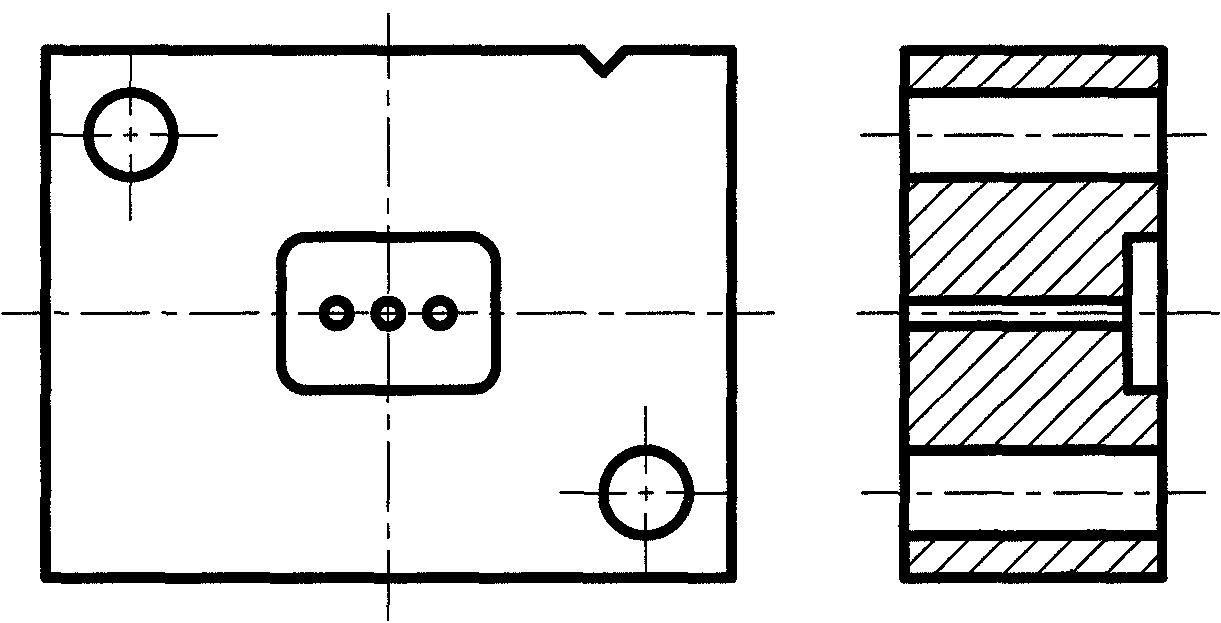

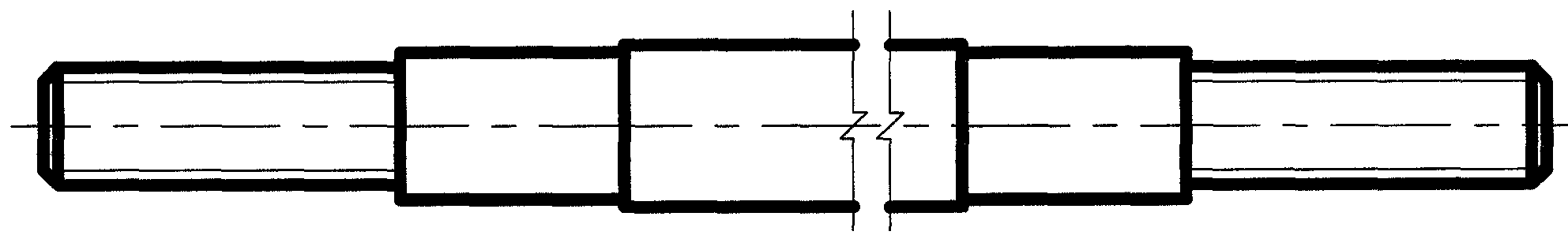

[0011] The two-way eccentric crankshaft ( figure 1 Middle 1) placed on the center hole processing guide plate ( figure 1 Middle 3) in the middle, through the connecting rod ( figure 1 Middle 2), flat pad ( figure 1 Middle 4), spring washer ( figure 1 5) and nut ( figure 1 Middle 6) connect into a whole, fix this whole on the drilling machine, and the drill bit processes the guide plate through the center hole ( figure 1 Middle 3) It can quickly and accurately locate, drill and process three center holes, and use the double top to pass the center hole to move the two-way eccentric crankshaft ( figure 1 Middle 1) The top is clamped on the ordinary lathe to complete the turning process of the two-way eccentric crankshaft.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com