Oil flinger with water-drop-shaped turbulent flow columns

A spoiler column and water drop type technology, which is applied in the field of gas turbine combustors, can solve the problems of uneven temperature distribution at the outlet of the oil flinger and insufficient uniformity of oil output from the injection hole, so as to improve combustion efficiency, improve outlet temperature distribution, The effect of reducing kinetic energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be further described now in conjunction with accompanying drawing:

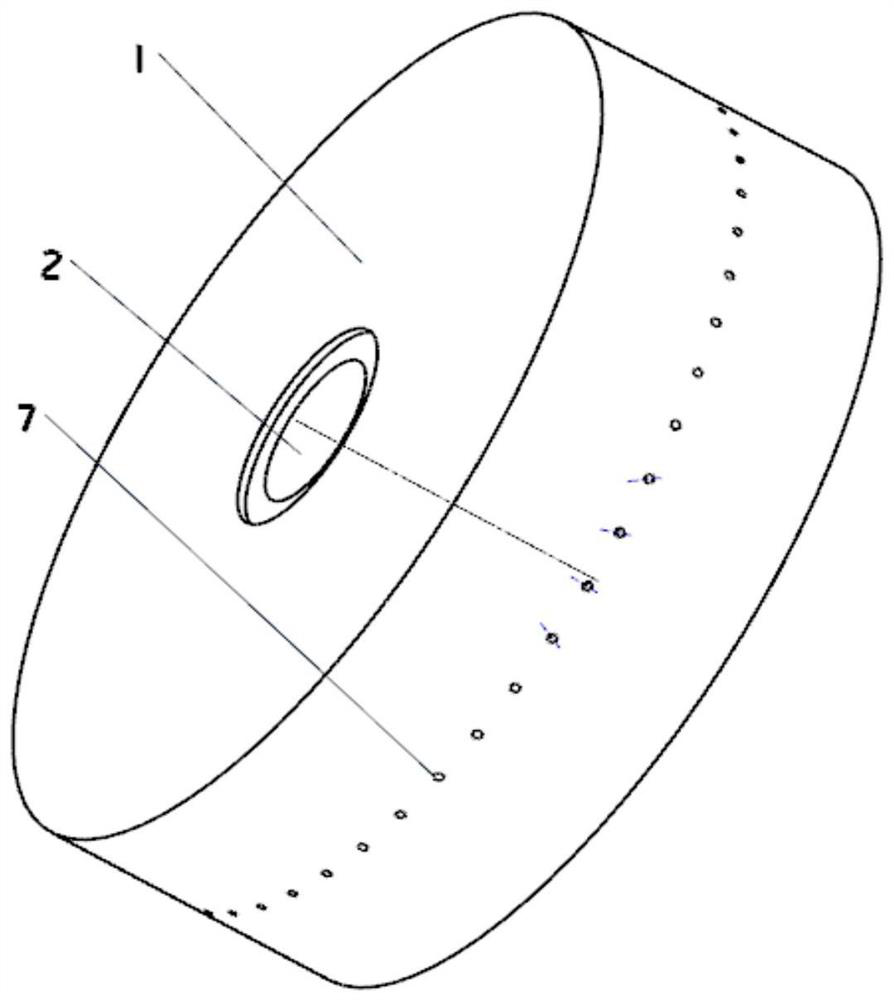

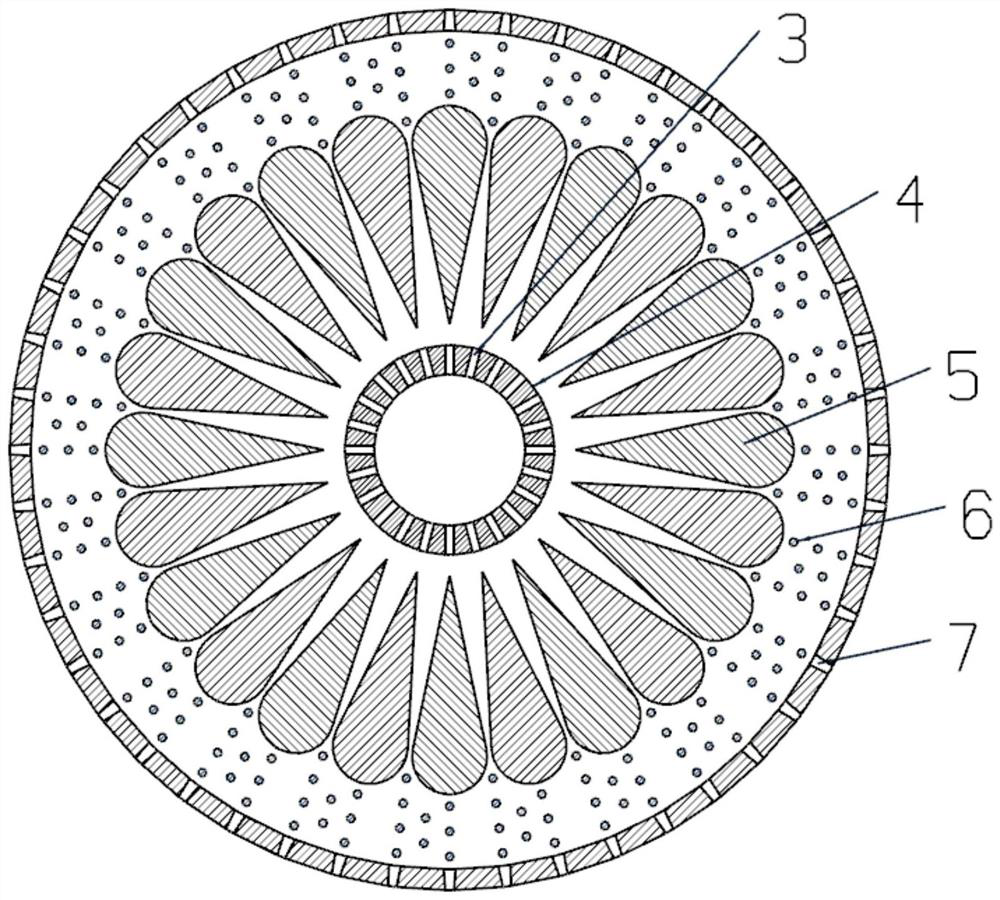

[0019] to combine figure 1 , figure 2 , the invention is an oil flinger with a droplet type spoiler.

[0020] When the oil slinger is working normally, the fuel enters the cavity of the oil slinger through the oil inlet 2, and then enters the flow equalizer 3, and the evenly arranged flow equalizer outlet 4 makes the fuel evenly distributed and enters the main cavity, facing the flow equalizer The sharp part of the head of the droplet spoiler 5 of the outlet 4. At this time, due to the high rotational speed of the oil flinger, the fuel directly collides with the sharp part of the droplet spoiler 5 at a very high speed, and the fuel block is quickly torn into pieces. In addition, the drop-shaped spoiler 5 will cause the broken fuel to collide with the ball-shaped spoiler 6 at a high speed with relatively low kinetic energy loss. The small, dense and staggered spherical sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com