The middle position operating device of the straight-arm truck-mounted crane

A truck-mounted crane and position operation technology, which is applied in the direction of lighting devices, lighting devices, lighting device components, etc., can solve the problems of limited installation angle of multi-way valves, inconvenient up and down for operators, and inability to perform bilateral operations, etc. To achieve the effect of flexible and convenient operation of the truck-mounted crane, convenient intuitive operation, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

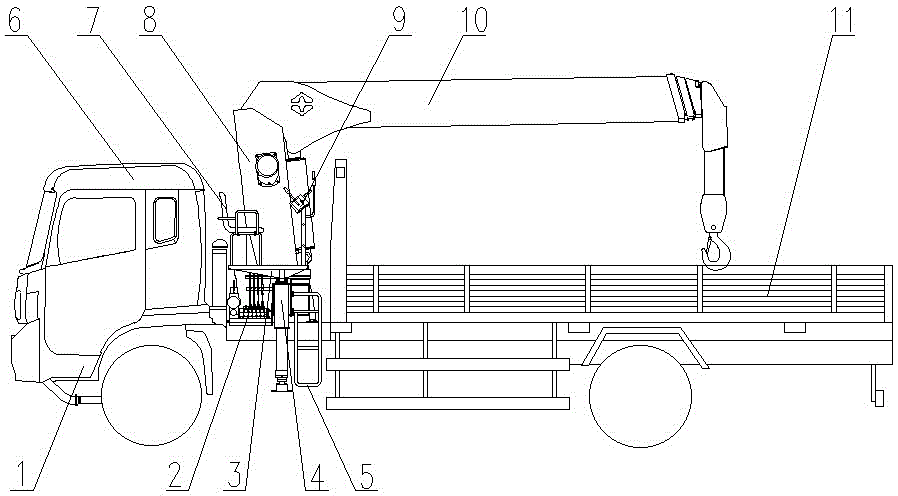

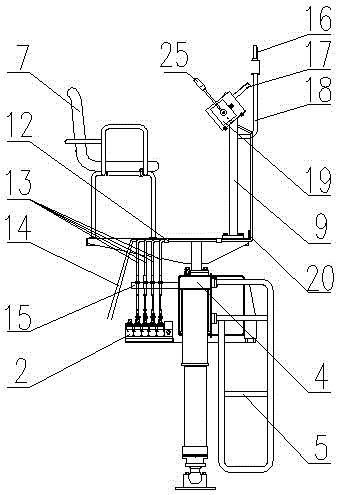

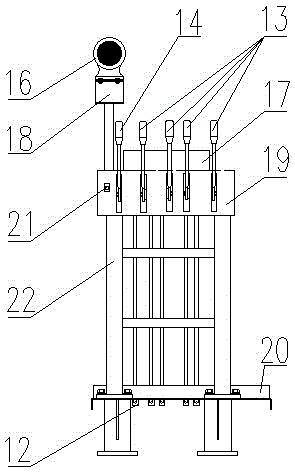

[0023] Such as Figure 1-Figure 4 As shown, the neutral operating device of the straight-arm type truck-mounted crane includes a multi-way valve 2, a support platform 3 and an operating rod assembly 9. The support platform 3 is installed on the base beam 4 of the crane 10, and the support platform 3 Located between the cab 6 and the container 11, on one side of the crane column 8, the operating rod assembly 9 is arranged on the top of the support platform 3, and the multi-way valve 2 is arranged below the support platform 3;

[0024] The operating rod assembly 9 includes a multi-way valve controller 13, a remote throttle cable 14, an operating box 19, a bracket 22 and an operating handle 25, the bottom end of the bracket 22 is connected with the support platform 3, and the top end of the bracket 22 is installed There is an operation box 19, one end of the operation handle 25 is installed inside the operation box 19, the multi-way valve controller 13 is a push-pull flexible sha...

Embodiment 2

[0031] Such as Figure 1-Figure 4 As shown, the neutral operating device of the straight-arm type truck-mounted crane includes a multi-way valve 2, a support platform 3 and an operating rod assembly 9. The support platform 3 is installed on the base beam 4 of the crane 10, and the support platform 3 Located between the cab 6 and the container 11, on one side of the crane column 8, the operating rod assembly 9 is arranged on the top of the support platform 3, and the multi-way valve 2 is arranged below the support platform 3;

[0032] The operating rod assembly 9 includes a multi-way valve controller 13, a remote throttle cable 14, an operating box 19, a bracket 22 and an operating handle 25, the bottom end of the bracket 22 is connected with the support platform 3, and the top end of the bracket 22 is installed There is an operation box 19, one end of the operation handle 25 is installed inside the operation box 19, the multi-way valve controller 13 is a push-pull flexible sha...

Embodiment 3

[0042] Such as Figure 1-Figure 4As shown, the neutral operating device of the straight-arm type truck-mounted crane includes a multi-way valve 2, a support platform 3 and an operating rod assembly 9. The support platform 3 is installed on the base beam 4 of the crane 10, and the support platform 3 Located between the cab 6 and the container 11, on one side of the crane column 8, the operating rod assembly 9 is arranged on the top of the support platform 3, and the multi-way valve 2 is arranged below the support platform 3;

[0043] The operating rod assembly 9 includes a multi-way valve controller 13, a remote throttle cable 14, an operating box 19, a bracket 22 and an operating handle 25, the bottom end of the bracket 22 is connected with the support platform 3, and the top end of the bracket 22 is installed There is an operation box 19, one end of the operation handle 25 is installed inside the operation box 19, the multi-way valve controller 13 is a push-pull flexible shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com