Plant fiber molding cup cover with anti-loosening inner protruded strips and method for manufacturing inner protruded strips

A plant fiber and manufacturing method technology, applied in the direction of mechanical processing/deformation, drinking utensils, etc., can solve the problems of difficult demoulding, difficult size, and difficulty in reaching arc-shaped "grooves" to achieve automatic production and convenient production. The effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention will be further described below in conjunction with the accompanying drawings, but the present invention is not limited to the following examples.

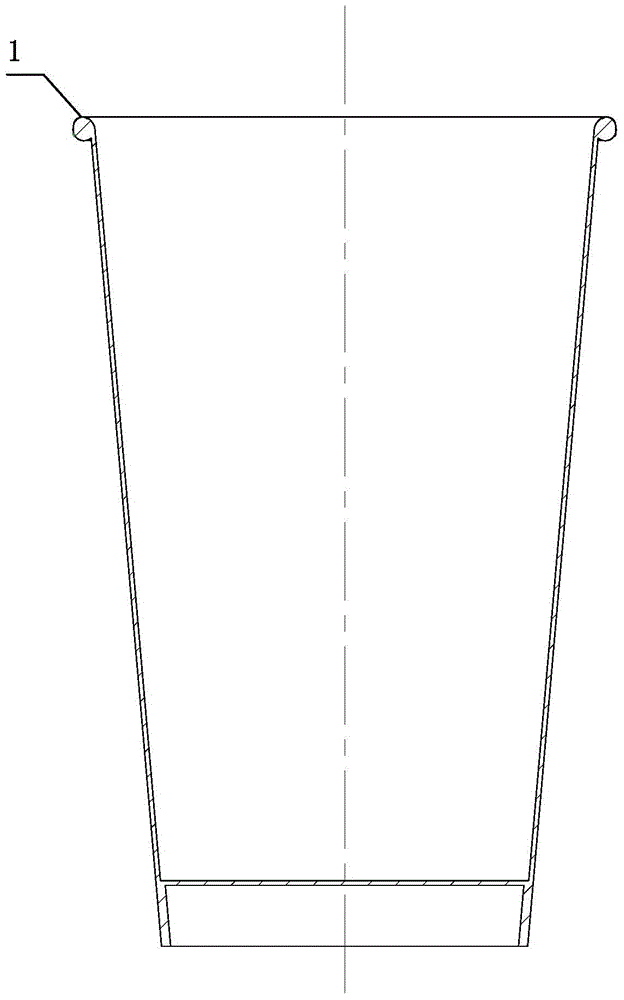

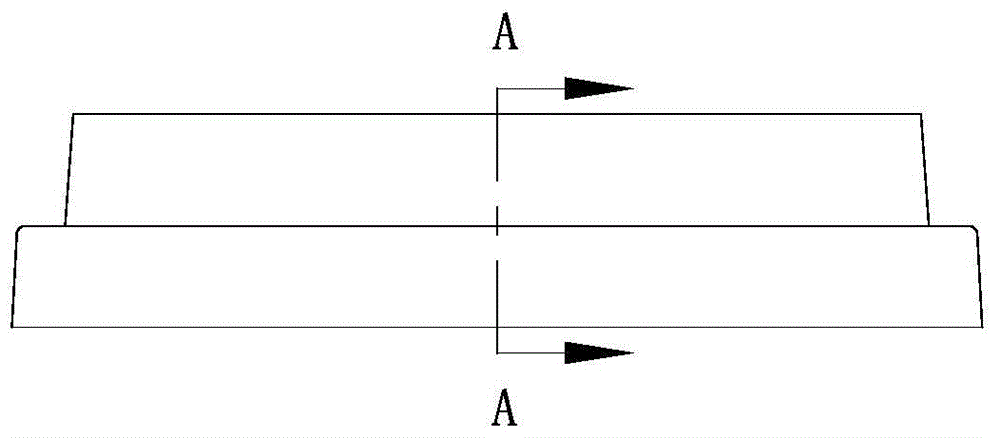

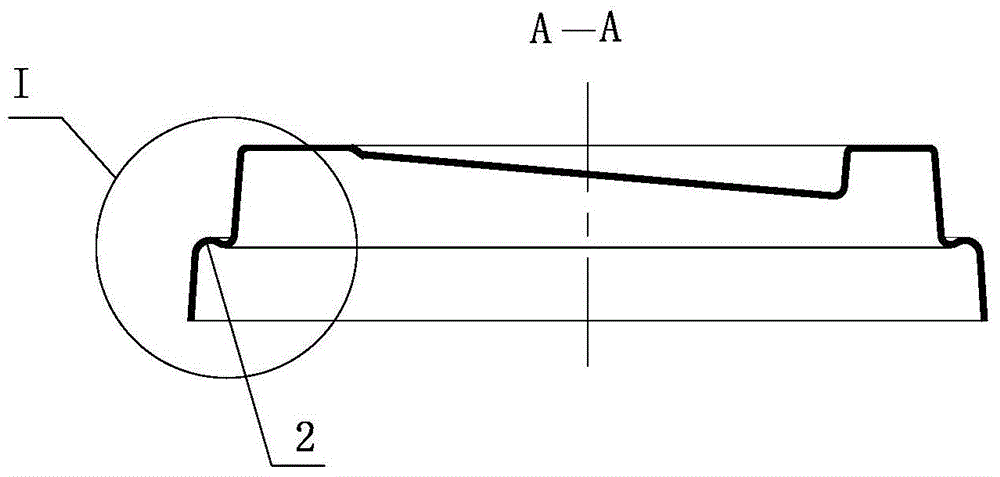

[0048] Such as Figure 3.1 , Figure 3.2 As shown, a plant fiber molded cup lid with anti-loose inner convex strips, including arc groove 2, cup lid side straight edge 3, pit 4, inner convex strip 5 and ventilating boss 8, arc groove 2 on top of the straight edge 3 on the lid side; or, as Figure 3.5 As shown, a plant fiber molded cup lid with anti-loosening inner convex strips contains arc-shaped grooves 2, straight sides 3 on the side of the cup lid, pits 4, inner convex strips 5 and a flat top. This flat top structure The cup lid of the cup does not have a ventilation boss 8, and the arc-shaped groove 2 is positioned at the top of the straight side 3 of the cup lid side.

[0049] Such as Figure 3.1 ,Such as Figure 3.2 As shown, the upper end of the cup cover is provided with a ventilating bos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com