Slow-release high-slump-retaining type water reducing agent and preparation method thereof

A high-slump-preserving, water-reducing agent technology, applied in the field of water-reducing agents, can solve problems such as the failure of normal pouring of concrete, difficulties in pumping or dense molding, waste of manpower and material resources, etc., to ensure performance, improve adsorption-dispersion capacity, Good adsorption and dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

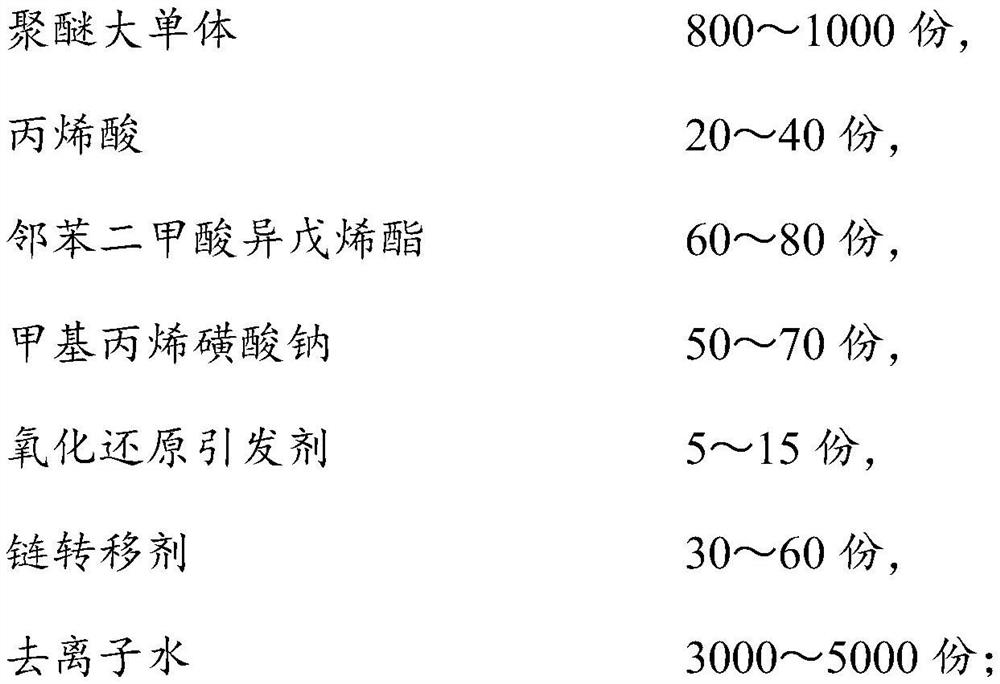

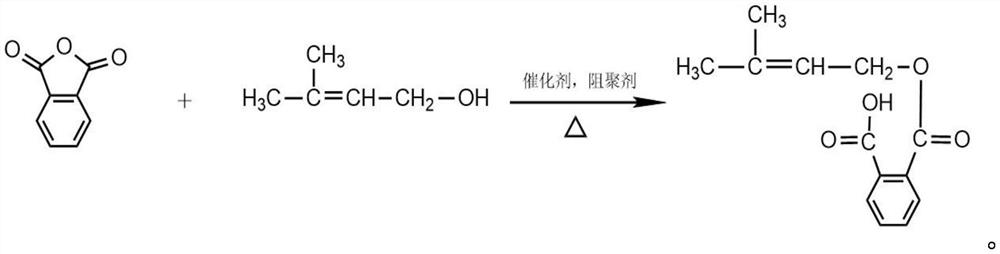

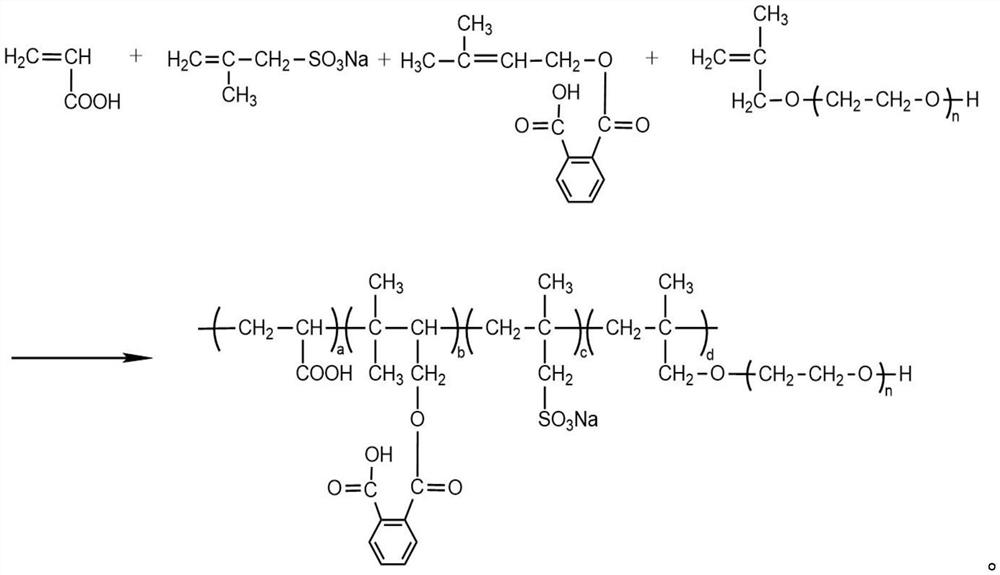

[0032] A slow-release high-slump-retaining water reducer, comprising the following raw materials in parts by mass: 800 parts of polyether macromonomer, 20 parts of acrylic acid, 60 parts of isopentenyl phthalate, and 50 parts of sodium methacrylate , 5 parts of redox initiator, 30 parts of chain transfer agent, 3000 parts of deionized water;

[0033] The preparation method of the slow-release high slump-retaining water reducer comprises the following steps:

[0034] Step 1: Take the polyether macromonomer in parts by mass and place it in a reaction container, add 4 / 10 parts by mass of deionized water, stir at a speed of 100r / min until the polyether macromonomer is completely dissolved, and then add The parts by mass of acrylic acid, isopentenyl phthalate, sodium methacrylate and 5 / 10 parts by mass of deionized water are heated in a water bath at a temperature of 60°C and stirred for 2 to 3 hours at the same time to obtain the monomer mixed solution;

[0035] Step 2: Take the...

Embodiment 2

[0038] A slow-release high-slump-retaining water reducer, including the following raw materials in parts by mass: 1,000 parts of polyether macromonomer, 40 parts of acrylic acid, 80 parts of isopentenyl phthalate, and 70 parts of sodium methacrylate , 15 parts of redox initiator, 60 parts of chain transfer agent, 5000 parts of deionized water;

[0039] The preparation method of the slow-release high slump-retaining water reducer comprises the following steps:

[0040] Step 1: Take the polyether macromonomer in parts by mass and place it in a reaction container, add 4 / 10 parts by mass of deionized water, stir at a speed of 300r / min until the polyether macromonomer is completely dissolved, and then add The parts by mass of acrylic acid, isopentenyl phthalate, sodium methacryl sulfonate and 5 / 10 parts by mass of deionized water are heated in a water bath at a temperature of 80°C and stirred for 3 hours at the same time to obtain a monomer mixture ;

[0041] Step 2: Take the red...

Embodiment 3

[0044] A slow-release high-slump-retaining water reducer, comprising the following raw materials in parts by mass: 900 parts of polyether macromonomer, 30 parts of acrylic acid, 70 parts of isopentenyl phthalate, and 60 parts of sodium methacrylate , 10 parts of redox initiator, 45 parts of chain transfer agent, 4000 parts of deionized water;

[0045] The preparation method of the slow-release high slump-retaining water reducer comprises the following steps:

[0046]Step 1: Take the polyether macromonomer in parts by mass and place it in a reaction container, add 4 / 10 parts by mass of deionized water, stir at a speed of 200r / min until the polyether macromonomer is completely dissolved, and then add The parts by mass of acrylic acid, isopentenyl phthalate, sodium methacrylate and 5 / 10 parts by mass of deionized water are heated in a water bath at a temperature of 70°C and stirred for 2 hours at the same time to obtain a monomer mixture ;

[0047] Step 2: Take the redox initia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com