Electronic cigarette allowing liquid to be injected from top and heating assembly to be replaced at bottom

A technology of heating components and electronic cigarettes, applied in the field of electronic cigarettes, can solve the problems of poor taste, waste of e-liquid, and leakage of e-liquid to pollute the outside world, and achieve the effect of choosing good taste and improving taste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

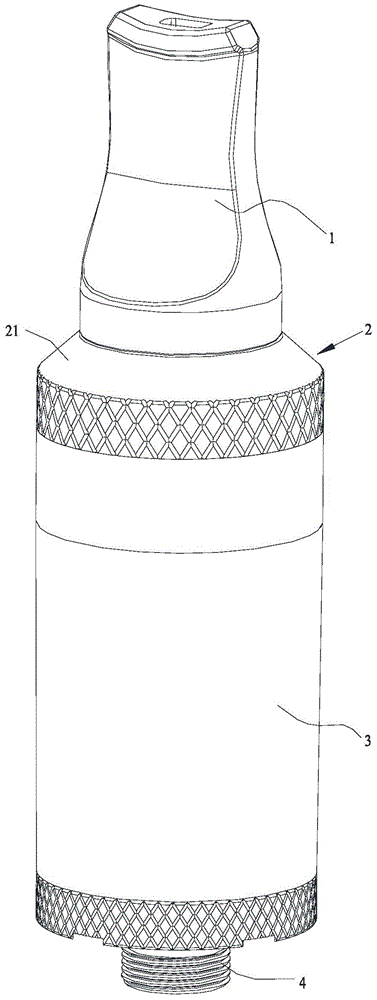

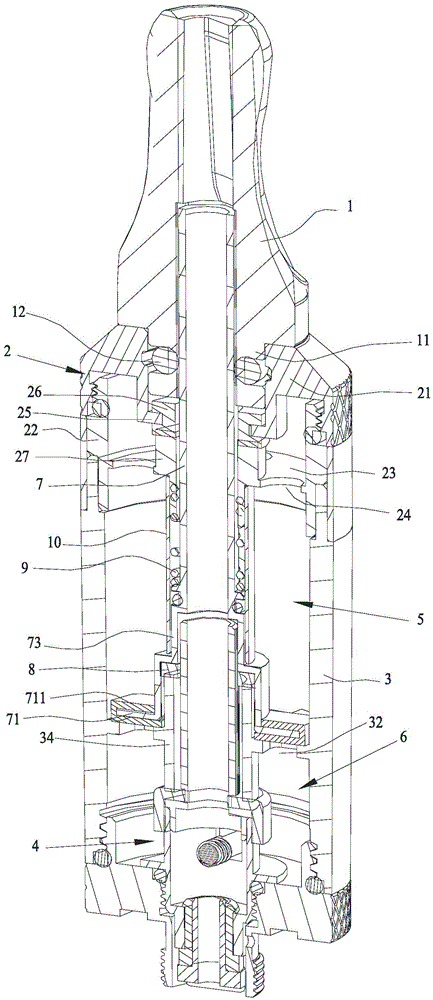

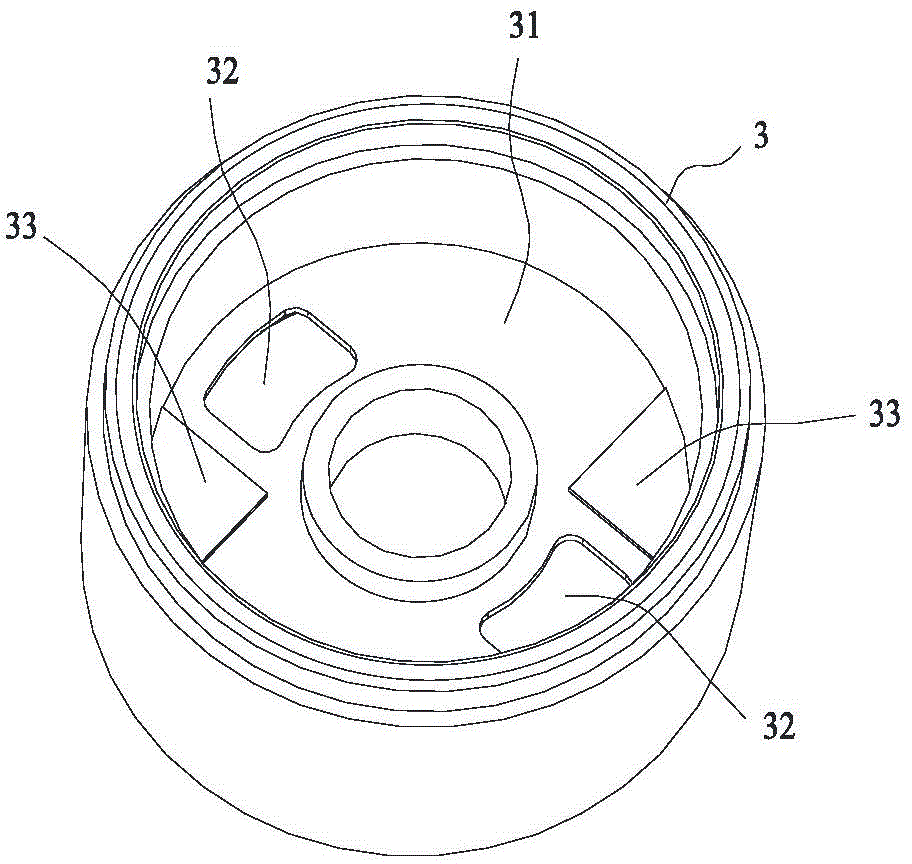

[0026] Such as Figure 1~2 The shown electronic cigarette with top liquid injection and bottom replacement heating element includes cigarette holder 1, connection assembly 2, liquid storage pipe 3 and heating assembly 4 connected in sequence from top to bottom, and connection assembly 2 is connected to cigarette holder 1 and liquid storage pipe 3 respectively. connection, the heating element 4 is detachably connected to the lower end of the liquid storage tube 3, such as image 3 As shown, the liquid storage tube 3 is provided with a partition 31, and the partition 31 divides the inner chamber of the liquid storage tube 3 into an upper chamber 5 and a lower chamber 6, and the partition 31 is provided with a liquid discharge hole 32, A rotatable atomizing tube 7 is installed above the partition 31, the lower end of the atomizing tube 7 extends radially with a stopper 71 for blocking the liquid discharge hole 32, and the upper end of the atomizing tube 7 passes through the conne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com