Optical glass, glass prefabricated member or optical component prepared therefrom, and optical instrument

A technology of optical glass and optical components, applied in optical components, optics, instruments, etc., can solve the problems of high cost, easy devitrification of glass, and high difficulty in mass production, and achieve low production cost, devitrification resistance, and easy mass production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

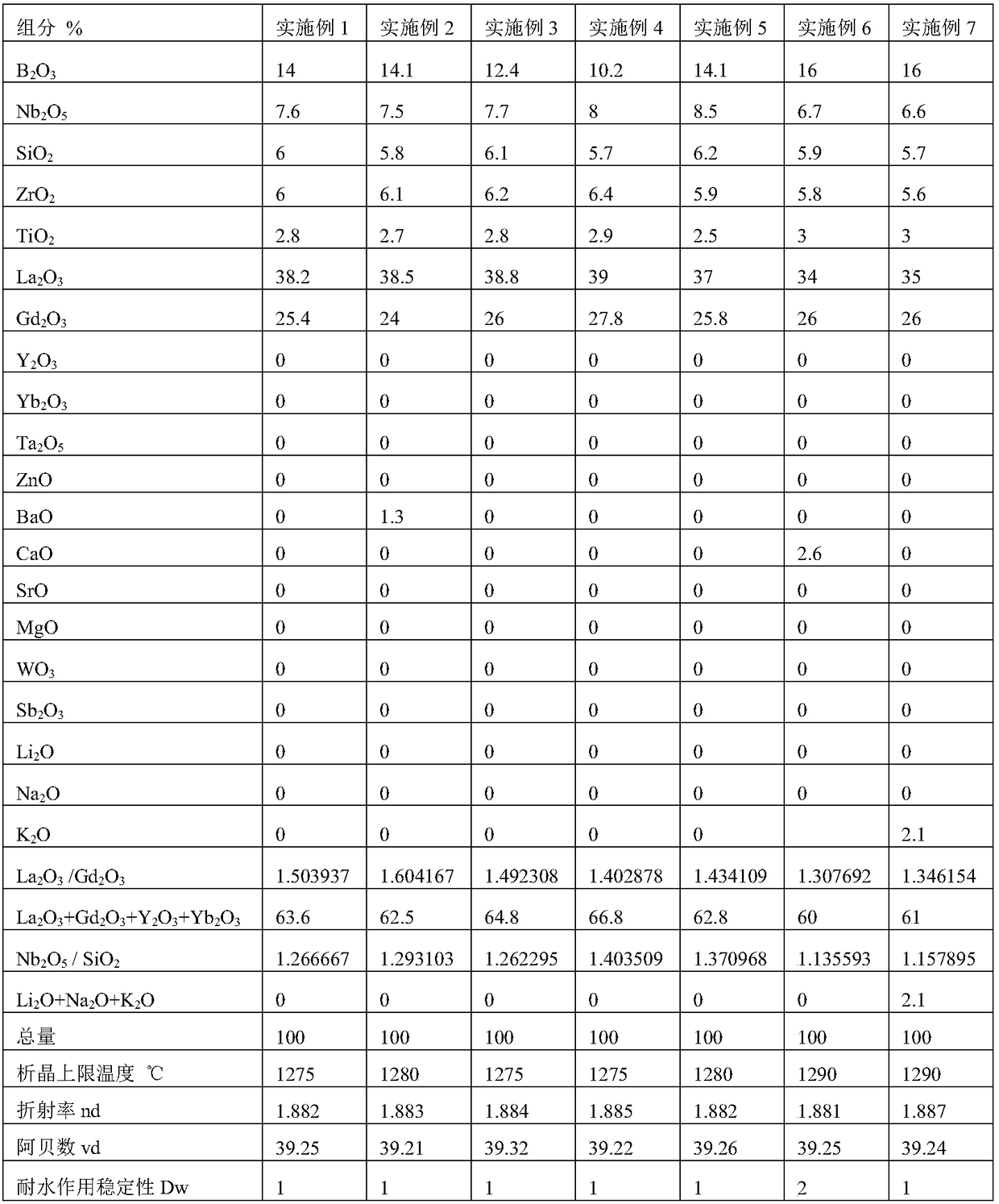

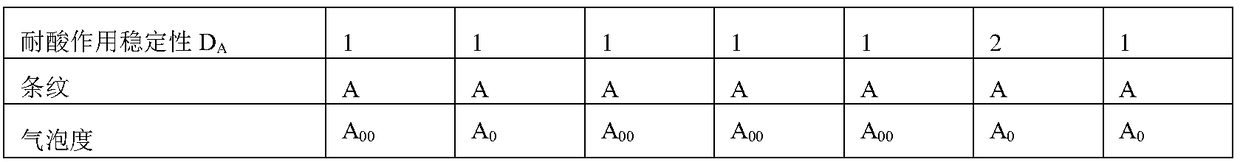

[0052] Examples of Optical Glass

[0053] In order to obtain glasses with the compositions shown in Tables 1 to 6, carbonates, nitrates, hydroxides, oxides, boric acid, etc. are used as raw materials, and the raw materials corresponding to the optical glass components are weighed in proportion to each raw material, After being fully mixed, it becomes a blending raw material, which is put into a platinum crucible, heated to 1200-1450°C, melted, stirred, and clarified to form a uniform molten glass, and then the molten glass is moderately cooled After pouring into a preheated mold and keeping it at 650-700°C for 2-4 hours, slow cooling is performed to obtain optical glass. Moreover, the characteristic of each glass was measured by the method shown below, and the measurement result is shown in Table 1-Table 6.

[0054] (1) Crystallization upper limit temperature

[0055] The crystallization performance of the glass is measured by the temperature gradient furnace method. The gla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com