Pilot valve and four-way valve

A pilot valve and conduit technology, applied in multi-port valves, valve details, valve devices, etc., can solve the problems of unreliable filter connection and high manufacturing cost, and achieve the effects of small size, reduced production cost, and improved connection strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

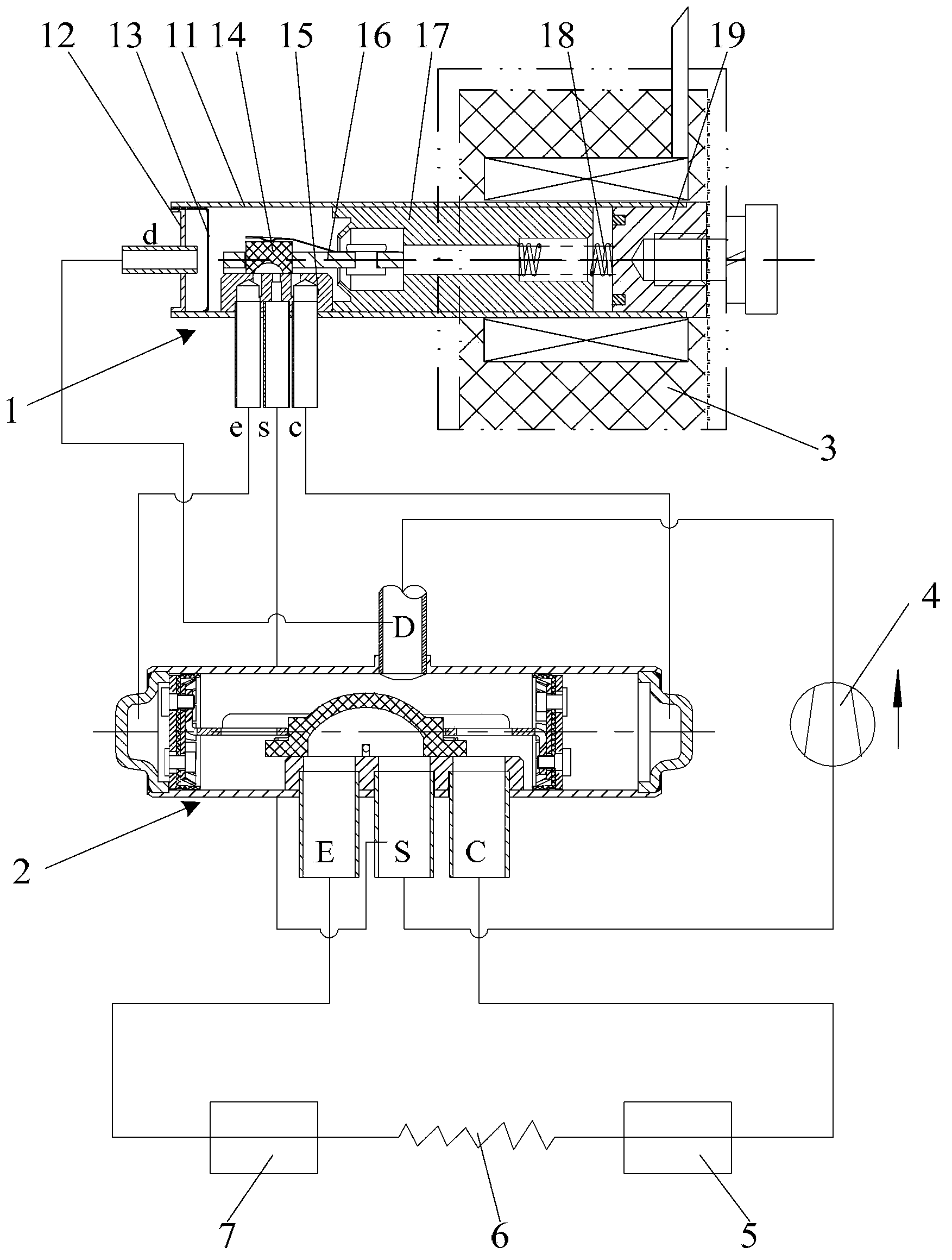

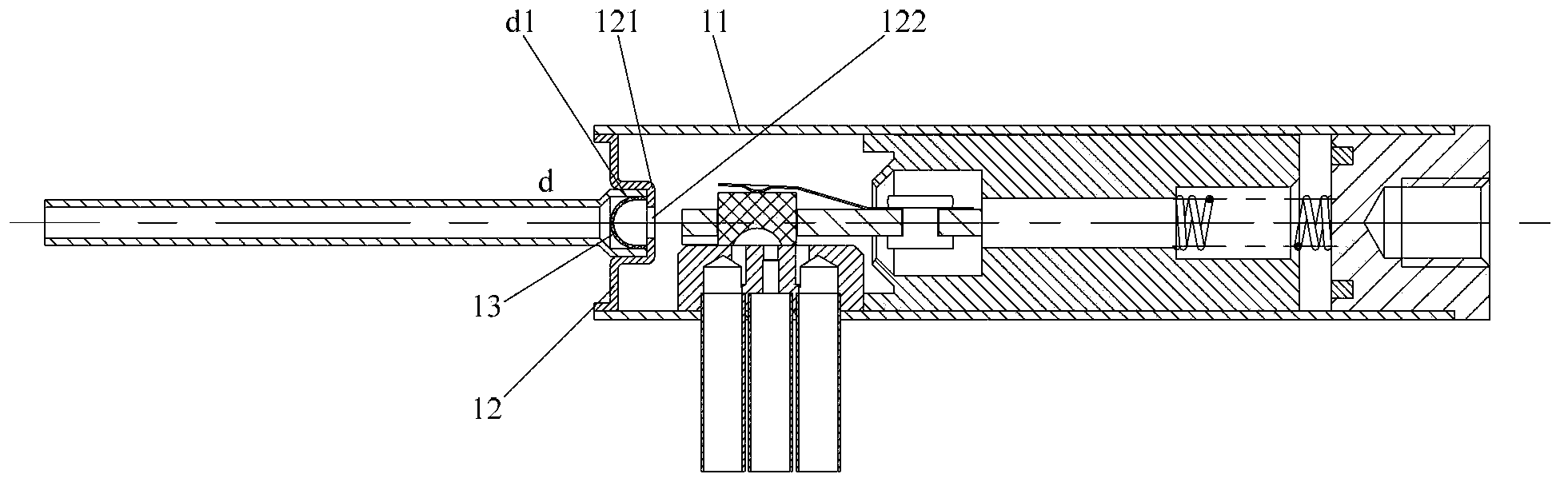

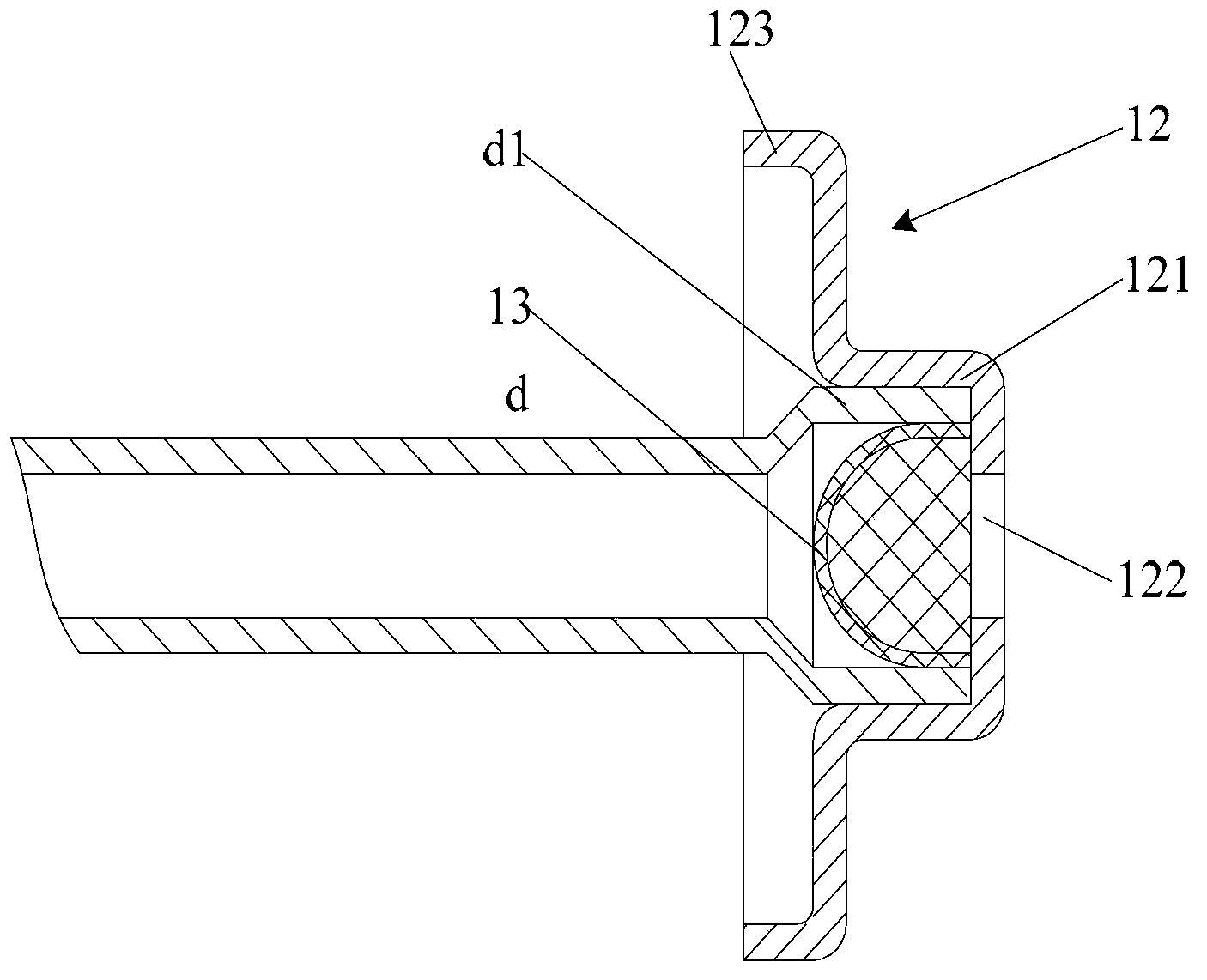

[0022] figure 2 Schematic diagram of the structure of the pilot valve provided for the embodiment of the present invention; image 3 figure 2 A partial schematic diagram of the pilot valve in .

[0023] Such as figure 2 and 3 As shown, a pilot valve 1 provided in this embodiment includes a conduit 11 , a filter 13 , an end cap 12 and a capillary d.

[0024] The filter 13 includes a cap-shaped filter net. One end of the capillary d has a filter accommodation part d1, and the filter 13 is clamped in the filter accommodation part d1. The diameter of the filter accommodation part d1 is larger than the diameter of the main pipeline of the capillary .

[0025] The end cap 12 has a flange 123 facing the outside of the conduit 11. The flange of the end cap 12 is fixedly connected to the inner wall of one end of the conduit 11. The end cap 12 has a support portion 121 for blocking the filter 13, and the filter accommodating portion d1 cooperates with the supporting part 121, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com