Manipulator based on spherical screw pair

A technology of manipulator and helical pair, which is applied in the field of manipulator based on spherical helical pair, can solve problems such as difficulty in guaranteeing the safety performance of jaws

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

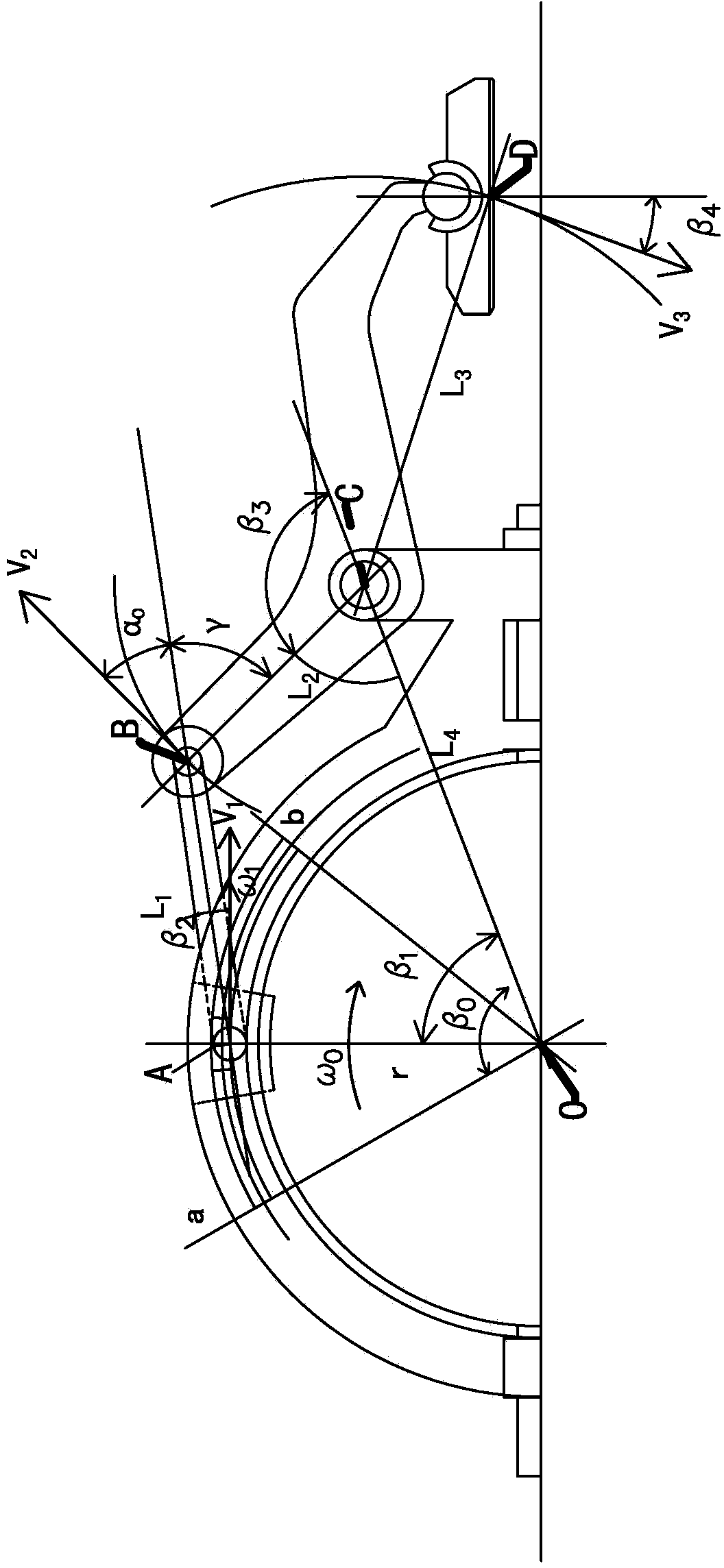

[0024] see Figure 1-7 As shown, the embodiments of the present invention will be described in detail.

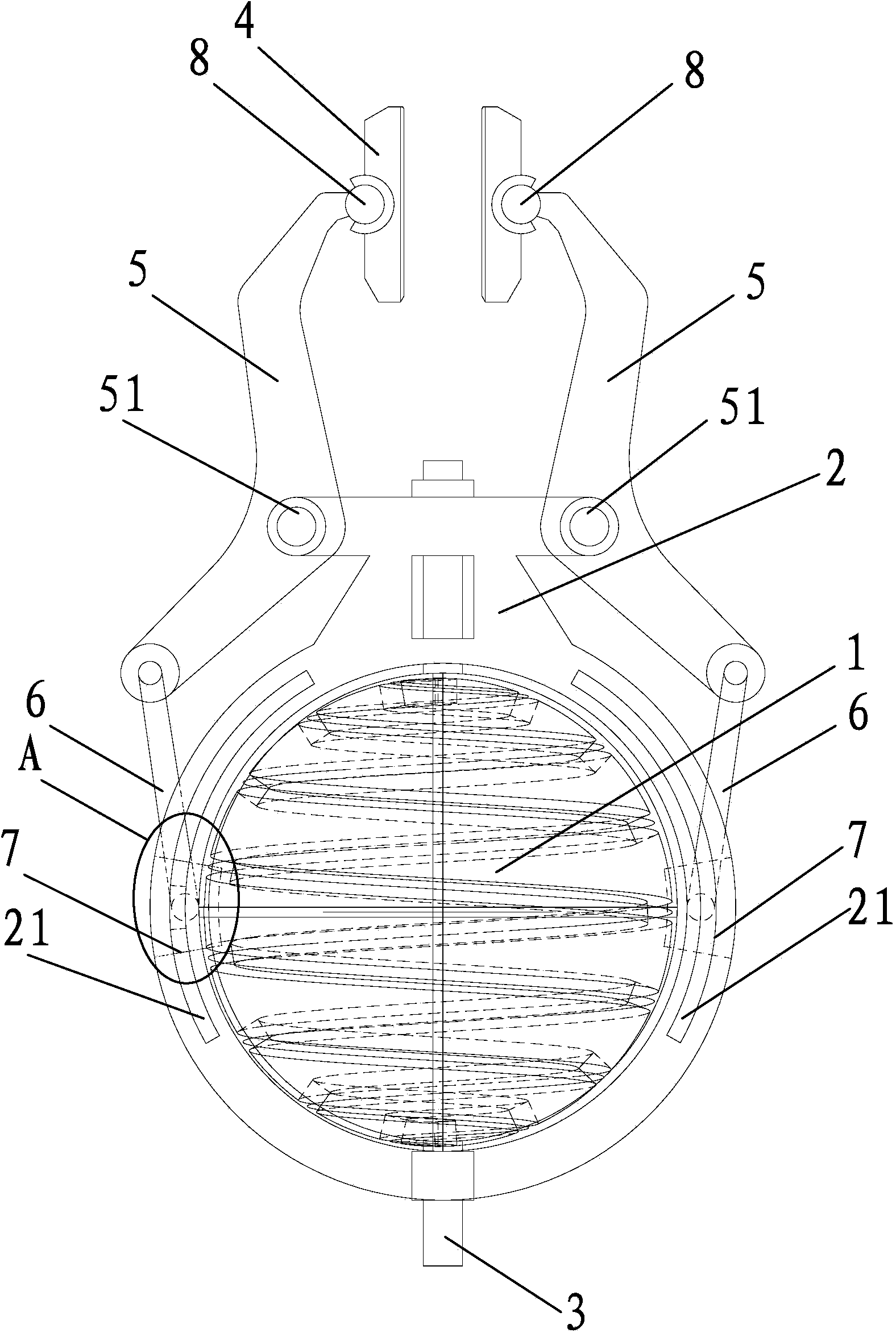

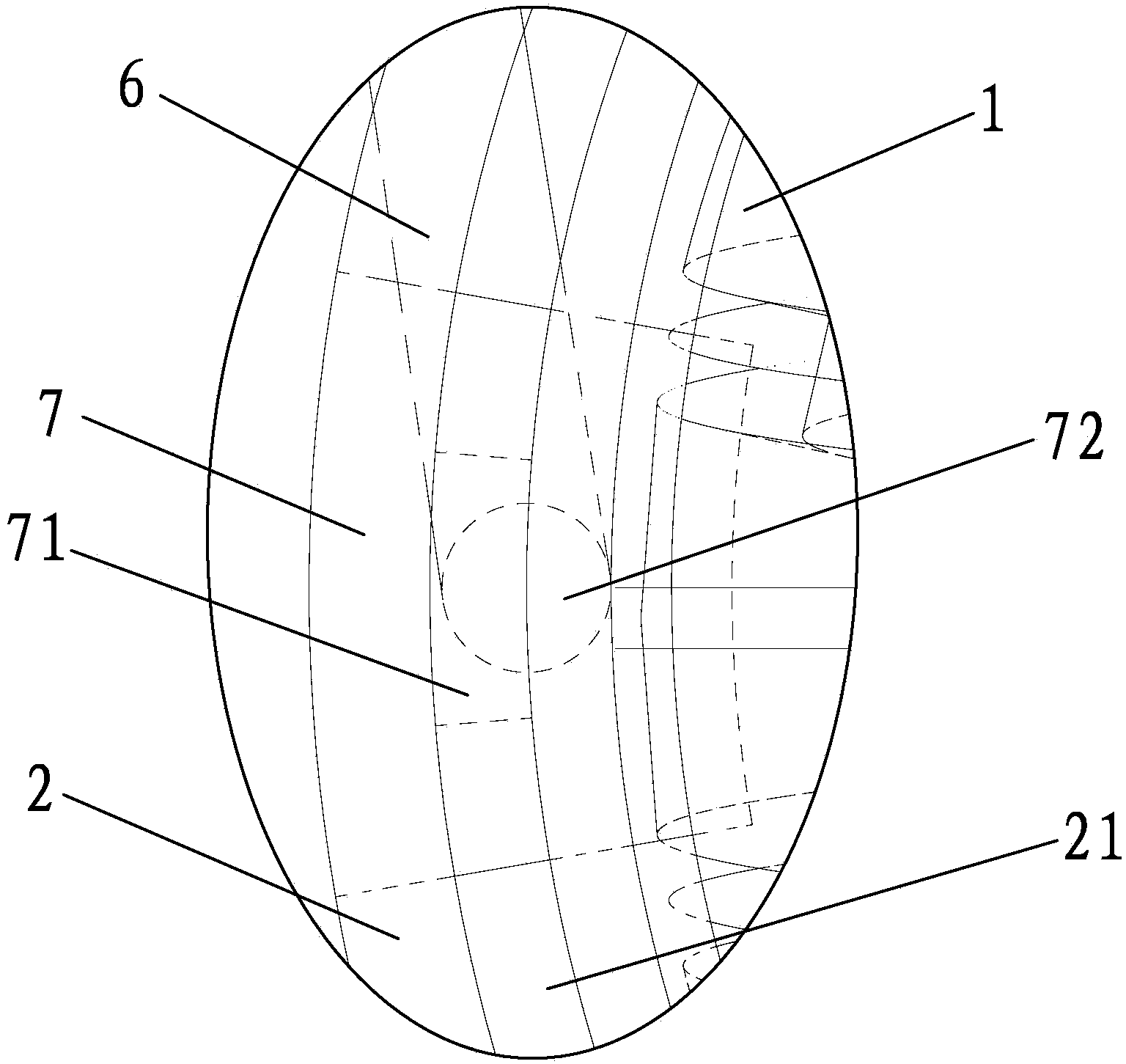

[0025] key reference Figure 1~2 , the present invention relates to a manipulator based on a spherical screw pair, the manipulator includes a ball helix 1, a frame mechanism 2, a rotating shaft 3, two jaws 4, two clamping beams 5 and two connecting rods 6, the The ball helix 1 is arranged in the frame mechanism 2, the rotating shaft 3 is connected to the bottom of the ball helix 1, and the frame mechanism 2 is respectively provided with an arc-shaped chute 21 along both sides of the ball helix 1, two sliders 7 is embedded in the corresponding chute 21 through the convex key 71, each of the sliders 7 is slidingly engaged with the ball helical groove 11 on the ball helix 1, and each of the sliders 7 is connected to the corresponding chute through a connecting rod 6. One end of the clamping beam 5 is pivotally connected, and the other end of each clamping beam 5 is linked wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com