Cement rotary kiln tertiary air duct high temperature gate valve valve opening feedback device

A valve opening feedback and cement rotary kiln technology, which is applied to valve devices, engine components, mechanical equipment, etc., can solve problems such as inability to perform remote control, and achieve low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

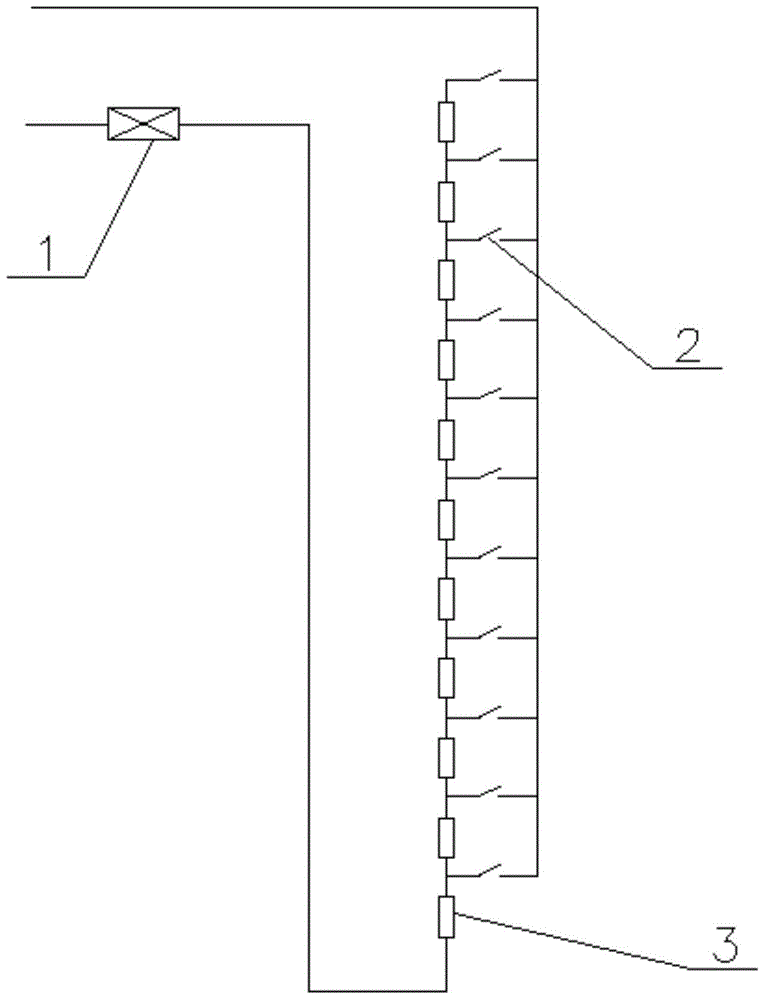

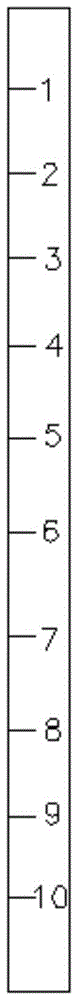

[0009] Such as figure 1 and figure 2 As shown, the feedback device for the valve opening of the high-temperature gate valve of the cement rotary kiln tertiary air duct in this embodiment includes a stainless steel shell and a magnet, and a scale line for the valve opening is set on the metal shell. It includes a temperature transmitter 1 with a graduation number of PT100, 11 series resistors 3 and 11 reed switches 2, the first resistance value of the 11 series resistors 3 matches the range of the temperature transmitter, One end of temperature transmitter 1 with graduation number PT100 is connected to 24V DC power supply, the other end of temperature transmitter 1 is connected to one end of the first resistor of 11 series resistors 3, and every two resistors 3 are connected in series The point is connected to one end of a reed switch 2, the other end of the last resistor is connected to one end of the last reed switch 2, the other end of 11 reed switches 2 is connected to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com