Full-automatic electromagnetic punching machine

A fully automatic and electromagnetic technology, applied in the field of machine tools, can solve the problems of rapid downward impact of the sliding whole, easy damage to operators and molds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

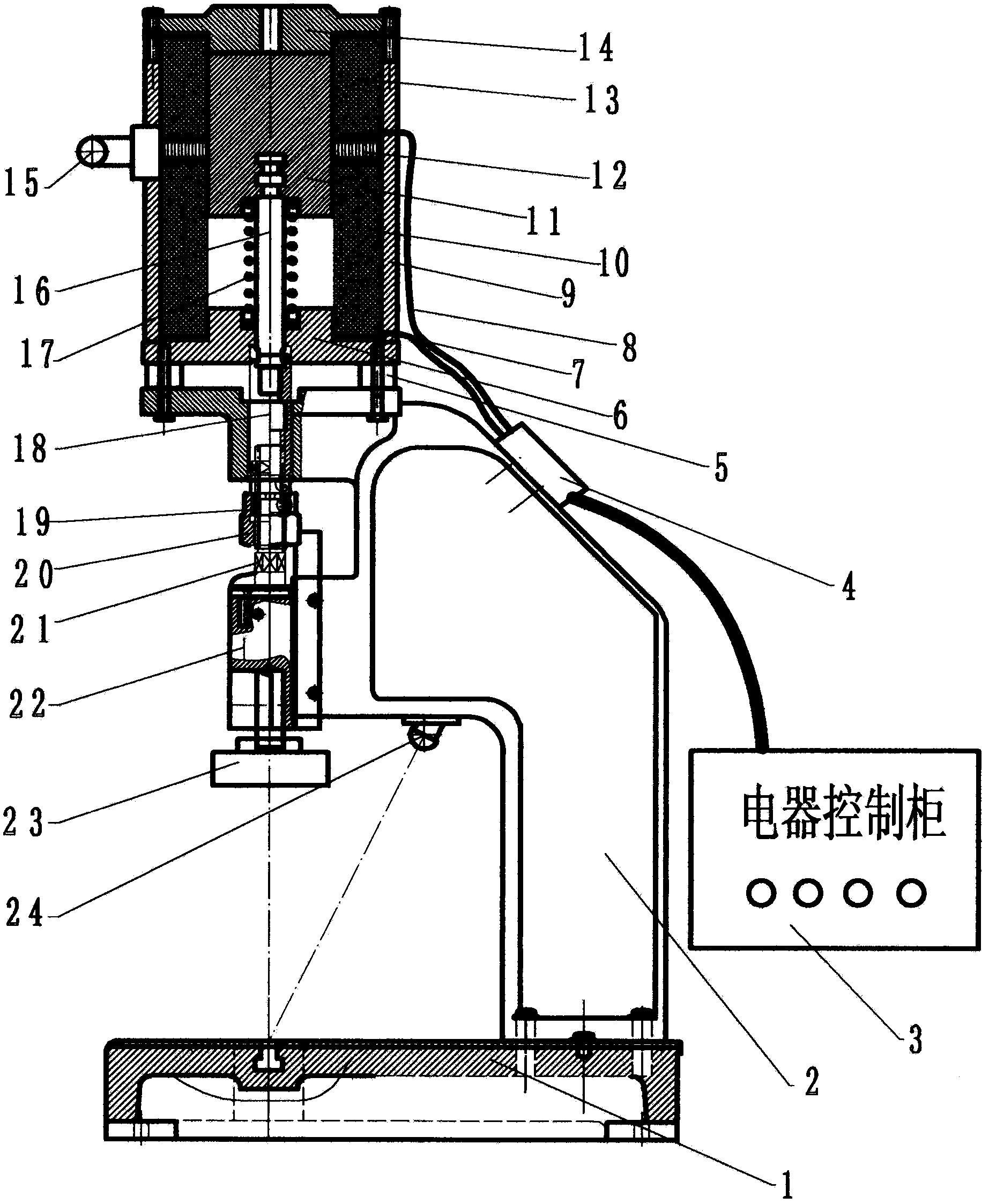

[0013] figure 1 As shown, the body 2 is installed above the base 1, and the electromagnetic power machine 9 is supported by the magnetic isolation pad 5 at the upper end of the body 2. , Suction and pull return coil 13, armature 11, brake pad 12, electromagnetic braking device 15 are formed.

[0014] When static, the armature 11 is positioned at the upper end of the electromagnetic power machine 9, and is braked by the brake pad 12. During dynamic operation, the electric control cabinet (3) supplies power to the main power coil 10 and the electromagnetic brake device 15, and now the brake pad (12) is opened. At the same time, the active power coil (10) generates a strong magnetic field concentrated on the lower pole piece (6), which pulls the armature (11) downwards to be the energy impact of the masonry force, and completes a stamping. At this time, the electrical control cabinet (3) Turn off the pulse current of the main power coil (10) and the electromagnetic brake device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com