Coal mining method with longwall descending layered gangue and false roof

A technology of long-wall descending and coal mining method, applied in underground mining, surface mining, earth-moving drilling and other directions, can solve the problems of low comprehensive efficiency, many production processes and high production cost, so as to reduce material consumption and improve comprehensive efficiency , the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

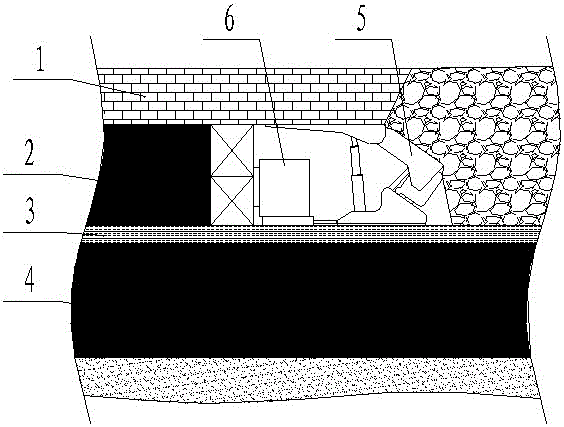

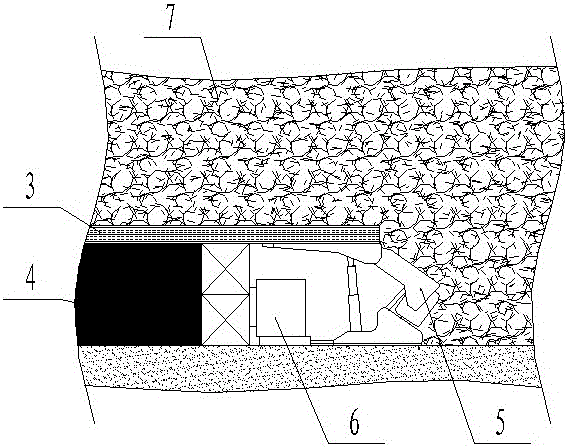

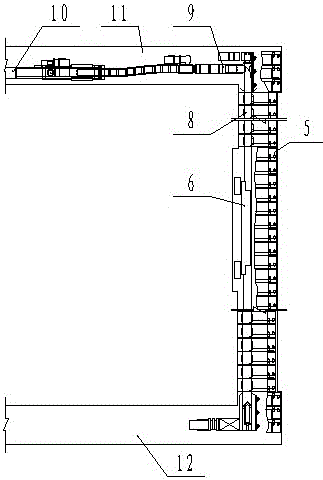

[0017] Such as figure 1 , figure 2 , image 3 As shown, the longwall descending layered gangue false roof mining method is carried out according to the following steps:

[0018] The first step is to excavate the transport roadway 11 and the air return roadway 12 on both sides of the first coal seam 1 working face, and excavate the cut hole from the transport roadway 11 to the return air roadway 12 along the first coal seam 1 working face, and the shearer 6. The scraper machine 8 and the hydraulic support 5 are installed in the cut hole of the first coal seam 1, the belt conveyor 10 and the transfer machine 9 are installed in the transport roadway 11, and then the push coal mining is carried out, and the coal mined by the shearer 6 is Transported to the ground via scraper machine 8, transfer machine 9 and belt conveyor 10;

[0019] In the second step, during the continuous advancement of the work in the first coal seam 1, the hydraulic support 5 in the goaf is gradually wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com