Optical glass, glass prefabricated member or optical element prepared from the optical glass, and optical instrument

A technology for optical glass and optical components, applied in optical components, instruments, optics, etc., can solve the problem of high-refractive and low-dispersion optical glass being easily devitrified and difficult to mass-produce, and achieve the effect of devitrification resistance and easy mass production.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

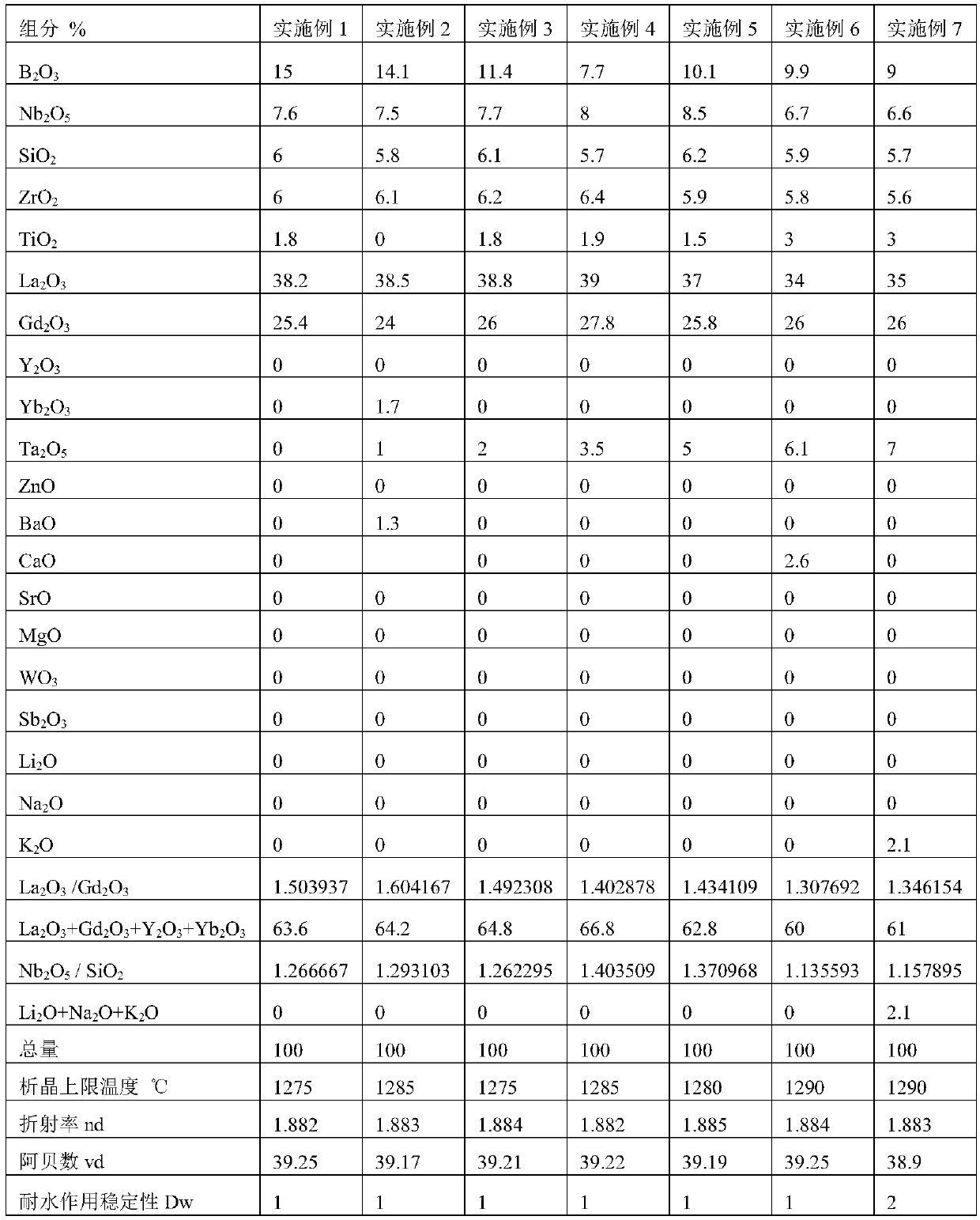

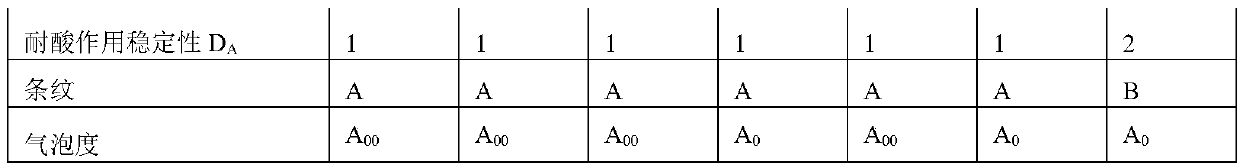

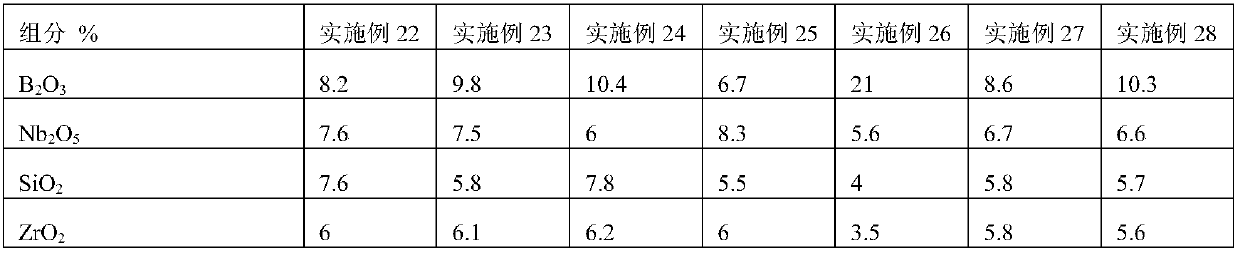

[0051] Optical glass embodiment

[0052] In order to obtain glass having the composition shown in Tables 1 to 6, carbonate, nitrate, hydroxide, oxide, boric acid, etc. are used as raw materials, and the raw materials corresponding to the optical glass components are weighed in proportions. After being thoroughly mixed, it becomes a blended raw material. The blended raw material is put into a platinum crucible, heated to 1200~1450°C, melted, stirred, and clarified to form a uniform molten glass, and then the molten glass is moderately cooled before pouring Into a preheated mold and hold at 650 to 700°C for 2 to 4 hours, then slowly cool to obtain an optical glass. In addition, the characteristics of each glass were measured by the methods shown below, and the measurement results are shown in Tables 1 to 6.

[0053] (1) The upper limit temperature of crystallization

[0054] The crystallization performance of the glass was measured by the temperature gradient furnace method. The glas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| crystallization temperature | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| Abbe number | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com