Connector with wire cover

A technology for connectors and wires, applied in the field of connectors with wire covers, can solve problems such as poor assembly characteristics and inability to easily assemble wire covers, and achieve the effect of improving versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

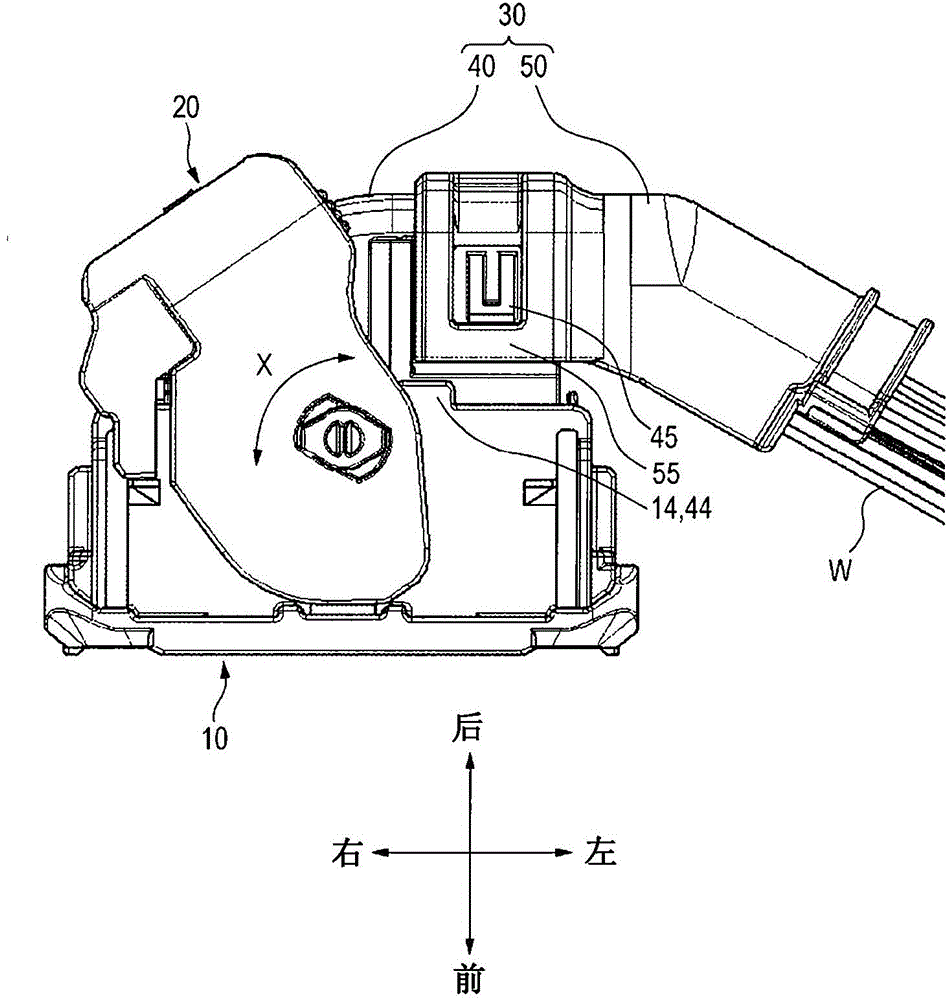

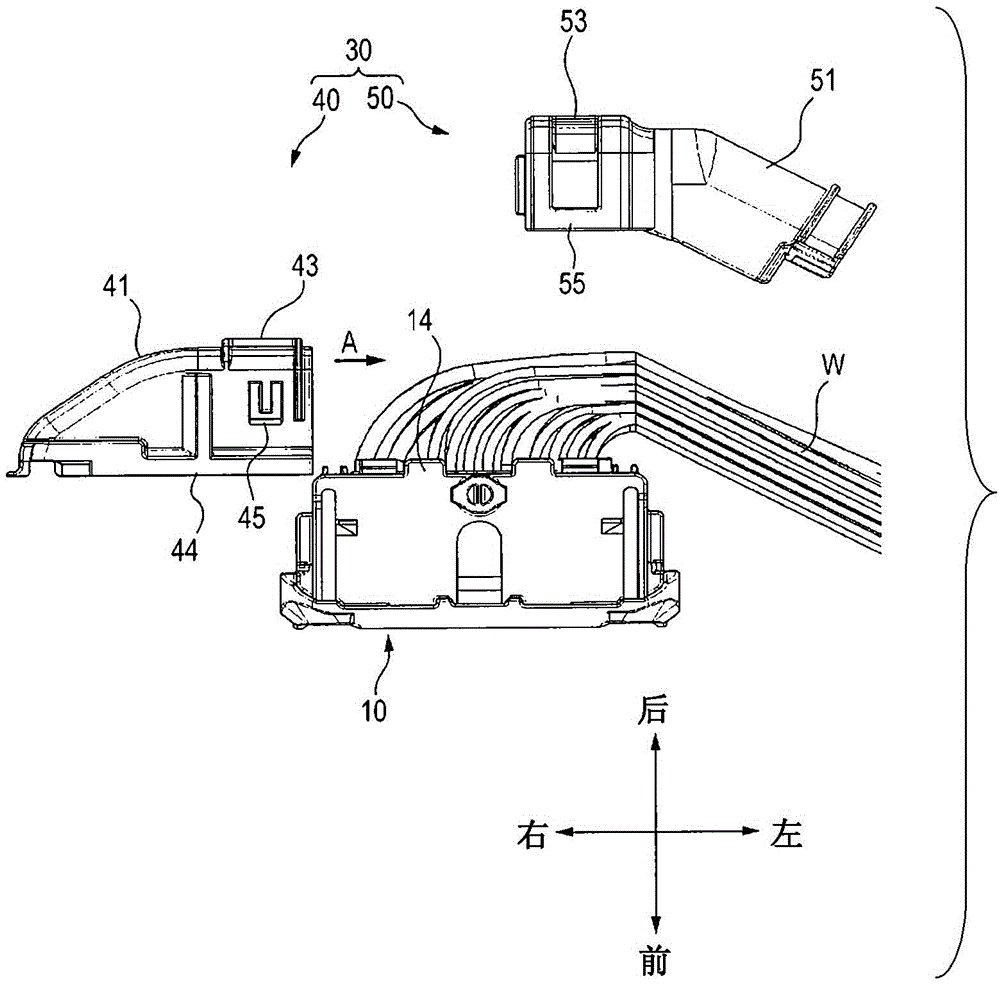

[0041] Embodiments of the present invention will be described below with reference to the drawings.

[0042] In the following description, it is assumed that the side where the connector with a wire cover of this embodiment is fitted to the mating connector is the front side, the side opposite to the front side is assumed to be the rear side, and a large number of terminals ( (not shown in the drawings) are aligned in the right-left direction or the left-right direction.

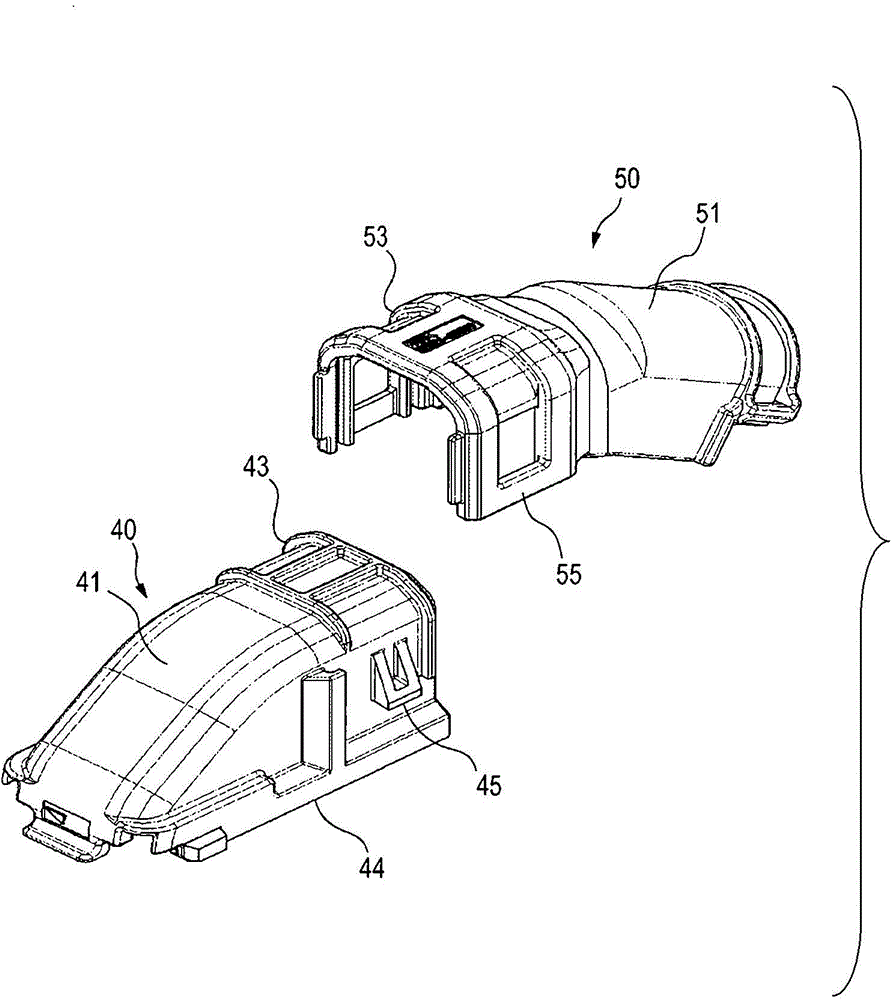

[0043] Such as figure 1As shown, the connector with a wire cover of this embodiment includes: a connector body 10 , a wire cover 30 and a lever 20 . The wires W are led out from the rear of the connector body 10 rearward. The wire cover 30 is attached to the rear portion of the connector body 10, and after the wire is bent once toward one side (the left side opposite to the side to which the lever 20 to be described below is attached), it will be released from the connector body. The wire W drawn out from...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com