Oil inlet of common rail injector

A common rail fuel injector and fuel injector technology, which is applied in the directions of machines/engines, fuel injection devices, engine components, etc., can solve the problems of long control piston length, affecting the performance of fuel injectors, and easy instability, etc. Work stability, avoid work instability, reduce the effect of lateral impact force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

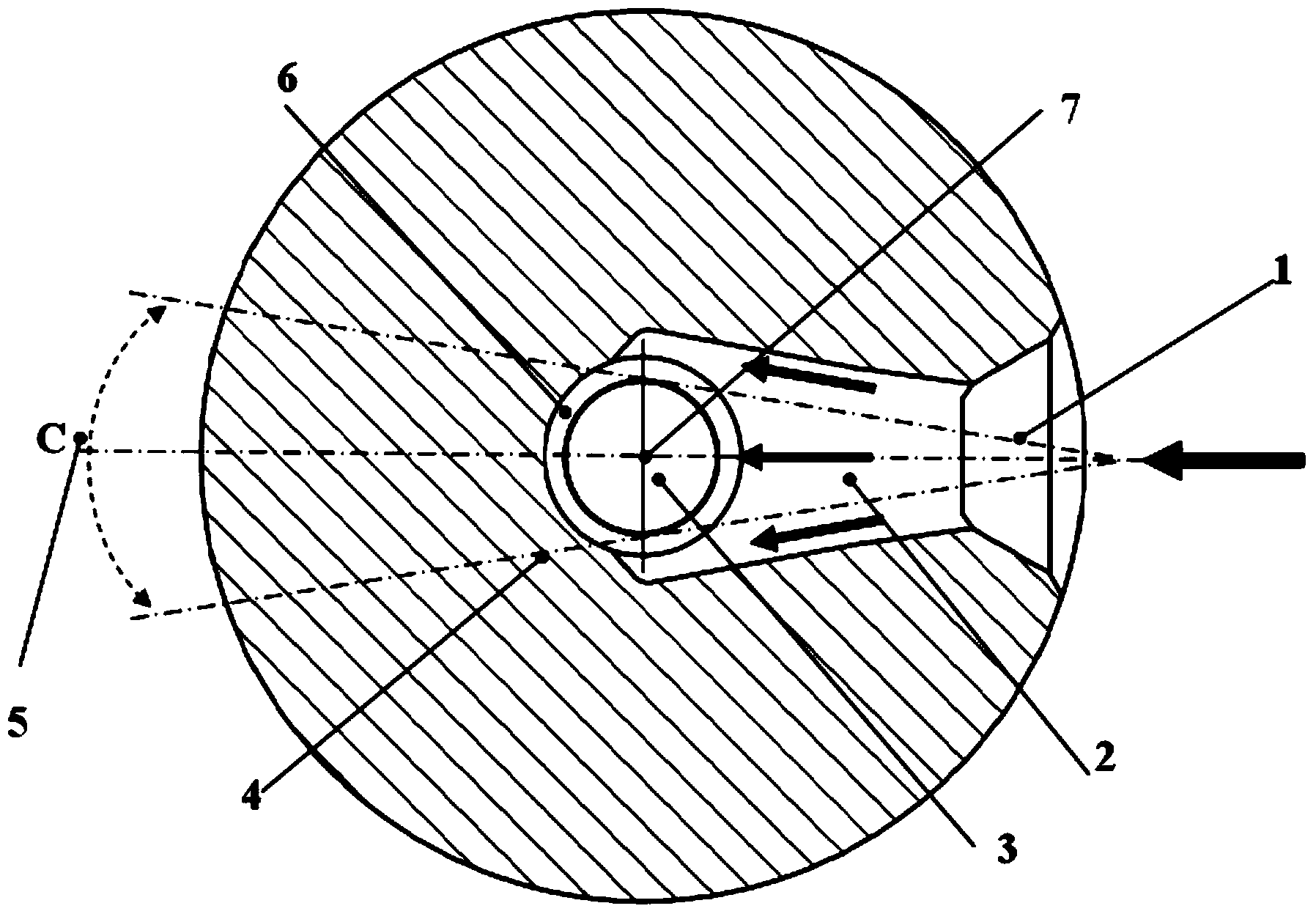

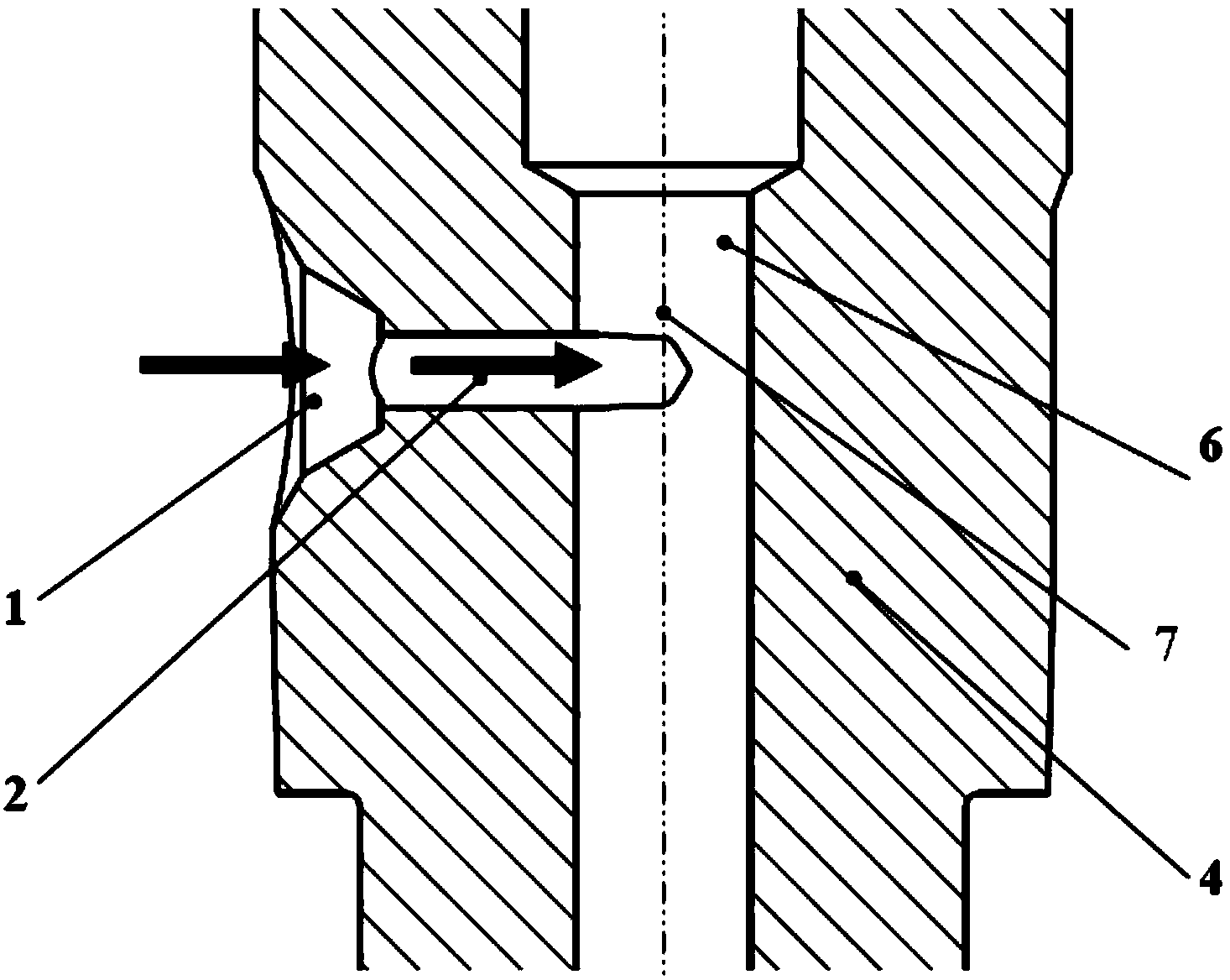

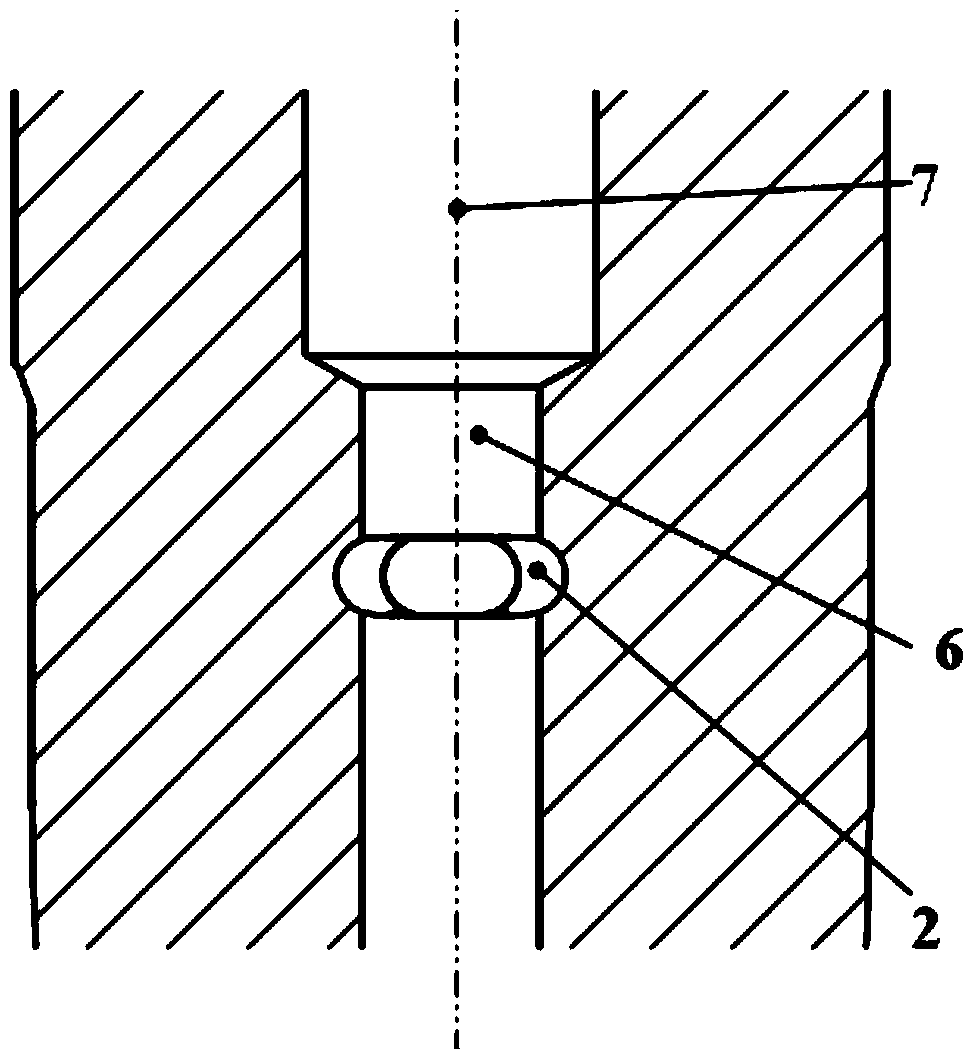

[0017] The oil inlet structure of a common rail fuel injector in the present invention can refer to the attached Figure 1~4 description of

[0018] One kind of fuel injector oil inlet is the oil passage between the oil inlet horizontal chamber and the high pressure oil chamber 6 in the fuel injector. The oil inlet of the present invention is composed of two parts of oil passages. The oil passage a 1 located on the outermost side of the injector body 4 is tapered from the fuel flow direction, and the cross-sectional shape of the oil passage a 1 is circular. The oil passage a 1 is used to connect with the oil inlet transverse cavity, and the tapered tapered structure can ensure the sealing of high-pressure fuel at the connection.

[0019] The section shape of the fuel passage b 2 inside the injector body 4 is waist-shaped, which can make more fuel flow to both sides of the control piston 3 and reduce the fuel directly flowing to the control piston 3 from the front. At the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com