A fabric continuous production device

A production device and fabric technology, applied in thin material handling, transportation and packaging, winding strips, etc., can solve problems such as affecting production efficiency, affecting fabric judgment, and inaccurate detection results, ensuring continuous and improving Production efficiency, the effect of continuous transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with embodiment the present invention is further described:

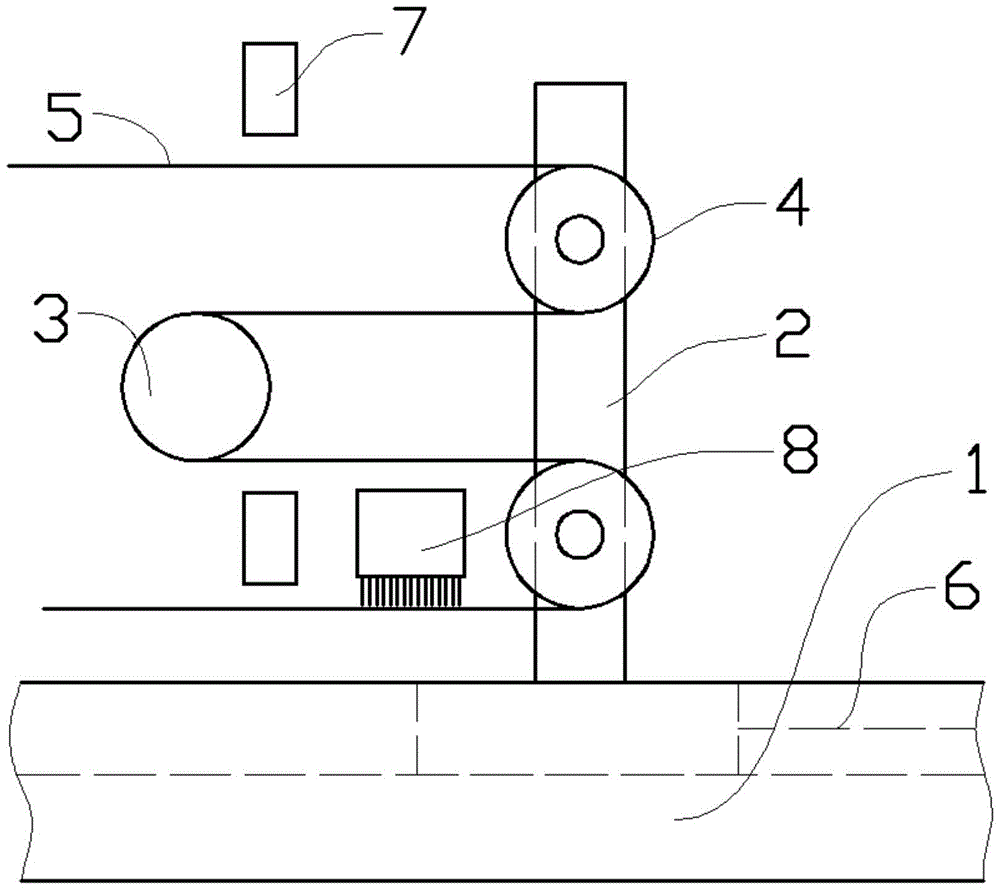

[0010] Such as figure 1 As shown in the embodiment, the cloth continuous production device includes a bottom rail 1, a sliding column 2, a fixed roller 3, and a follower roller 4; it is characterized in that: a sliding groove is designed on the bottom rail 1, and the sliding column 2 are used in pairs, and can be vertically and horizontally slidably assembled in the sliding groove, and the follower roller 4 is assembled on the sliding column 2 in a manner of placing up and down horizontally, and the follower roller 4 can follow the The moving roller shaft is rotatably mounted on the sliding column 2, and the fixed roller 3 is rotatably mounted on the frame around the fixed roller shaft. The fixed roller 3 is relatively parallel to the follower roller 4. The follower roller 4 is wound through, and the bottom of the sliding column 2 is connected with the power module through a chain 6 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com