Novel wood-plastic fence

A fence and wood-plastic technology, applied to fences, building types, buildings, etc., can solve the problems of high cost, inconvenient installation, high maintenance rate, etc., and achieve the effect of low processing cost, convenient processing, and low strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

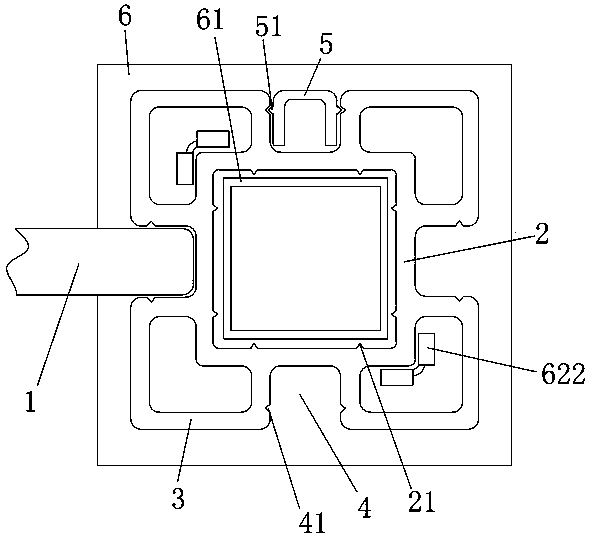

[0032] A new type of wood-plastic fence, including a base, a column mounted on the base, a fence 1 arranged between the columns and the end clamped in the column, the column includes an inner sleeve 2 and an inner sleeve 2 The outer outer wall tube 3, the inner sleeve is a square tube, the four inner walls of the square tube are each provided with two clamping ribs, and the outer wall tube 3 is provided with 4 for snapping into the fence 1 The installation grooves 4 are 4 installed corresponding to the central axis of the outer wall surface of the square tube along the length direction.

[0033] A positioning groove 41 is provided on the wall of the installation groove 4, and the fence also includes a sealing strip 5 that can be clamped in the installation groove 4 to fill the installation groove. The sealing strip 5 is provided with a position corresponding to the positioning groove. For the adapted matching ribs, the positioning groove 41 is a tapered groove, and a positioning ...

Embodiment 2

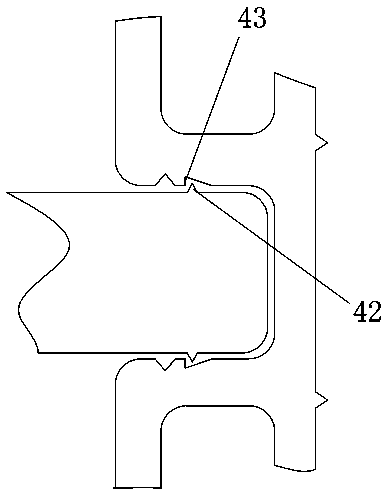

[0041] The difference from the above-mentioned embodiment is that the end of the fence 1 is inserted into the installation groove 4, and a micro-convex clip 42 is provided along the length of the column. The groove wall of the installation groove 4 is provided with a step surface facing the inner sleeve. The outer step 43 used to limit the micro-convex card strip.

Embodiment 3

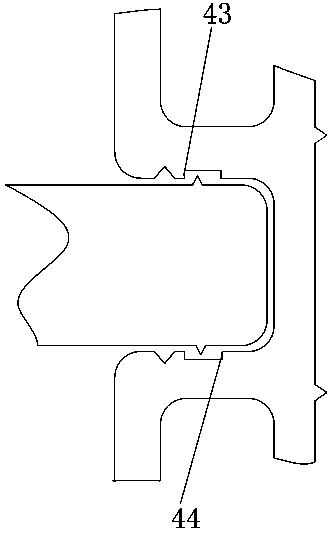

[0043] The difference from the above embodiment is that an inner step 44 is provided on the side of the mounting groove 4 opposite to the outer step 43 and close to the inner casing. A buffer groove 45 is formed between the outer step table 43 and the inner step table 44 for a limit fence, the micro-convex clip 42 is disposed in the buffer groove 45, and the matching rib 51 is disposed on the outer step The outside of the table 43. The depth of the buffer groove 45 is smaller than that of the positioning groove 41.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com