Composite paper and manufacturing method thereof

A production method and technology of composite paper, which are applied in special paper, chemical instruments and methods, paper, etc., can solve the problems of paper being easily wrinkled, torn or dirty, difficult to clean and affect, and to solve the problem of deformation And layering, not easy to deform, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

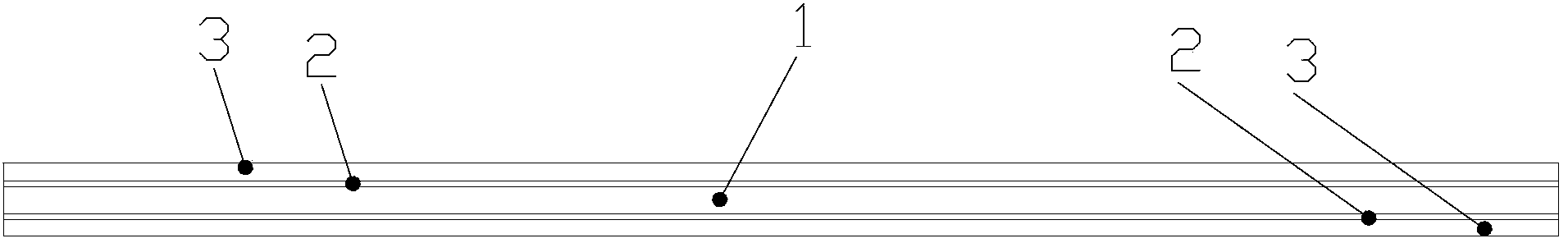

[0027] Such as figure 1 As shown, a kind of composite paper of the present invention comprises plain paper 1, and the top surface of described plain paper 1 is provided with an adhesive layer 2 and a PP film layer 3 successively from bottom to top; The bottom surface of described plain paper 1 An adhesive layer 2 and a PP film layer 3 are sequentially arranged from top to bottom. The plain paper 1 is printing paper or cardboard; the adhesive layer 2 is a water-based pressure-sensitive adhesive layer.

[0028] The composite paper of the present invention is very beautiful as a whole. If you need to print on composite paper, you can print on ordinary paper first and then install PP film on both sides of the ordinary paper. Since the water-based pressure-sensitive adhesive layer has a good transparent effect after condensation and is not easy to yellow, the pattern on the ordinary paper can be used. Clearly presented to the outside world; compared with direct printing on PP mat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com