A kind of biomass pyrolysis liquid fuel engine oil composition

A biomass pyrolysis, liquid fuel technology, applied in the direction of lubricating composition, etc., can solve the problems of injection system wear, difficult compression ignition of bio-oil, technical difficulties, etc., and achieves good low temperature startability, less carbon deposition, and shear resistance. and anti-friction and anti-corrosion properties

Active Publication Date: 2016-06-01

GUANGXI UNIV

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In addition, bio-oil is difficult to compress and ignite in diesel engines, and direct use will cause severe wear and carbon deposition in the injection system, and there are still certain technical difficulties

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

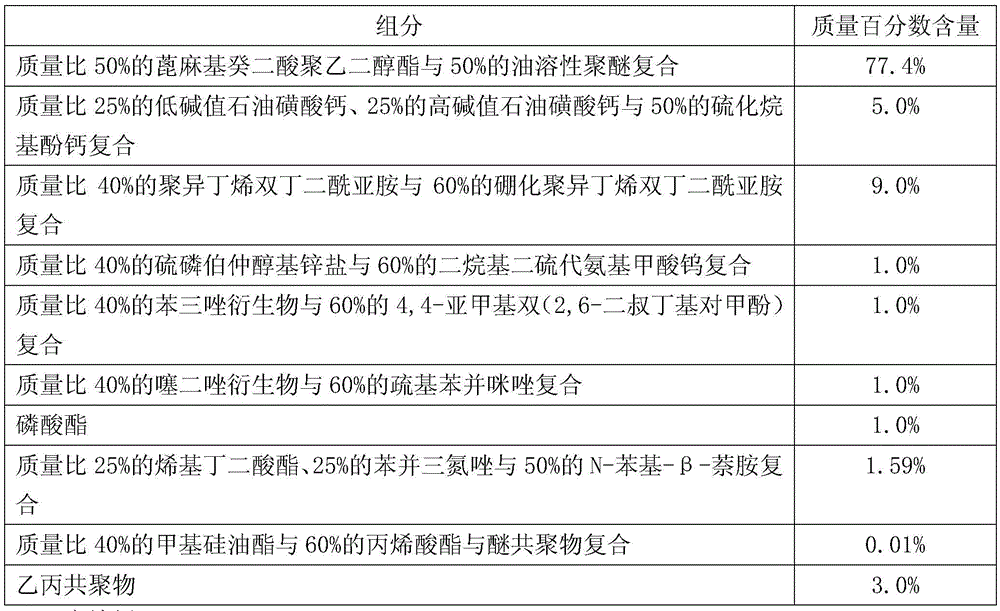

Embodiment 1

[0021] It is formed by blending the following components in mass percentage:

[0022]

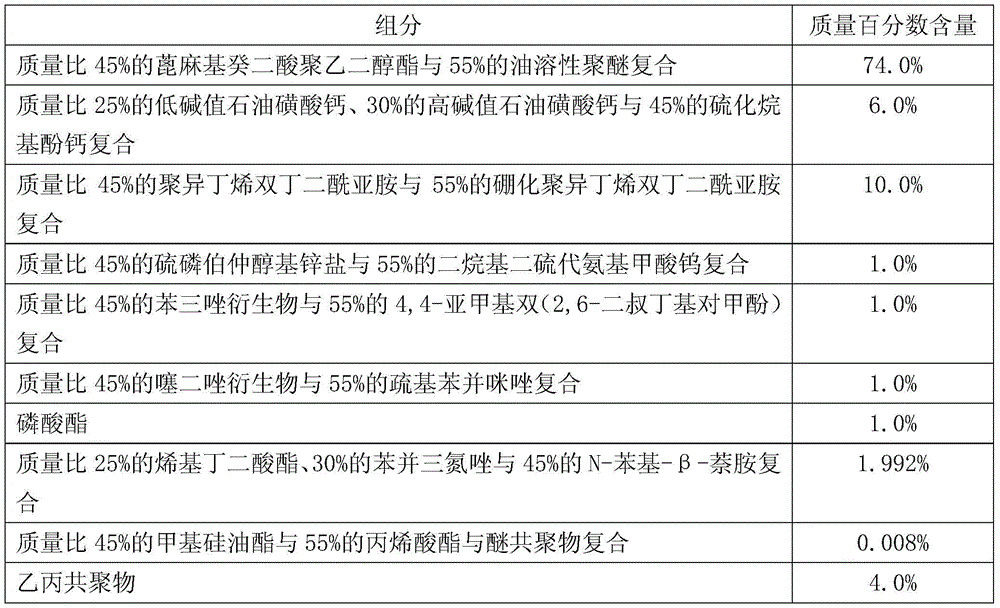

Embodiment 2

[0024] It is formed by blending the following components in mass percentage:

[0025]

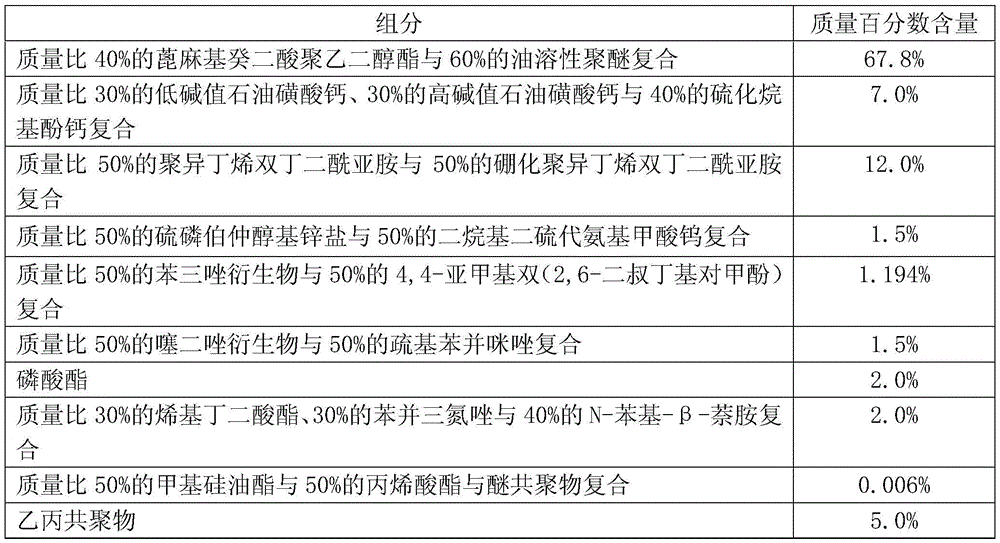

Embodiment 3

[0027] It is formed by blending the following components in mass percentage:

[0028]

[0029] The main physical and chemical index of embodiment 2 product:

[0030]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a biomass pyrolysis liquid fuel engine oil composition. Oil soluble polyether and castor-based sebacic acid polyethylene glycol ester are adopted as base oil, and multiple compound additives are compounded. Multiple compound additives include an antirust agent, an antioxidant preservative, an antifoaming agent, a viscosity index improver, a metal passivator, a clearing agent, a dispersing agent, an antioxidant and a reinforcing agent. The biomass pyrolysis liquid fuel engine oil composition has good clearing and dispersing effects, viscosity-temperature characteristic, base number retainability and acid neutralization capacity, can inhibit generation of polar materials such as oil sludge, can be used for reducing generation of sediments in a piston ring and a bearing bush, has good stability of resistance to high temperature oxidation, resistance to corrosion of halogen family compounds, nitrification resistance, wear resistance, shear resistance and antifriction and antiseptic properties and also has good low temperature startability, low ash content, less carbon deposit and no corrosion or rusting on moving parts.

Description

technical field [0001] The invention belongs to the field of internal combustion engine lubricants, in particular to a biomass pyrolysis liquid fuel engine oil composition. Background technique [0002] Biomass pyrolysis refers to the thermal conversion process of biomass under anaerobic or anoxic conditions. Products include: non-condensable gas, coke, and liquid three categories. The resulting liquid is called "bio-oil". The distribution of biomass pyrolysis products has a great relationship with the material itself and the reaction conditions. At moderate temperature (500-600°C), high heating rate and extremely short residence time, the main product is bio-oil. The efficiency of rapid cracking of biomass into bio-oil can be close to 60%, and its main components are compounds composed of carbon, hydrogen, oxygen and other elements. Usually a mixture of acids, aldehydes, alcohols, esters, ketones, ethers, phenols, o-cresols, syringyl alcohols, furans, lignin-derived sub...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C10M169/04

Inventor 吴长茂黄福川覃克马骁飞邓富康李康春陈彪黄旖瑶

Owner GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com