A greening device in a chrysanthemum greening machine

A technology of a greening device and a greening machine, which is applied in the direction of tea substitutes, etc., can solve the problems of no structural design of the greening device, low steam utilization rate, reduced work efficiency, etc., and achieves reasonable structural design, wide application and improved work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

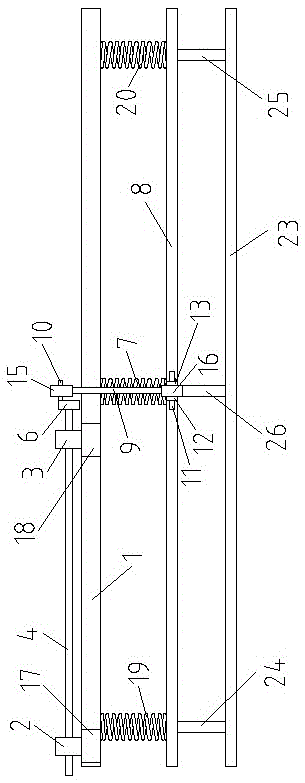

[0022] The present invention will be further described in detail below in conjunction with the accompanying drawings and examples. The following examples are explanations of the present invention and the present invention is not limited to the following examples.

[0023] Example.

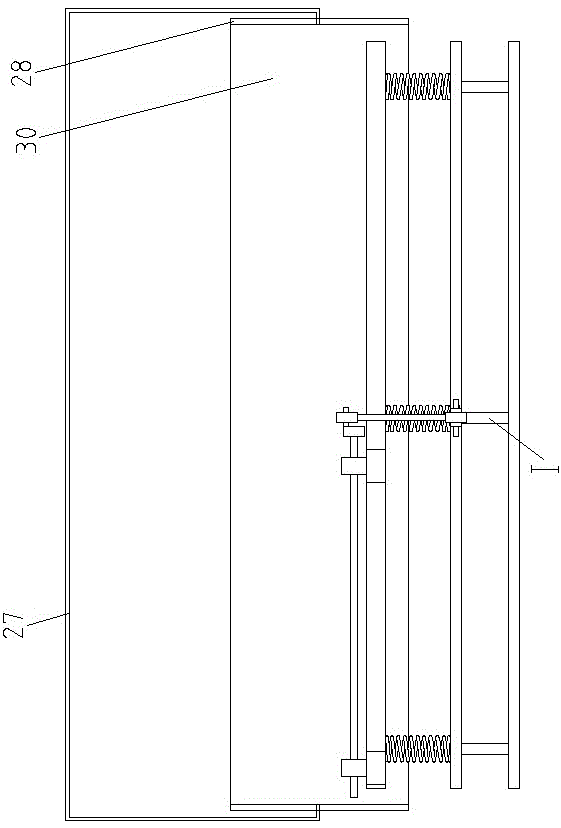

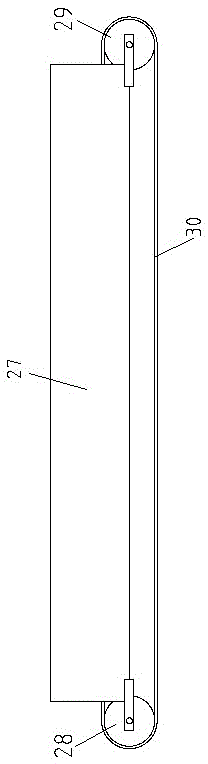

[0024] see Figure 1 to Figure 8 , the de-enzyme device in the present embodiment chrysanthemum de-enzyme machine comprises frame, vibration discharging device I, de-enzyme chamber 27, driving roller 28, driven roller 29 and conveyer belt 30, wherein, de-enzyme chamber 27 is fixed on the frame .

[0025] The driving roller 28 and the driven roller 29 among the present embodiment are all installed on the frame, and the driving roller 28 and the driven roller 29 are respectively positioned at the rear end of the finishing steam chamber 27 and the front end of the finishing steam chamber 27, and the driving roller 28 and the The driven rollers 29 are all rotatable freely. The conveyor belt 30 in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com