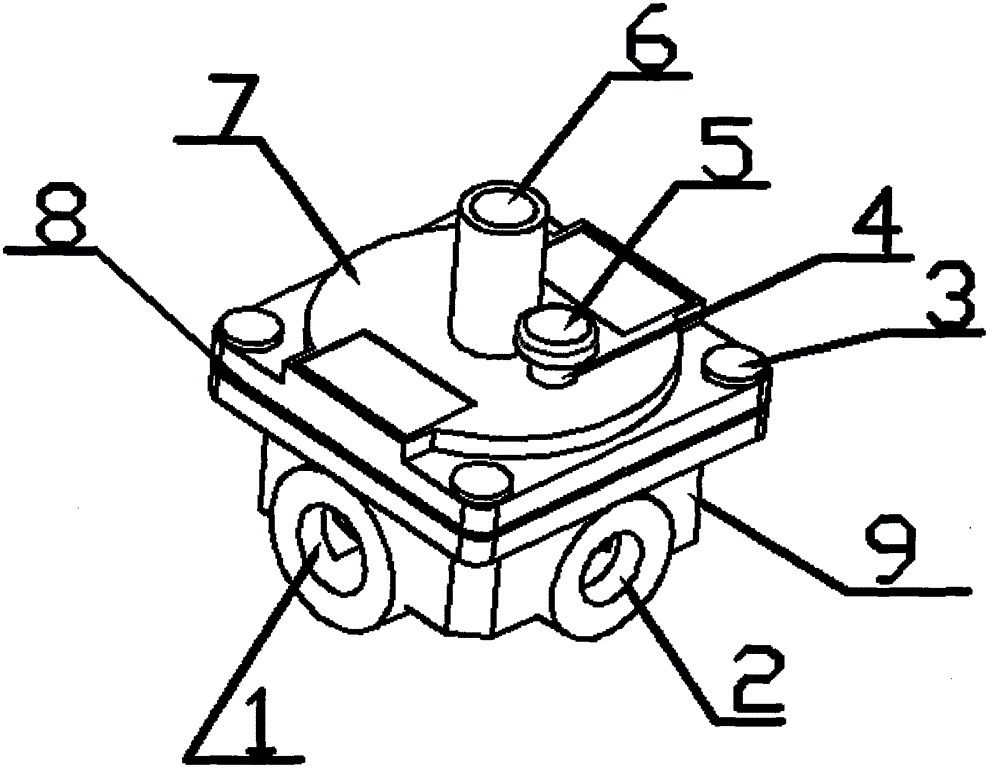

A double gas source automatic selection valve

An automatic selection, dual gas source technology, applied in valve details, multi-way valves, valve devices, etc., can solve the problems of selection valves not working properly, safety and hidden dangers, etc., and achieve the effect of simple structure, safe use and small pressure chamber

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

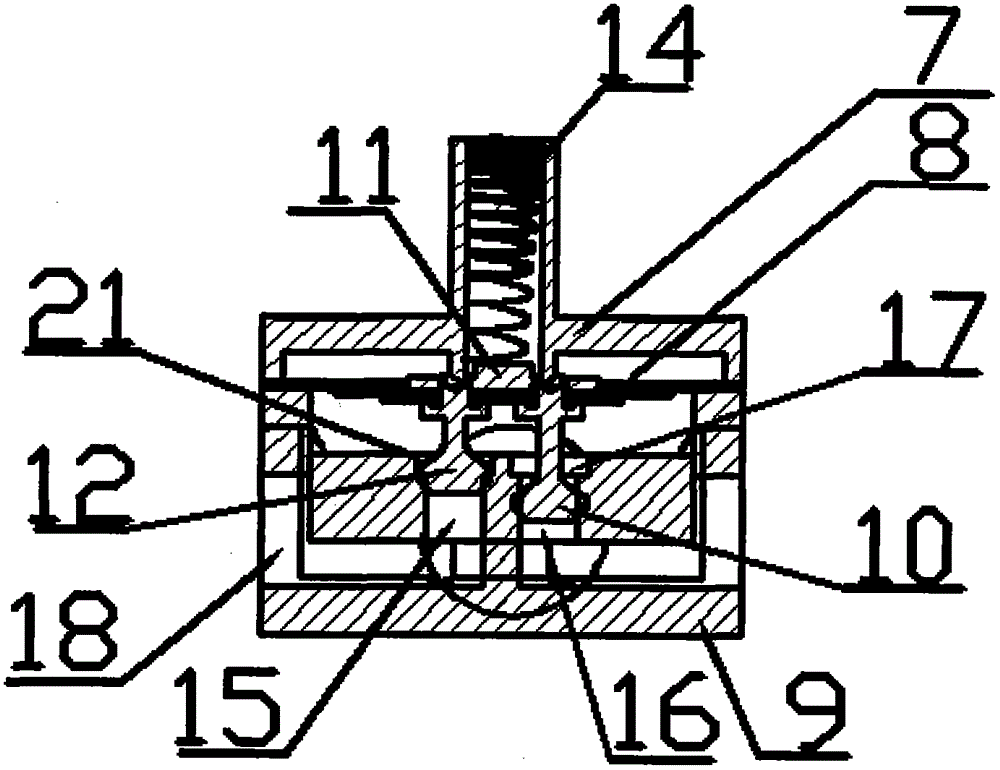

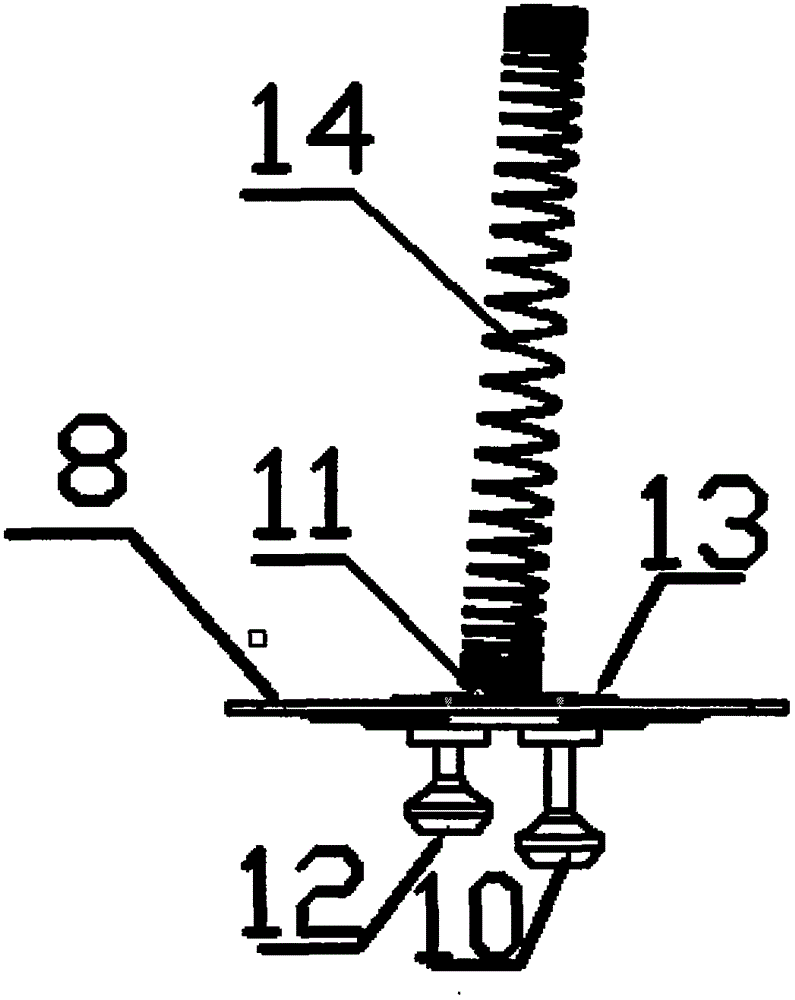

[0022] The spring resistance critical value range is set to 2.4kpa-2.5kpa, the low-pressure valve is designed to open normally, the natural gas intake pressure 2kpa (low-pressure gas) passes through the low-pressure valve, and its pressure 2kpa is less than the spring resistance critical value, and the spring acts on the membrane to push the high-pressure seal Cone, the lower cone surface of the high-pressure sealing cone is connected with the sealing ring to close the high-pressure valve, and the natural gas passes through the pressure reducing valve from the gas outlet to complete the low-pressure gas delivery process; the inlet pressure of liquefied gas is 2.8kpa (high-pressure gas), and its pressure is 2.8 kpa is greater than the critical value of spring resistance, driving the lower cone surface of the high-pressure sealing cone to leave the sealing ring 1, the high-pressure sealing cone pushes the membrane to move upward, the high-pressure valve opens, and drives the low-p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com