Double-blade shear device of steel rolling line strip steel abutted seam laser welding machine

A laser welding machine and rolling line technology, applied in the field of double-blade shears, can solve the problems affecting seam and welding quality, unstable blade gap, blade edge wear, etc., to achieve fast and convenient adjustment, shear quality assurance, Guaranteed effect of cutting edge clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

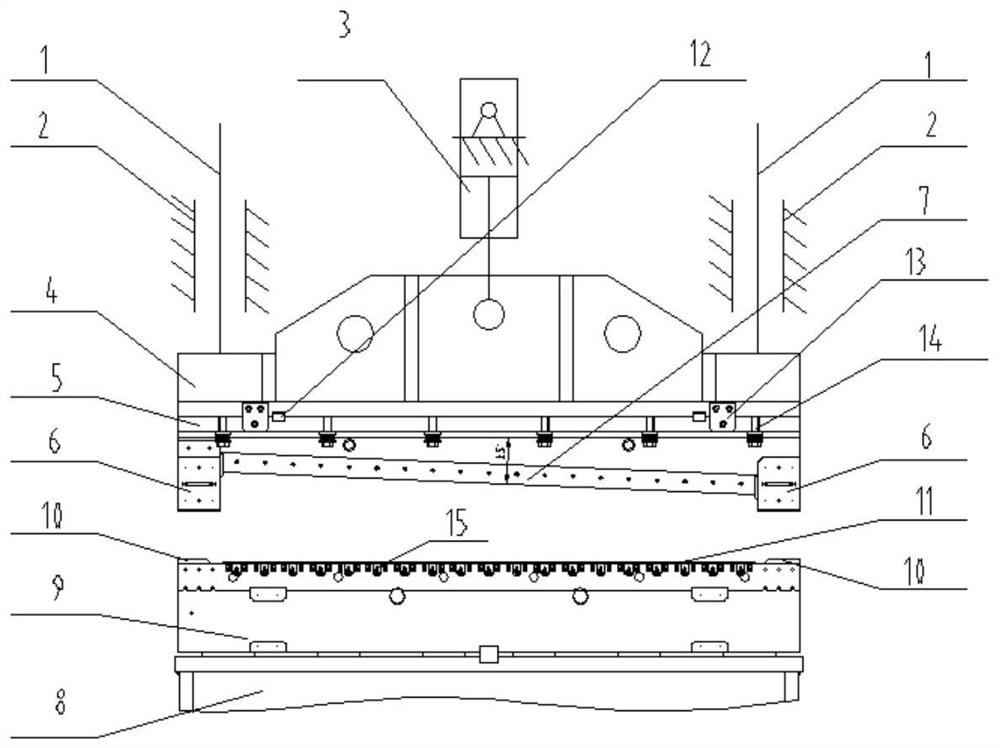

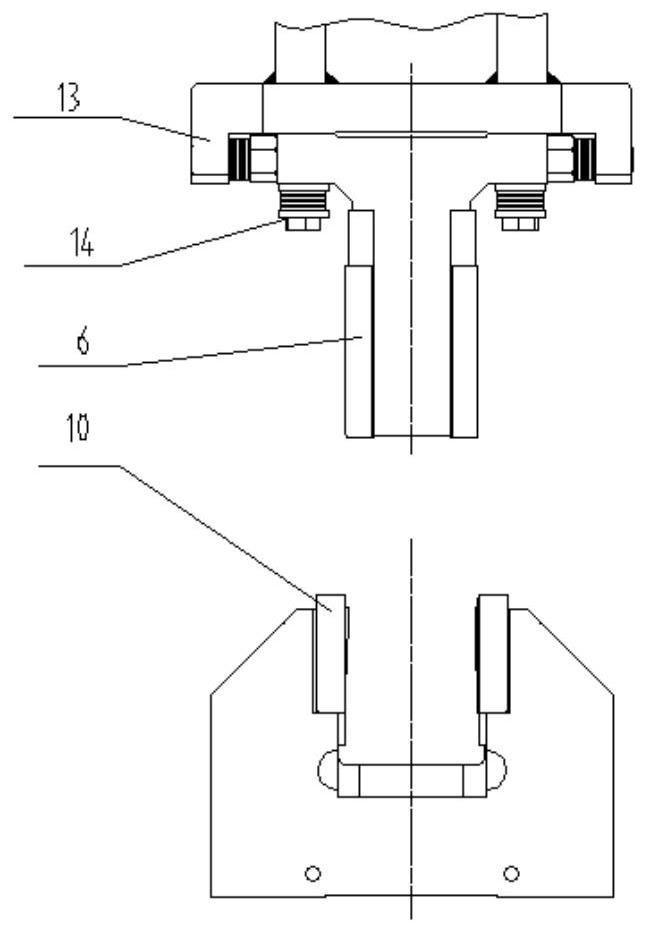

[0044] In this embodiment, the upper knife rest 5 is changed from a fixed type to a floating type, and its specific structure is that the left and right adjustment mechanisms 13 of the upper knife rest are respectively arranged on both sides of the upper knife rest 5 and the upper knife seat 4 along the width direction, It includes stoppers 16 fixed on both sides of the upper knife rest 4, the lower ends of the stoppers 16 extend to both sides of the upper knife rest 5, and a transverse step screw 17 is designed under the stopper 16, and the transverse step screw 17 passes through the stopper. The counterbore of block 16 outsides and disc spring group 18 are locked on the nut 19, and disc spring group 18 is installed in the counterbore of block 16 inboards, and nut 19 contacts the side of upper knife rest 5. The vertical limit mechanism 14 of the upper knife rest includes a vertical adjustment screw, which passes through the opening slot of the upper knife rest 5 and is locked ...

Embodiment 2

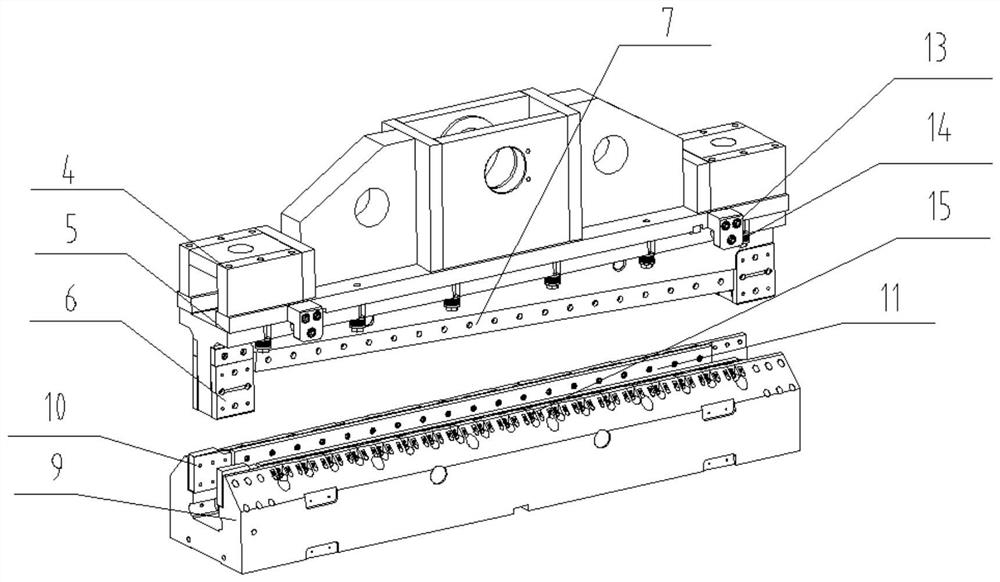

[0048] Embodiment 2 is a further optimization scheme based on Embodiment 1. A cutting edge gap adjustment mechanism is designed between the lower blade 11 and the lower tool holder 9, and an adjustment mechanism is arranged at each blade fixing screw. Such as Figure 5-10 As shown, with this mechanism, the cutting edge clearance at each locking screw can be freely adjusted. Equally, also be 2 ° of angles between two lower blades 11, promptly be " eight " shape, this design is to avoid the cutting edge of upper blade 7 from scratching the outside of lower blade 11, helps the blanking of cutting waste material simultaneously. Its cutting edge gap adjustment mechanism includes a plurality of sets of adjusting inclined blocks 22 arranged on the inner side of the lower blade 11 along the length direction of the lower blade 11, and the side of the adjusting inclined blocks 22 close to the lower blade 11 is a slope, The other side opposite to it is a vertical surface, and the adjust...

Embodiment 3

[0053] Embodiment 3 is a further optimization scheme based on Embodiment 2. The original right angle of the belt relief groove 28 is improved to a rounded corner, so that when the lower knife rest 9 is subjected to shear force, the lateral deformation is smaller, and the belt groove is stressed. More reasonable, make lower knife rest 9 not easily deformed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com