Yarn sizing device capable of separating yarns

A yarn and yarn separation technology, which is applied in the direction of processing textile material yarn guide device, liquid/gas/vapor yarn/filament processing, processing textile material carrier, etc., can solve the problem of yarn sticking together and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

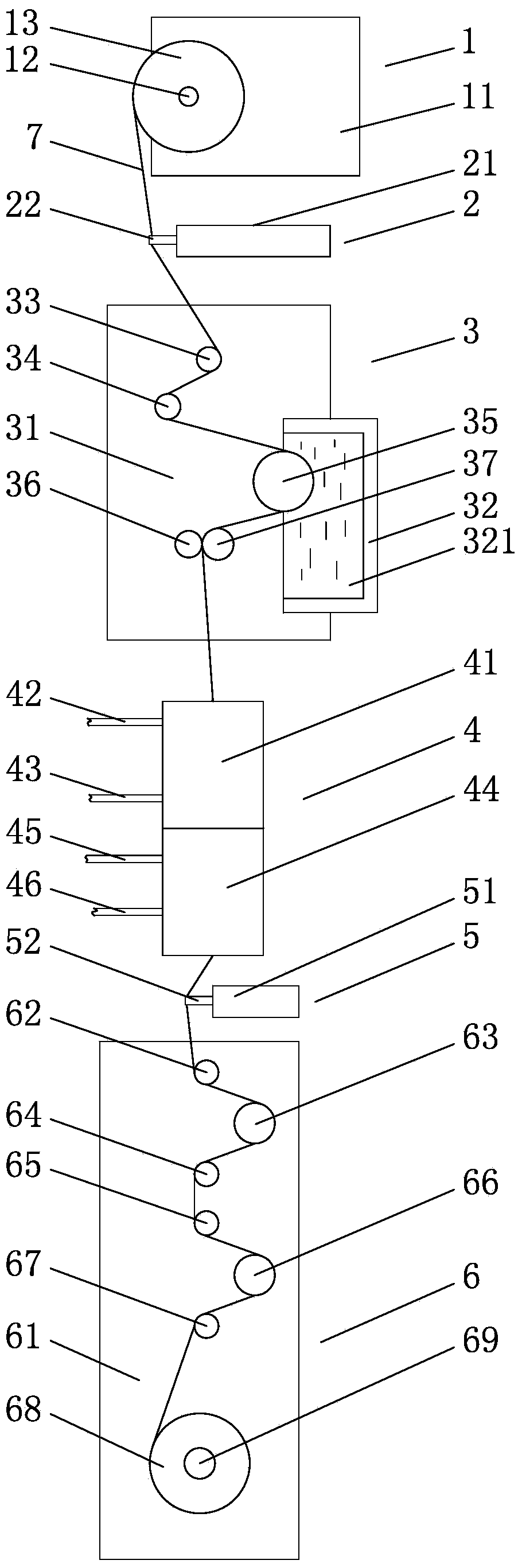

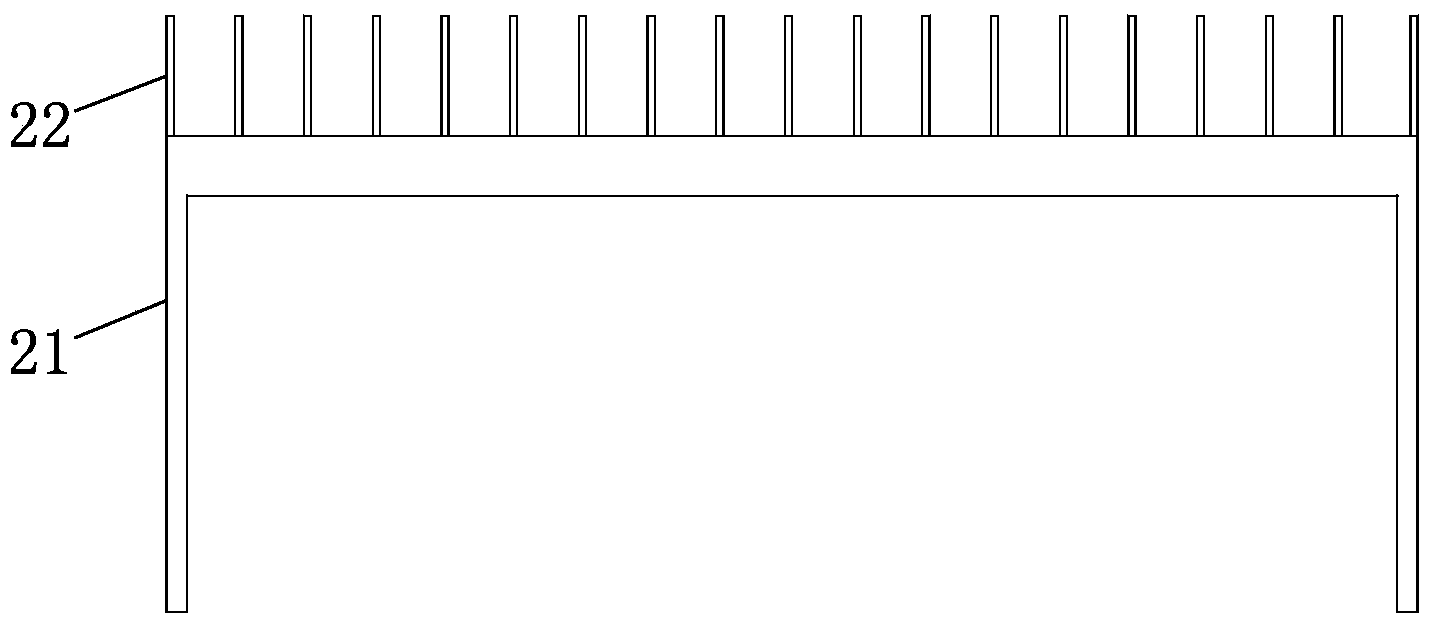

[0019] refer to figure 1 with figure 2 , a yarn sizing device that can be divided into yarns, including a discharging device 1, a first yarn dividing device 2, a sizing device 3, a drying device 4, a second yarn dividing device 5 and a yarn receiving device 6 arranged in sequence, the first A yarn dividing device 2 includes a first yarn dividing frame 21 and a first yarn dividing rod 22 evenly arranged on the first yarn dividing frame 21. The first yarn dividing rod 22 protrudes upwards to prevent the yarn 7 from falling from the first yarn dividing frame. Dropped on Rack 21. The yarn 7 drawn out from the yarn barrel 13 passes through and is in close contact with the side wall of the first yarn dividing rod 22 . The second yarn dividing device 5 includes a second yarn dividing frame 51 and a second yarn dividing rod 52 arranged above the second yarn dividing frame 51 , and the second yarn dividing rod 52 protrudes upwards. The yarn 7 coming out of the drying device 4 passe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com