Four-roller breaker hydraulic control system

A technology of hydraulic control system and roller crusher, applied in mechanical equipment, grain processing and other directions, can solve the problems of short pressure holding time of hydraulic system, poor iron protection effect, short pressure holding time, etc., so as to solve the problem of short pressure holding time. , Realize automation, solve the effect of serious oil leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

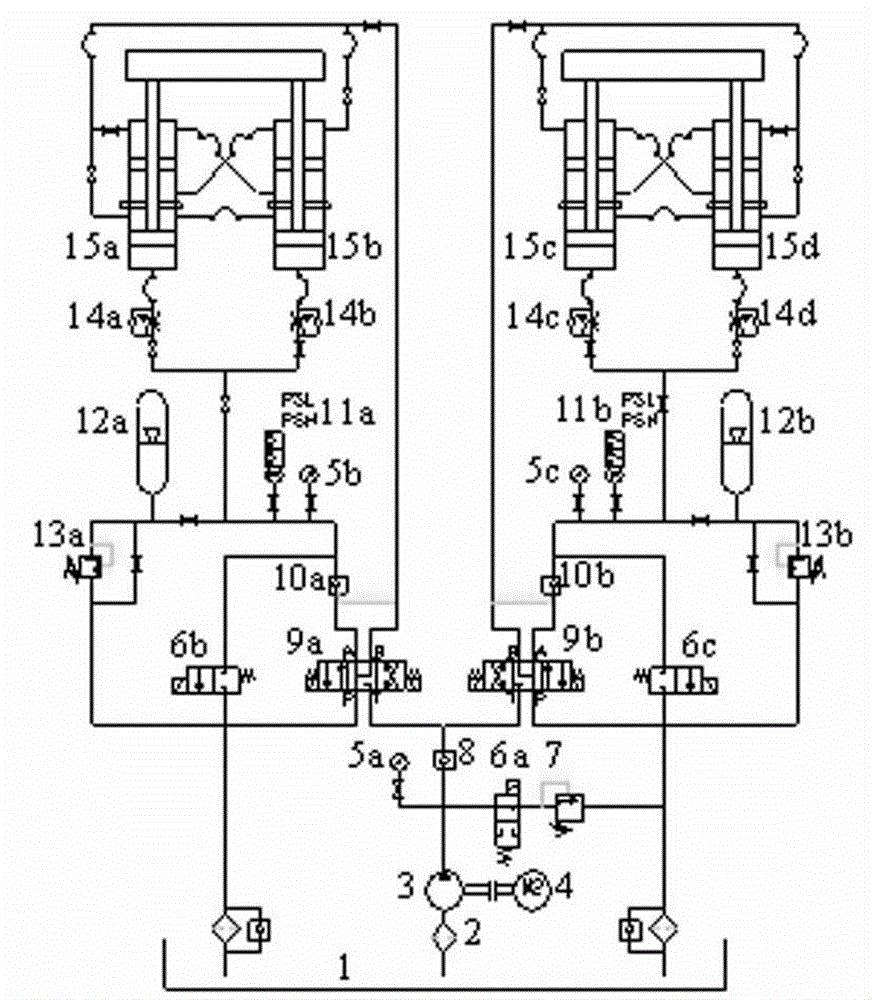

[0009] The present invention will be further explained below in conjunction with the drawings, as attached figure 1 The hydraulic control system shown includes oil tank 1, filter 2, gear pump 3, motor 4, pressure gauge 5, two-position two-way solenoid valve 6, system overflow valve 7, one-way valve 8, three-position four-way Electromagnetic reversing valve 9, hydraulic control one-way valve 10, pressure relay 11, accumulator 12, safety valve 13, one-way throttle valve 14, synchronous hydraulic cylinder 15; the mailbox 1 is connected to filter 2, filter 2 Connect gear pump 3, gear pump 3 respectively connect motor 4, pressure gauge 5, one-way valve 8, two-position two-way solenoid valve 6, one-way valve 8 respectively connect two three-position four-way solenoid valve 9 , The three-position four-way electromagnetic reversing valve 9 is respectively connected to the hydraulic control check valve 10, the parallel synchronous hydraulic cylinder 15, and the safety valve 13, the sync...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com