Pin plate fin water pipe type general condensing boiler

A condensing boiler, water-tube technology, applied in fluid heaters, energy-saving heating/cooling, air heaters, etc., can solve the problems of difficult processing and manufacturing of heat exchange elements, and achieve enhanced heat exchange in the furnace, increased volume, The effect of increasing thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention will be described in more detail below in conjunction with the accompanying drawings.

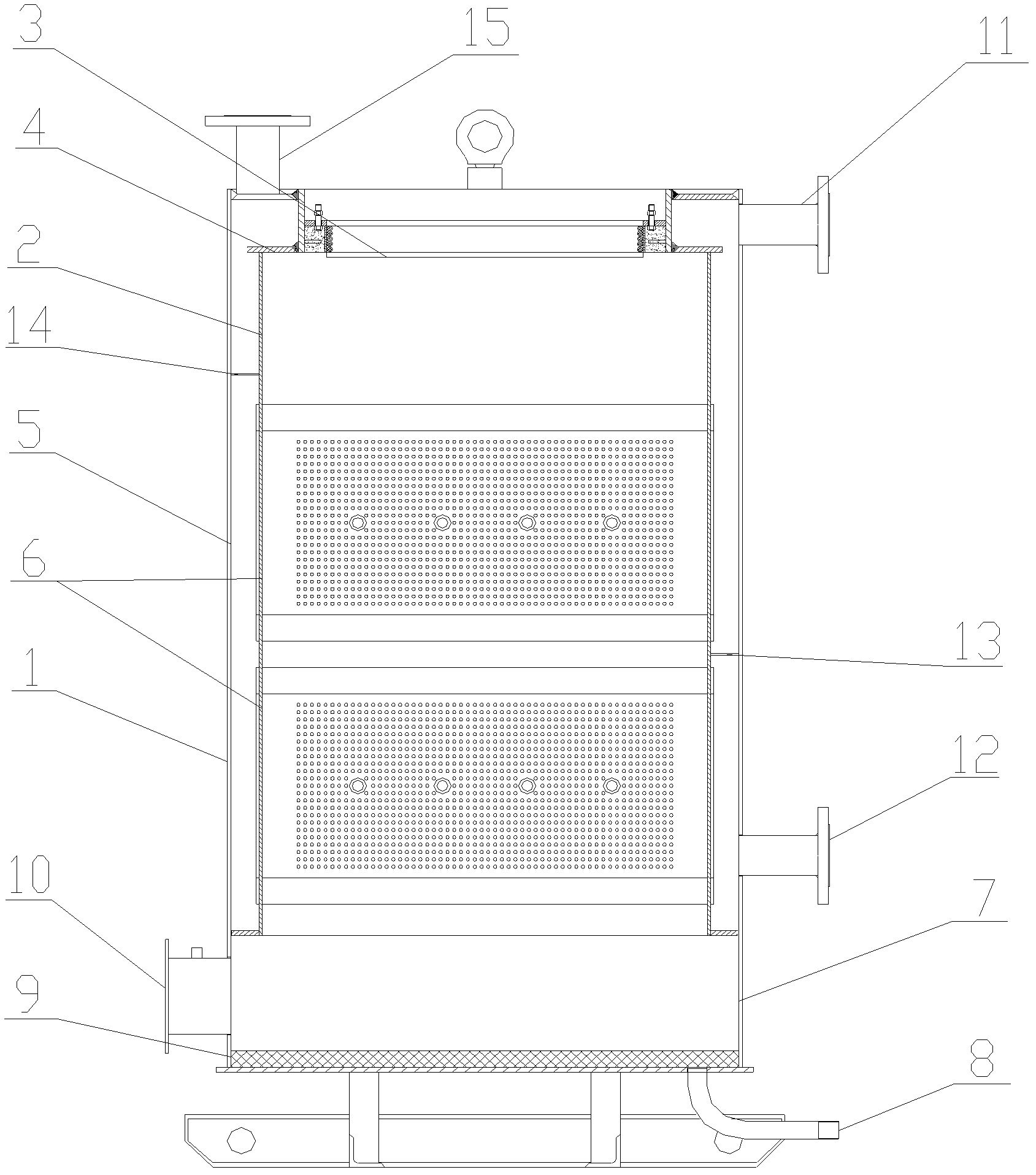

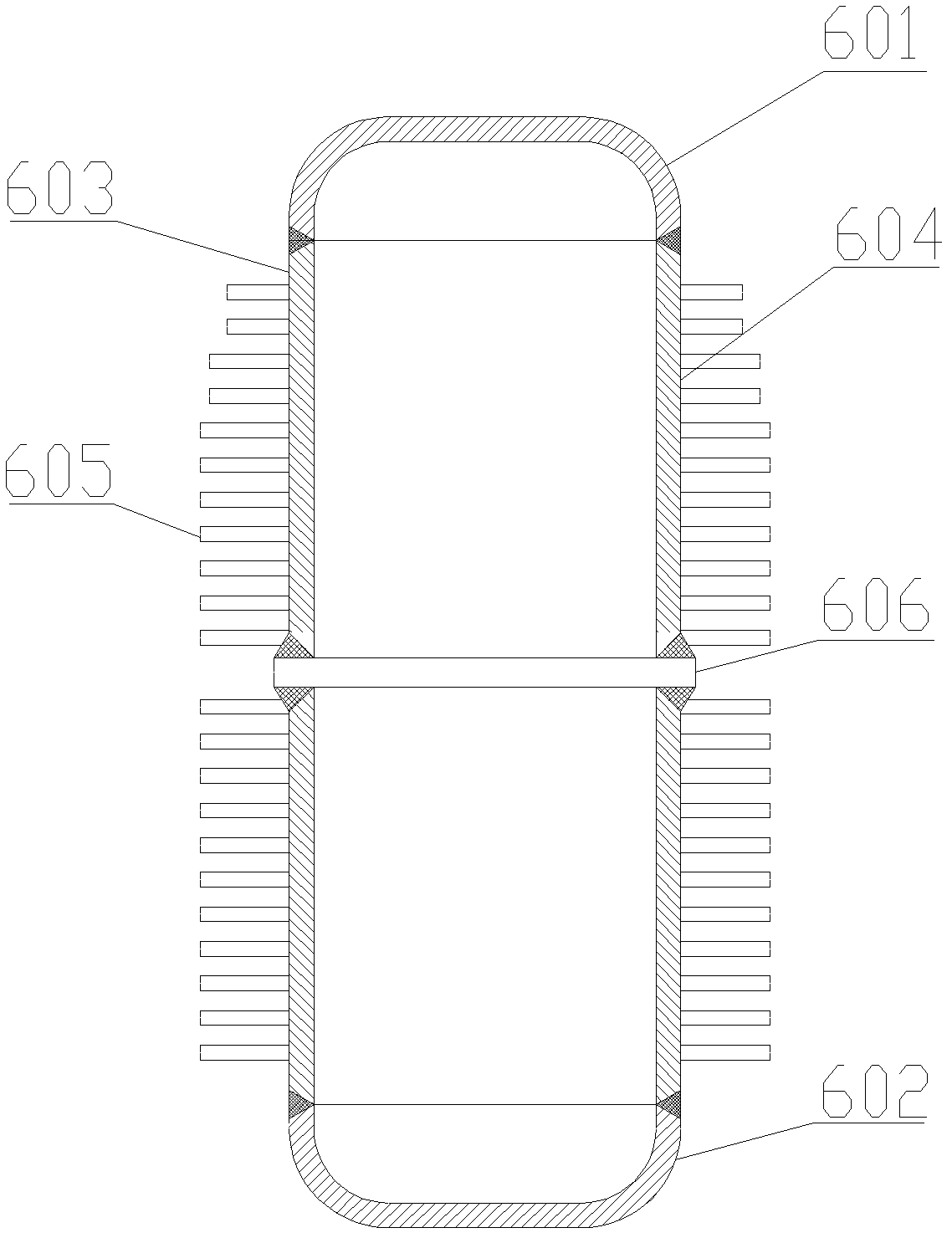

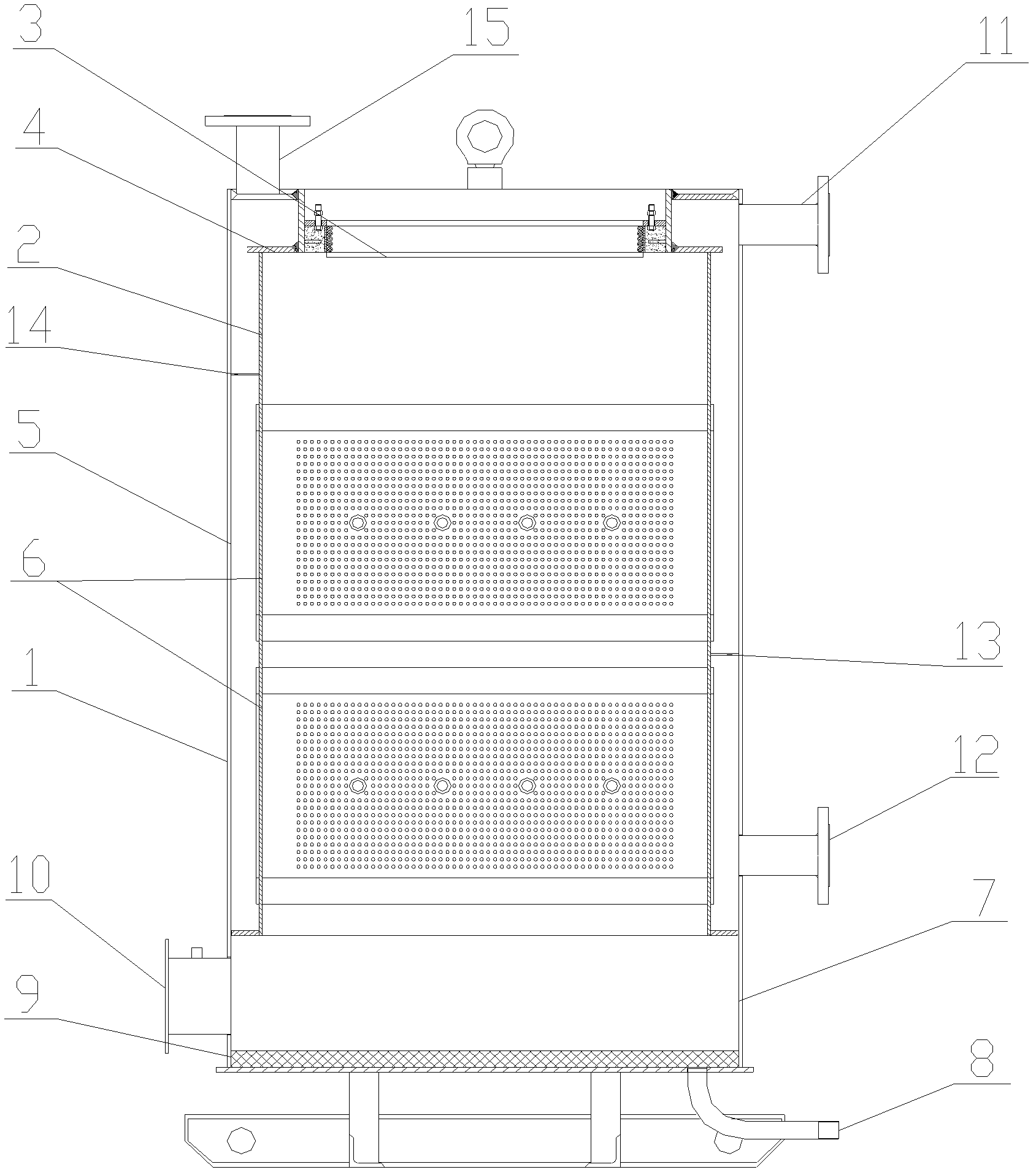

[0023] A pin-plate-fin water-tube integral condensing boiler, comprising a casing 1, a turning smoke chamber 7 is provided at the lower part of the casing 1, and a condensate neutralization treatment device 9 with a condensate discharge pipe 8 is arranged under the turning smoke chamber 7, and the whole preheating On the upper top plate 4 of the mixed flameless burner 3 boiler, below the full premixed flameless burner 3 is the furnace heat exchange space 2, and more than one overall convection and condensation heat exchange pins are arranged in the lower part of the furnace heat exchange space 2 The plate-fin water tube heat transfer element 6, the bottom of the heat exchange space 2 in the furnace is connected to the top of the turning smoke chamber 7, the inner wall of the shell 1 is connected to the outer wall surface of the heat exchange space 2 in the furnac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com