Dumper rear vehicle

A technology for dump trucks and rear trucks, which is applied to vehicle parts, vehicles with tilted bearing movement, and substructures. It can solve problems such as the decline in the load capacity of dump trucks and the unreasonable design and layout of cargo boxes, so as to improve the service life and prevent serious accidents. Safety accidents and the effect of improving carrying capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

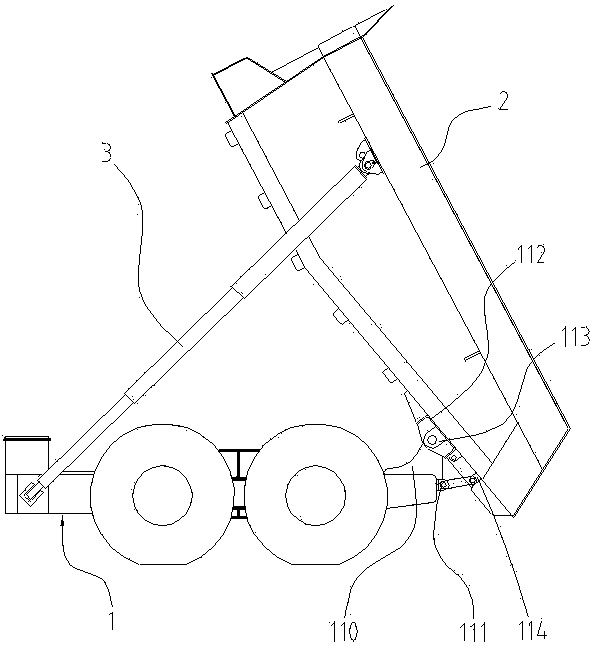

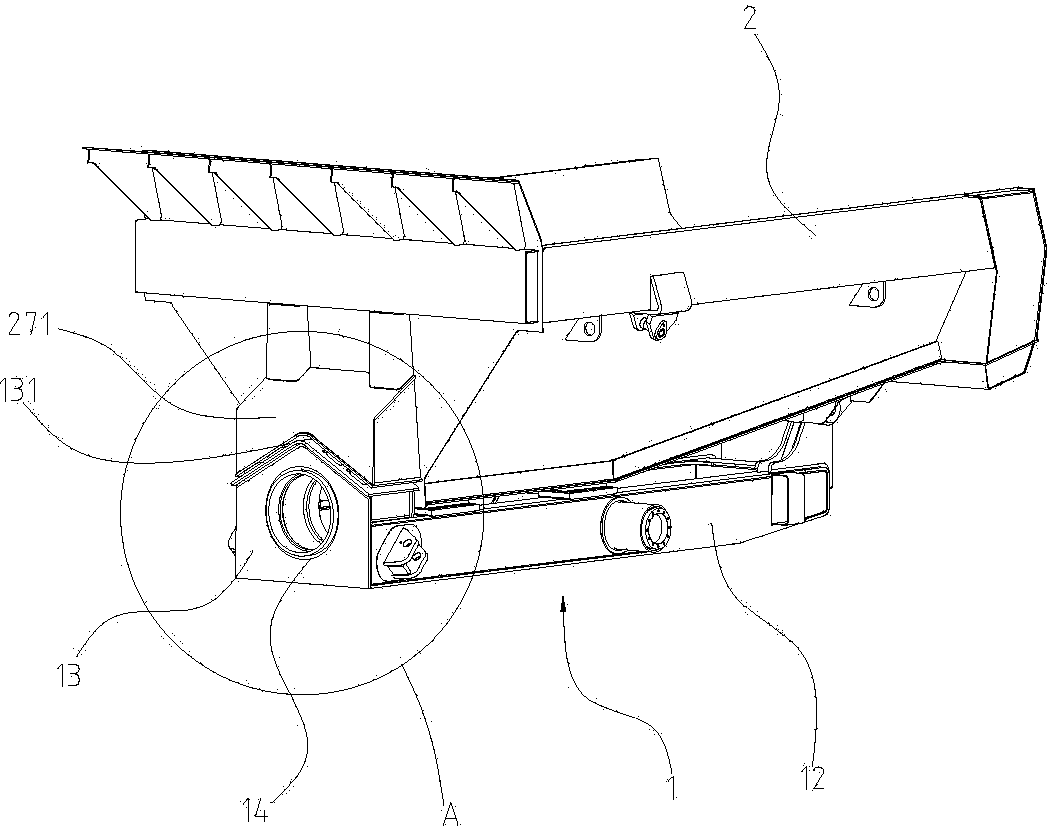

[0029] Such as figure 1 As shown, a rear car of a dump truck includes a rear frame 1, a cargo box 2 arranged on the rear frame 1 and a hydraulic lifting system for lifting the cargo box, and the rear end of the cargo box 2 is connected to the The rear vehicle frame is hinged, and the front end of the rear vehicle frame 1 is provided with a container positioning device for positioning the container.

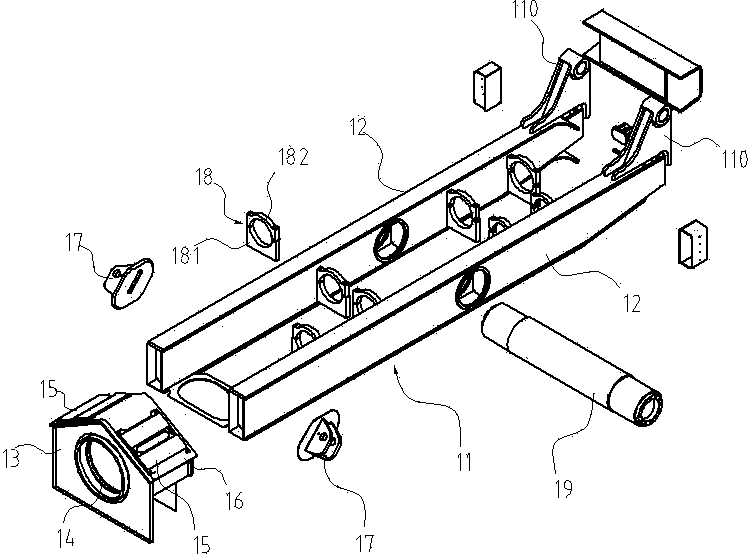

[0030] Such as figure 2 , 3 As shown, the rear frame includes two symmetrically arranged longitudinal beam assemblies 11, the longitudinal beam assembly 11 includes a rear vehicle longitudinal beam 12, and the rear vehicle longitudinal beam 12 is a box-shaped structure with reinforcing ribs inside. plate. The outer side of the rear vehicle longitudinal beam 12 is provided with a rear frame lifting support 17 and a rear frame anti-torque pipe 19; the rear frame lifting seat 17 is used for installing a hydraulic rod, and the rear frame is torsion-resistant. Pipe 19 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com