Solid wood combined outer frame end opening framing structure for threshold-free door window

A kind of technology without threshold door and door frame, applied in the direction of window/door frame, etc., can solve the problems of easy moisture absorption, wood corrosion, complex process requirements, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

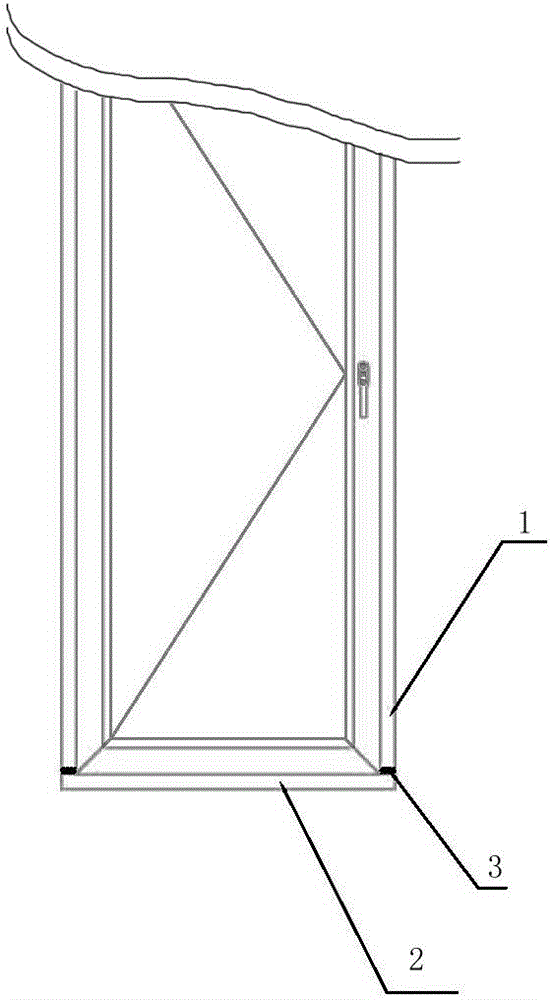

[0009] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, a frame structure of the lower opening of the outer frame of doors and windows without sills, the lower opening of the outer frame is assembled from the left and right vertical frames 1 and the lower door frame, and the lower door frame is a door frame without sill 2, the Both ends of the sillless door frame 2 are directly or indirectly fixedly connected to the lower ends of the left and right vertical frames 1 respectively.

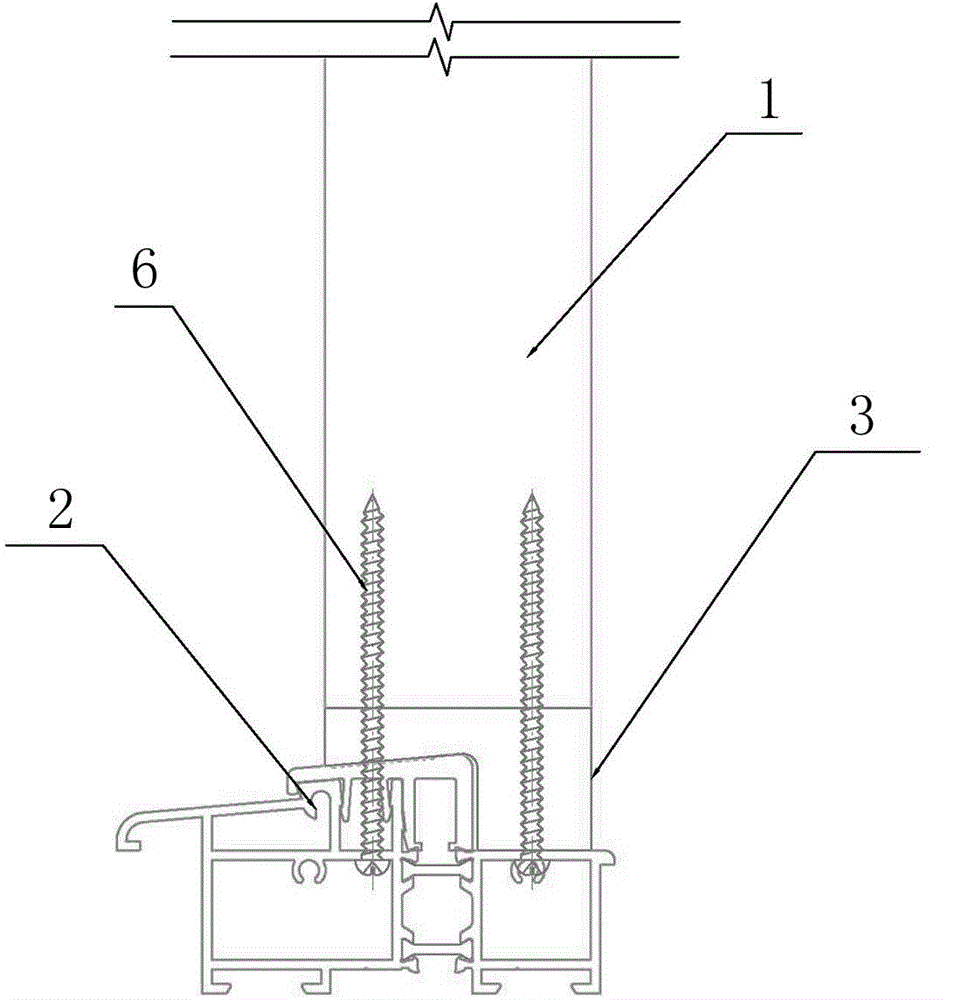

[0010] As shown in the figure, the lower ends of the left and right vertical frames 1 are placed on the upper parts of the two ends of the sill-free door frame 2, and the sill-free door spacers 3 pass through the lower end of the vertical frame 1 and the upper edge of the sill-free door frame 2. connected together.

[0011] figure 2 As shown, the two vertical frames 1 are solid wood profile frames, and the sill-free door frame 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com