Continuous molten metal film generating device and method under high-intensity magnetic field

A membrane generation and metal liquid technology, which is applied in the fields of climate sustainability, nuclear reactors, nuclear power generation, etc., can solve the problems of increased flow resistance, large driving energy consumption, large size, etc., and achieve the effect of reducing electromagnetic resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

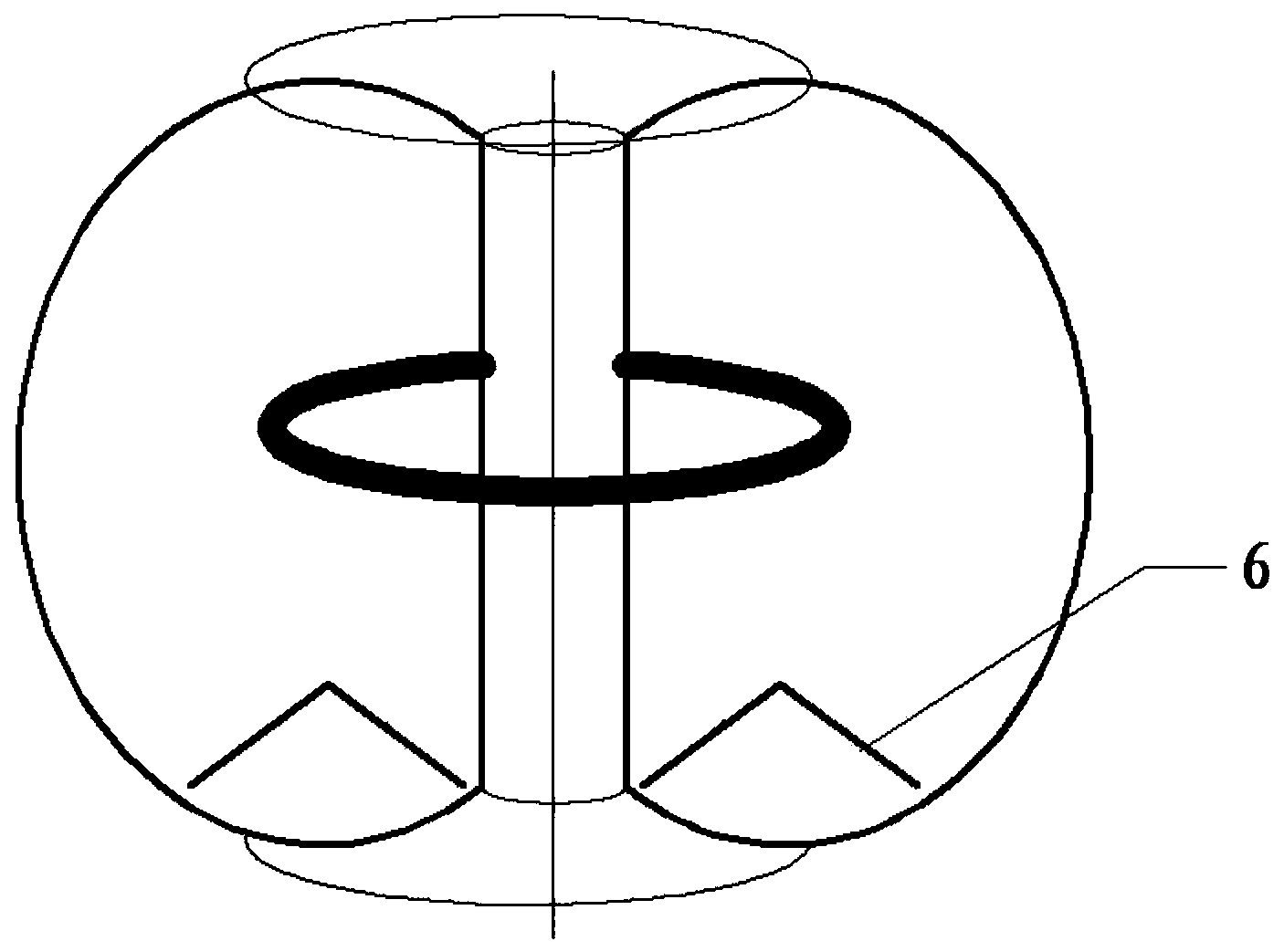

[0038] In this embodiment, the International Thermonuclear Experimental Reactor device (ITER) is a kind of magnetic confinement tokamak device, and its main parameters are shown in Table 1. The liquid lithium wall can be realized by using the present invention.

[0039] Table 1 Basic parameters of ITER device

[0040]

[0041]

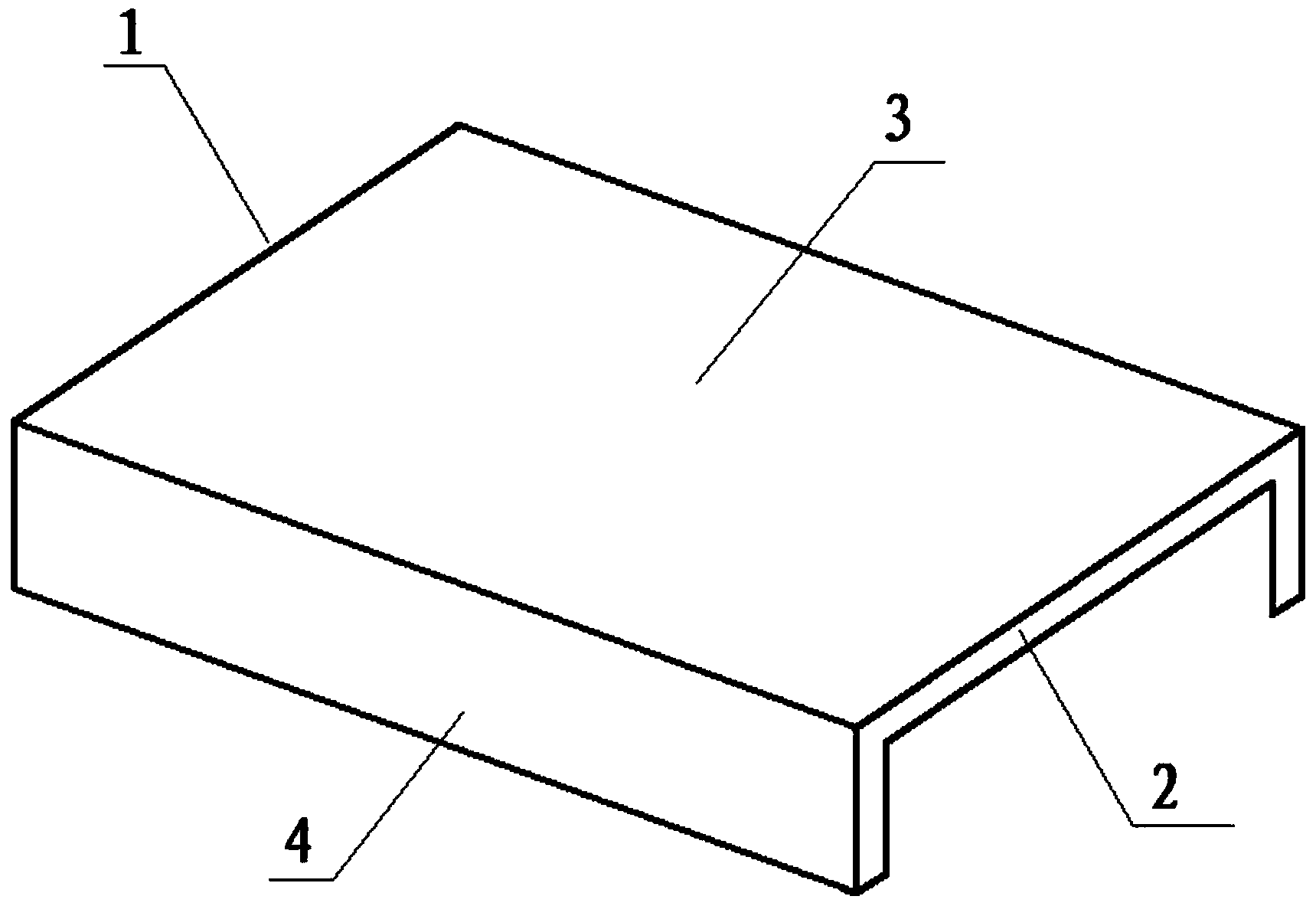

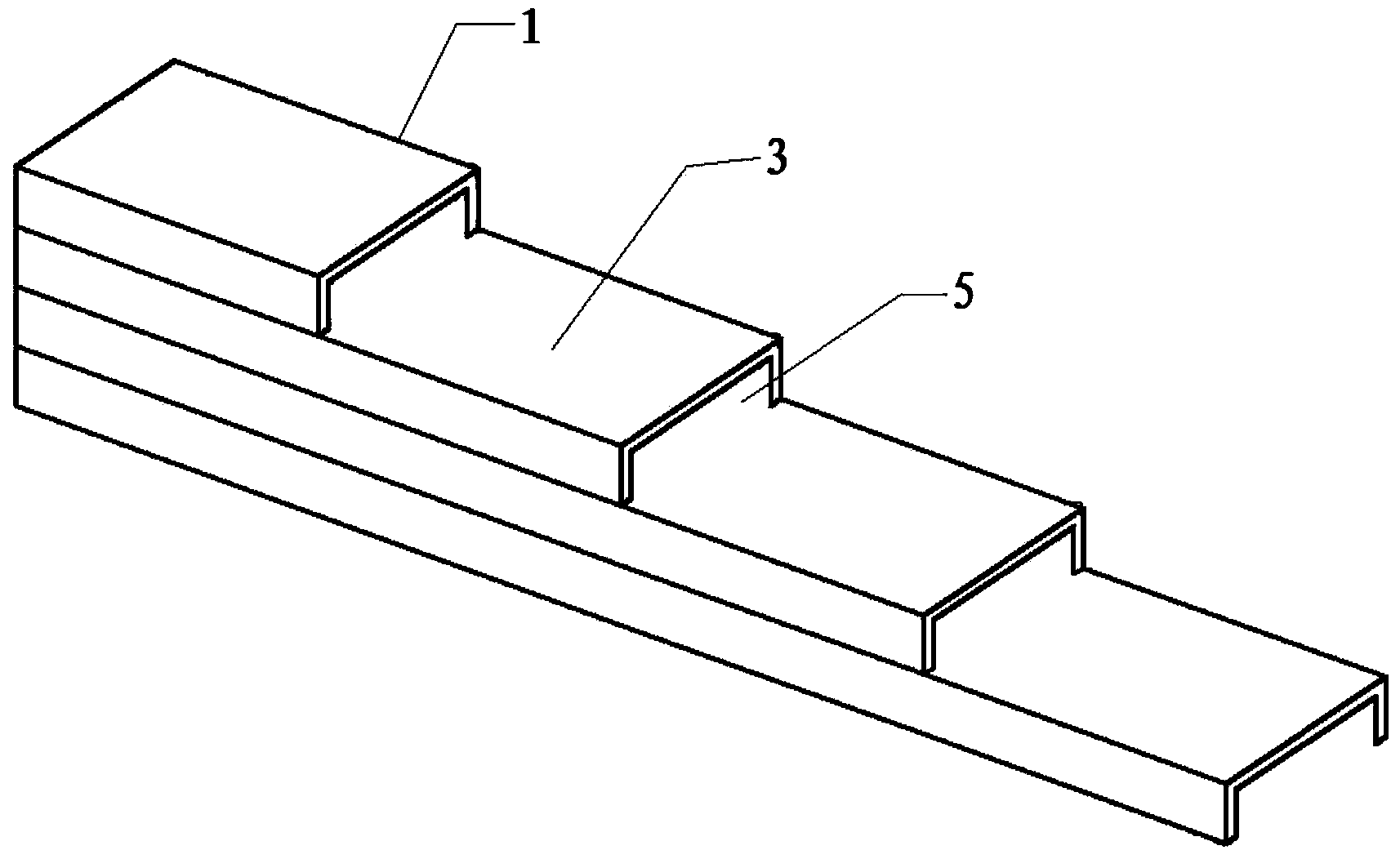

[0042] In this embodiment, the magnetic confinement nuclear fusion device is a typical nuclear fusion experimental reactor under construction. The required liquid divertor is formed by stacking multiple liquid film generation subunits 1, and the number of small units used for continuous liquid film generation is determined to be 10 according to the geometric parameters in Table 1, from the uppermost layer to the lowermost layer of liquid film generation The lengths of the small units are 5cm, 10cm, 15cm, 20cm, 25cm, 30cm, 35cm, 40cm, 45cm and 50cm. The length of the output channel 5 in each layer is not equal, but the length of the free liquid met...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com