Roller and rolling device thereof

A technology of roller and roller surface, which is applied in the direction of grain processing, etc., can solve the problem of low first-time yield and achieve the effect of improving first-time yield, service life and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

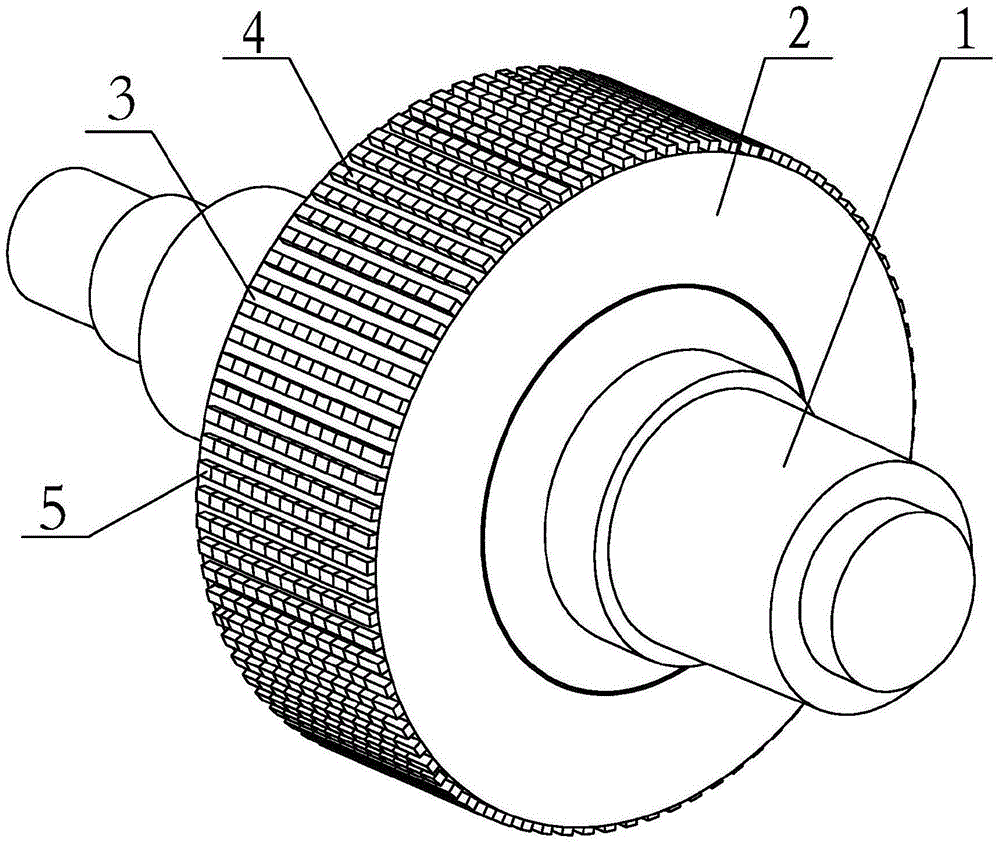

[0025] Such as figure 1 The shown roller includes a roller shaft 1 and a base body 2, on which a rib 4 is arranged, and the rib 4 is continuously formed by closely arranged protrusions 5 along the axial direction of the roller. In addition, the The bump 5 is made of high wear-resistant material. This roller is used in rolling equipment such as roller presses and vertical mills.

[0026] With the roller of this embodiment, the first-time yield is increased to 22%, the service life is increased to 15,000 hours, and the wear amount is reduced to 2.5mm after 2,100 hours of use.

Embodiment 2

[0028] Such as figure 1 The shown roller includes a roller shaft 1 and a base body 2, on which a rib 4 is arranged, and the rib 4 is continuously formed by closely arranged protrusions 5 along the axial direction of the roller. In addition, the The bump 5 is made of high wear-resistant hard alloy, and the height L1 of the bump 5 above the roller surface 3 is 7mm.

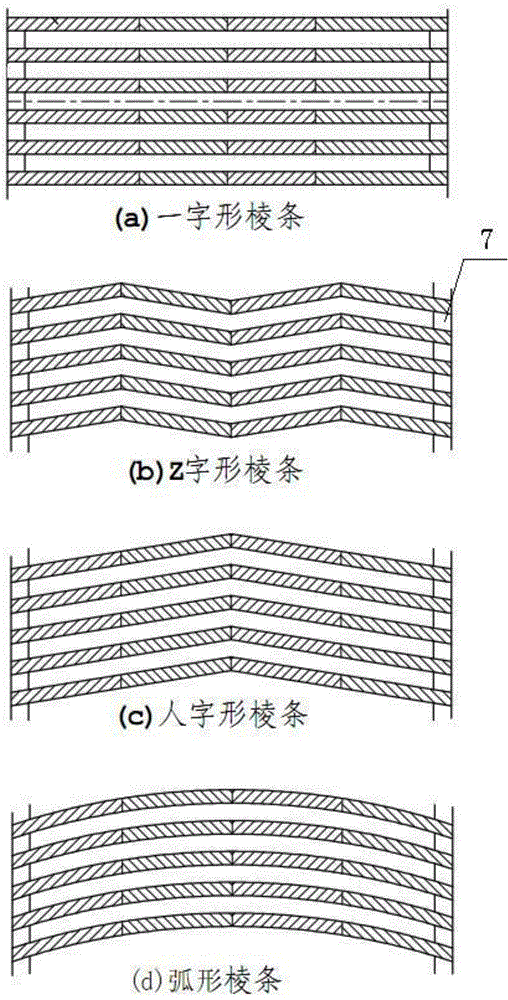

[0029] In addition if image 3 The projections 5 forming the same rib 4 shown have the same height above the roll surface 3 . This roller is used in rolling equipment such as roller presses and vertical mills.

[0030] With the roller of this embodiment, the first-time yield is increased to 25%, the service life is increased to 16,500 hours, and the wear amount is reduced to 2.5mm after 2,100 hours of use.

Embodiment 3

[0032] Such as figure 1 The shown roller includes a roller shaft 1 and a base body 2, on which a rib 4 is arranged, and the rib 4 is continuously formed by closely arranged protrusions 5 along the axial direction of the roller. In addition, the The bump 5 is made of high wear-resistant hard alloy. The bump 5 is connected to the base 2 through a groove 6 provided on the base 2, and the bump 5 is located in the groove 6 by being embedded.

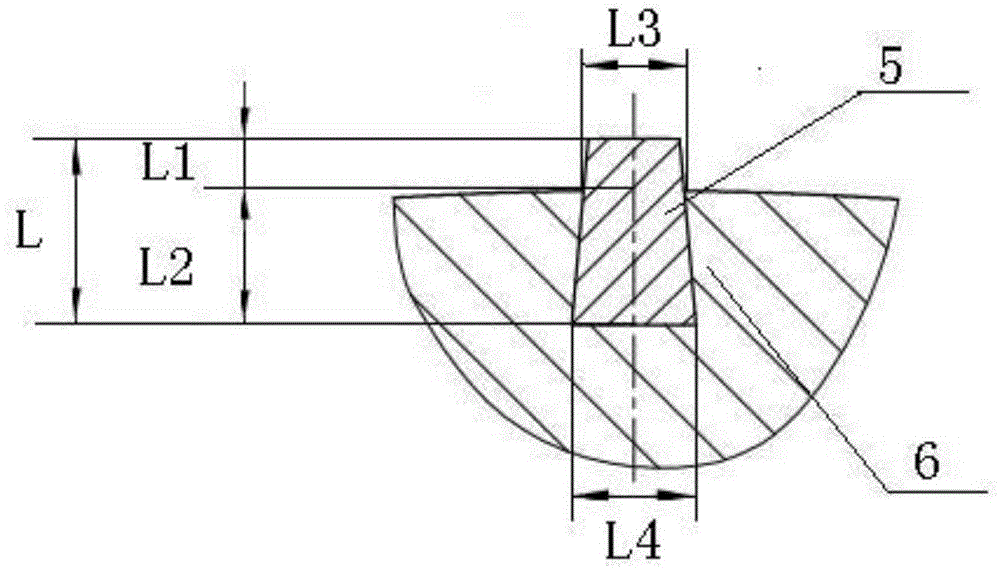

[0033] Such as figure 2 As shown, the width L4 of the bottom surface of the bump 5 is not less than the width L3 of the intersecting surface of the bump and the roller surface 3, the height L1 of the bump 5 above the roller surface 3 is 7 mm, and the overall height L of the bump 5 is 47 mm.

[0034] In addition if image 3 The shown bumps 5 forming the same rib 4 are at the same height above the roll surface 3 , and the bumps 5 are arranged on the roll surface 3 to form a straight rib 4 . This roller is used in rolling equipment such as...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com