Composition of touch control cover glass

A technology of protective glass and touch control, which is applied in the field of composition of touch protective glass, and can solve problems such as high energy consumption, reduced production costs, and glass that does not meet environmental protection standards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

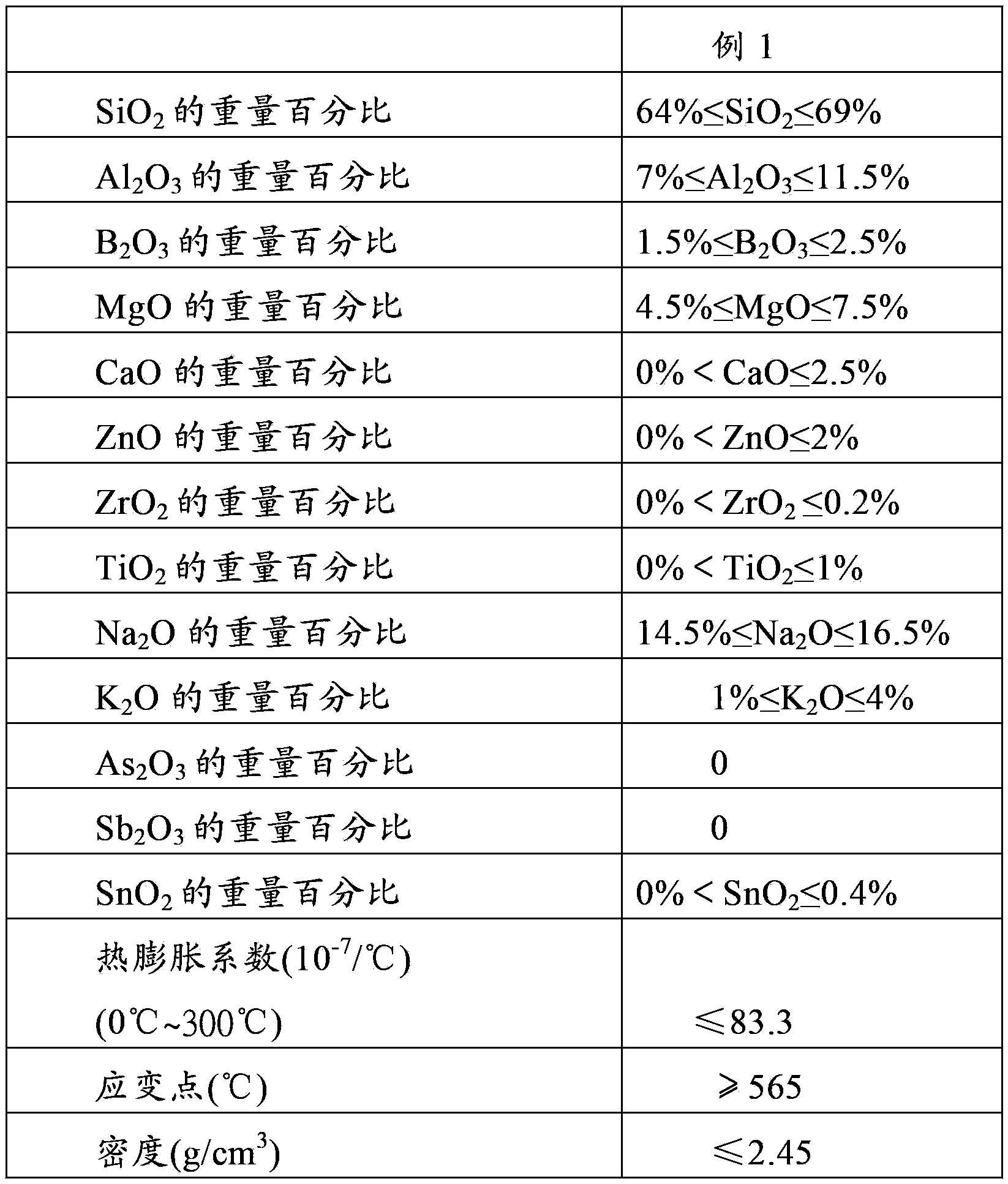

[0009] The present invention mainly provides a composition of a touch protection glass. The touch protection glass is composed of the following materials (components) according to a certain weight percentage:

[0010] (1) Weight percentage 64%≤SiO 2 ≤69%;

[0011] (2) Weight percent 7%≤Al 2 o 3 ≤11.5%;

[0012] (3) weight percentage 1.5%≤B 2 o 3 ≤2.5%;

[0013] (4) weight percentage 4.5%≤MgO≤7.5%;

[0014] (5) Weight percentage 0%

[0015] (6) Weight percentage 0%

[0016] (7) Weight percent 0%2 ≤0.2%;

[0017] (8) weight percentage 0%2 ≤1%;

[0018] (9) weight percentage 14.5%≤Na 2 O≤16.5%;

[0019] (10) weight percentage 1%≤K 2 O≤4%;

[0020] (11) weight percentage 0%2 ≤0.4%; and

[0021] (12) Among them, the total weight percentage of CaO and MgO is the best at 4.5% to 10%, and Na 2 O and K 2 The total weight percentage of O is optimal at 15.5% to 20.5%.

[0022] In the present invention, because the weight percentage of each component wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strain point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com