LED filament strip, LED filament lamp and method for manufacturing core filament of LED filament lamp

An LED filament lamp and LED filament technology, applied in the field of lighting, can solve the problems of many welding human factors, affecting product quality, and low production efficiency, and achieve high promotion and application value, good product consistency, and high production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

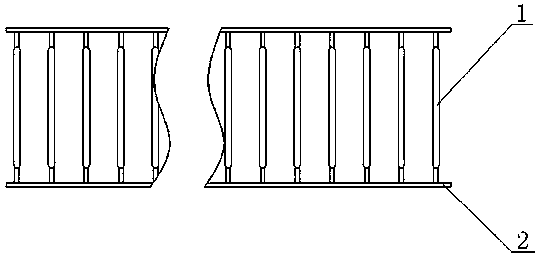

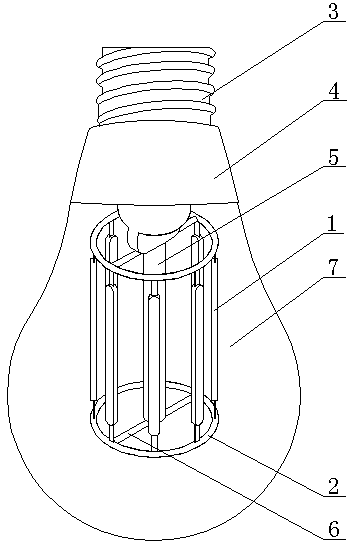

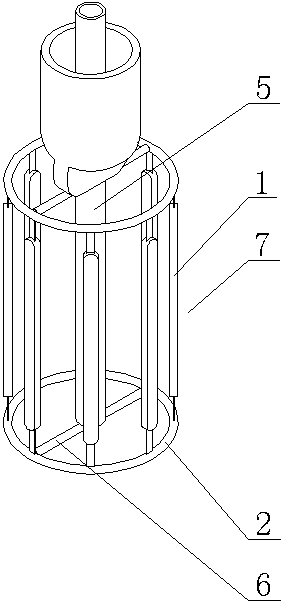

[0028] exist figure 1 , figure 2 and image 3 Among them, an LED filament ribbon includes an LED filament 1, the two ends of the LED filament 1 are electrical connection points, the LED filaments 1 are arranged in a strip shape, the LED filaments 1 are arranged in parallel, and the intervals are equal, and the two ends of the LED filament 1 are electrically connected. The connection points are connected with wires 2, and the wires 2 at the electrical connection points at both ends of the LED filament 1 are strips of tinfoil. The LED lamp ribbon adopts a braiding machine to realize its manufacture, and the production efficiency is high.

[0029] exist figure 1 , figure 2 and image 3 Among them, the LED filament lamp made of the LED filament ribbon of the above embodiment includes a lampshade, a lamp cap 3, a lamp holder 4, an LED filament ribbon 7 and a stem 5, the stem 5 includes an exhaust pipe and a trumpet pipe, and the exhaust pipe wears Through the trumpet tube, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com