Patents

Literature

31results about How to "No manual controls" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

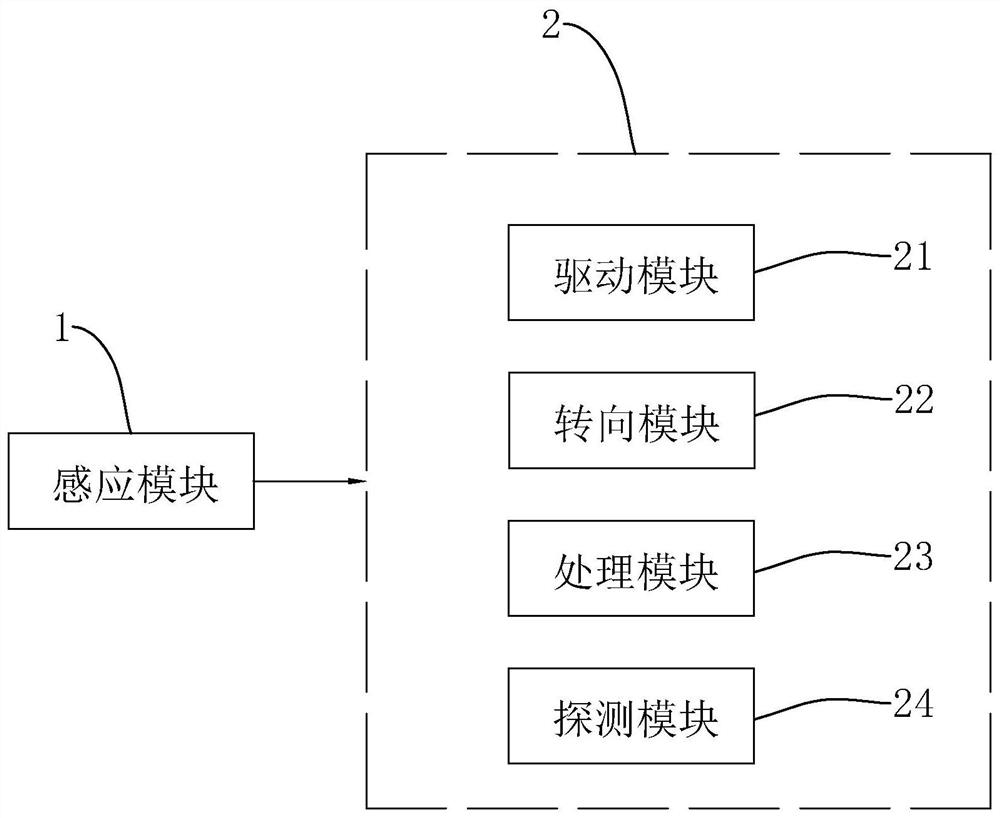

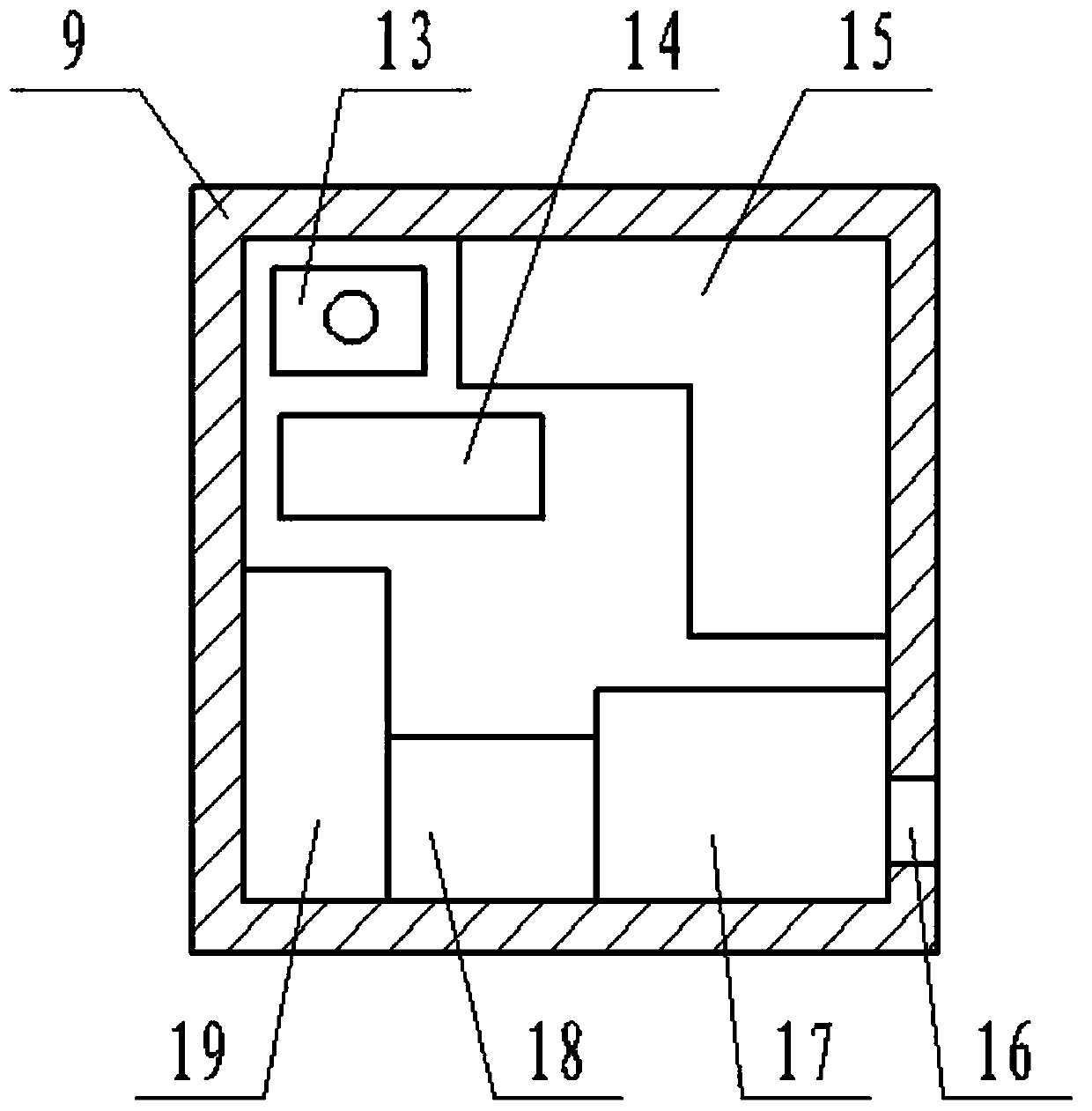

Smart home automatic control method and device

InactiveCN106919056ARealize automatic controlNo manual controlsComputer controlProgramme total factory controlAutomatic controlHome appliance

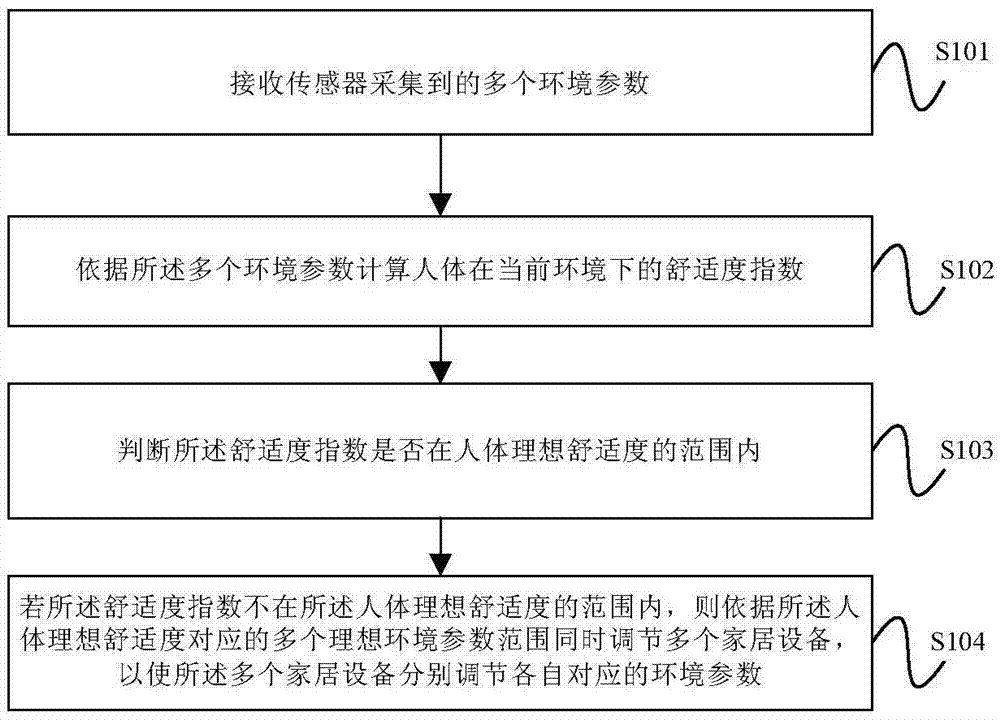

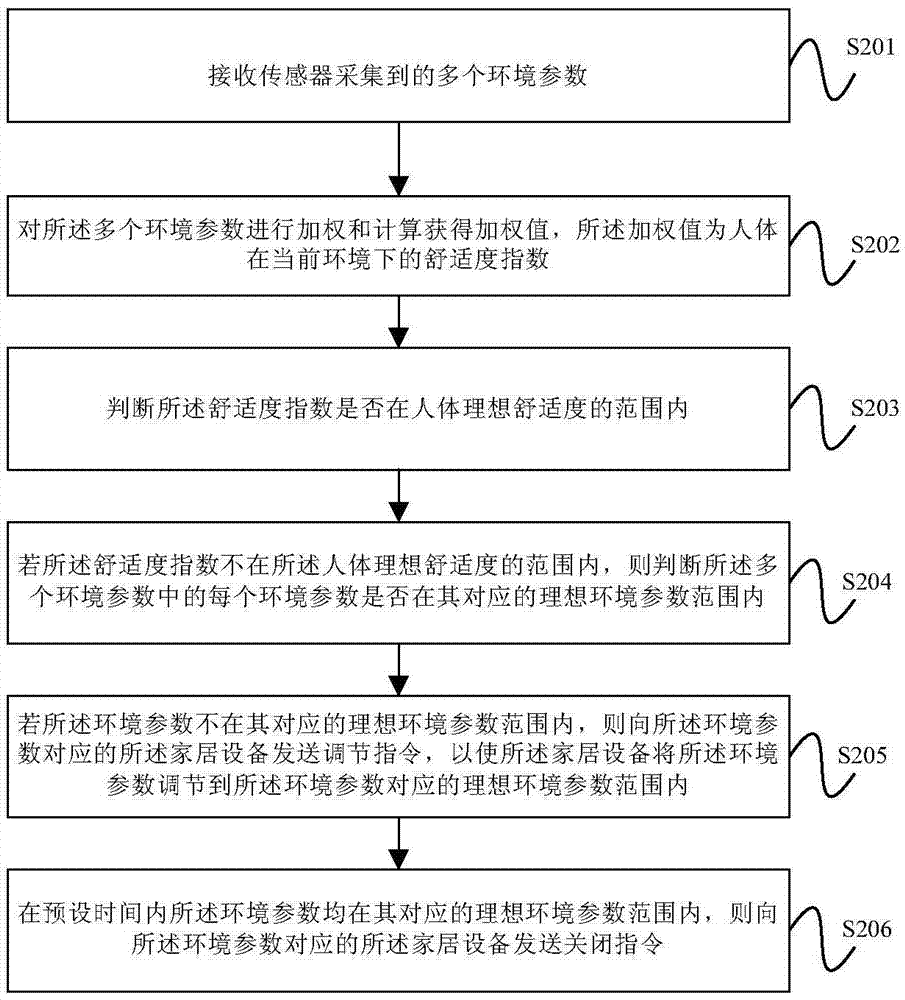

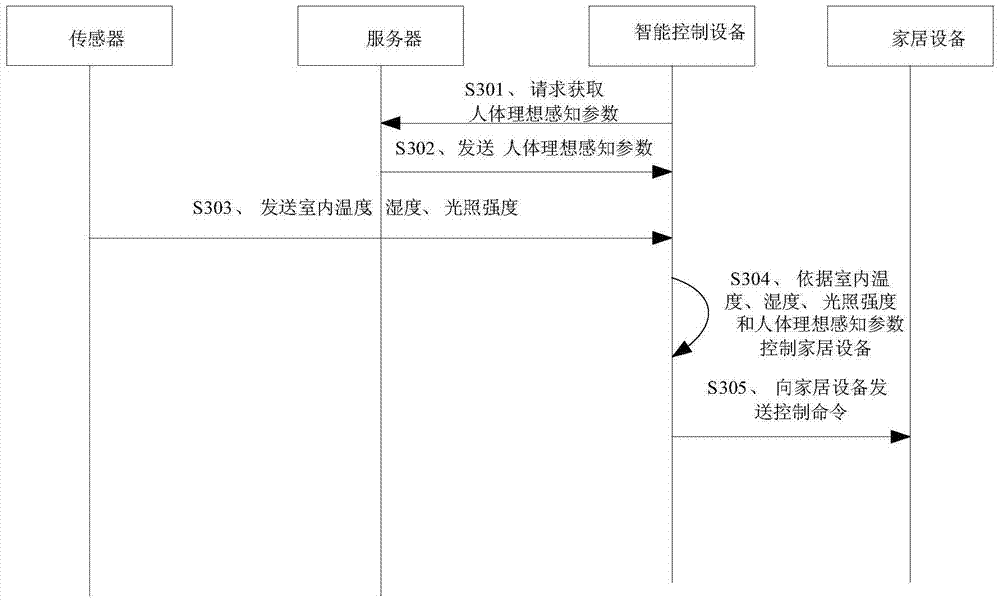

An embodiment of the invention provides a smart home automatic control method and device. The method comprises the following steps: receiving a plurality of environmental parameters collected by sensors; calculating a comfort index of a human body under the current environment according to the plurality of environmental parameters; judging whether the comfort index is within an ideal human body comfort level range; and if the comfort index is not within the ideal human body comfort level range, adjusting a plurality of home appliances simultaneously according to a plurality of ideal environment parameter ranges corresponding to the ideal human body comfort level to enable the plurality of home appliances to adjust corresponding environmental parameters respectively. According to the smart home automatic control method and device, through control of the home appliances by an intelligent control device, automatic control of the home appliances is realized instead of manual control of a user; and besides, the intelligent control device controls the plurality of home appliances according to indoor temperature, humidity, light intensity and the plurality of ideal environment parameter ranges to enable the indoor environment to reach an optimum body-sensed comfort level.

Owner:BEIJING QIHOO TECH CO LTD +1

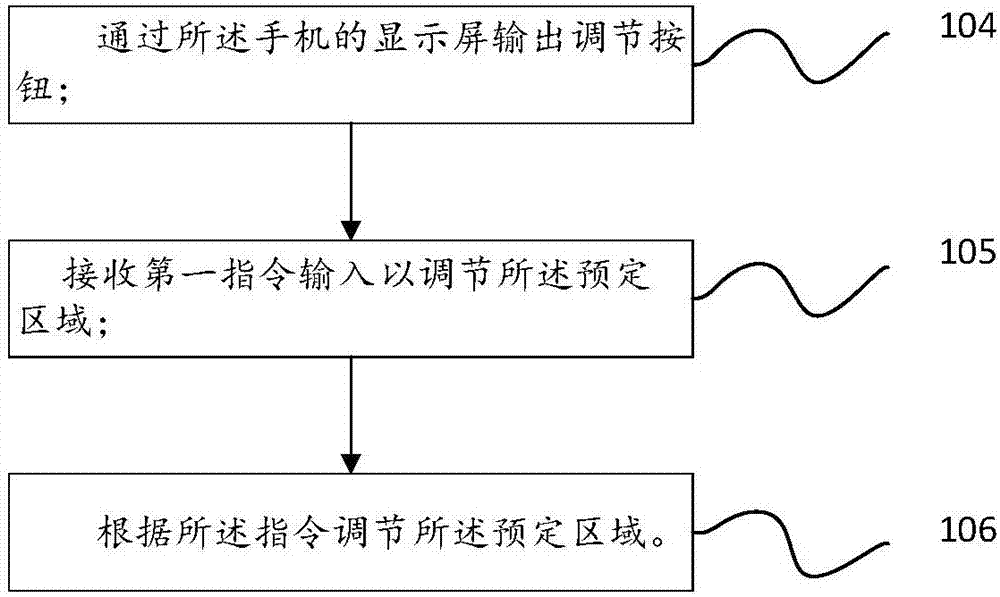

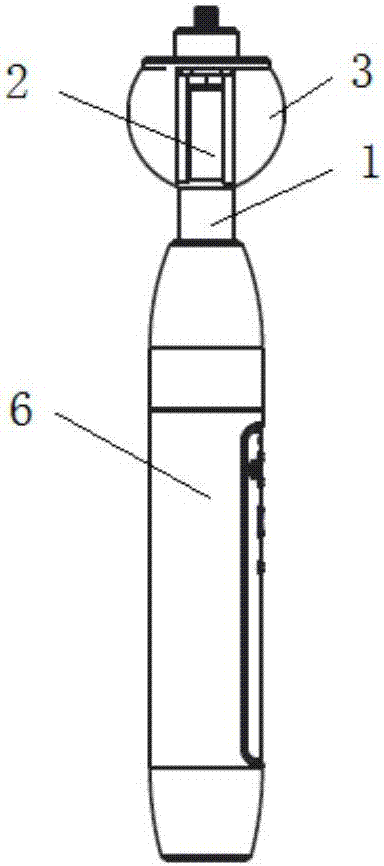

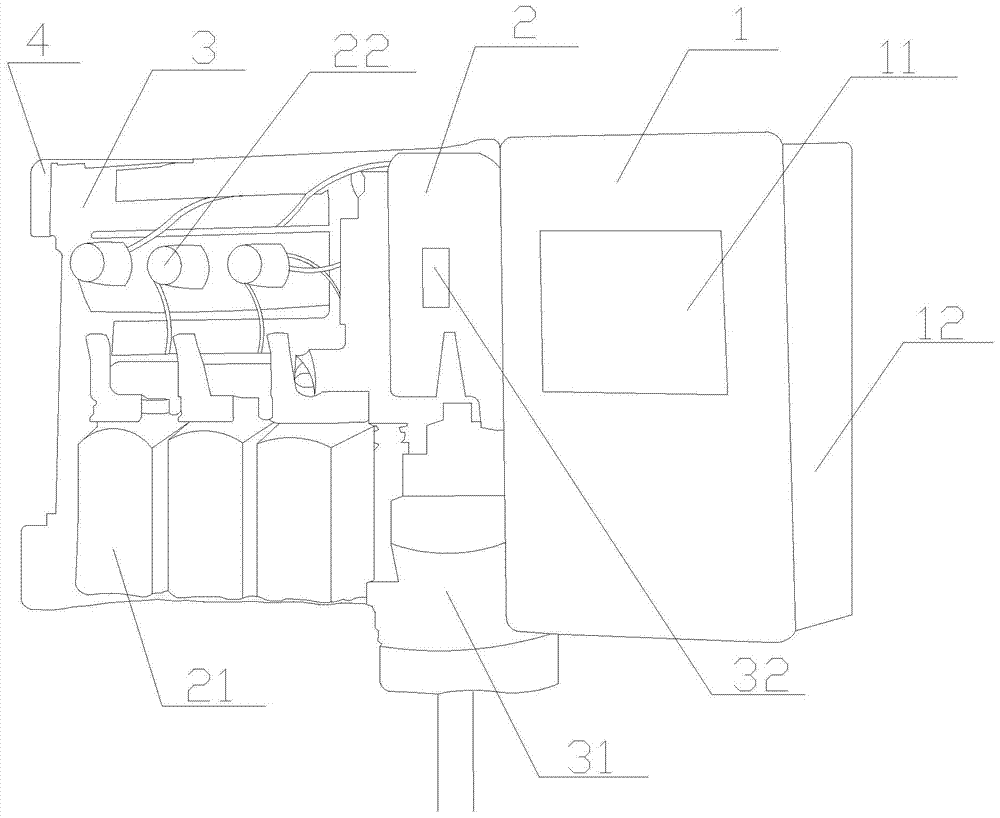

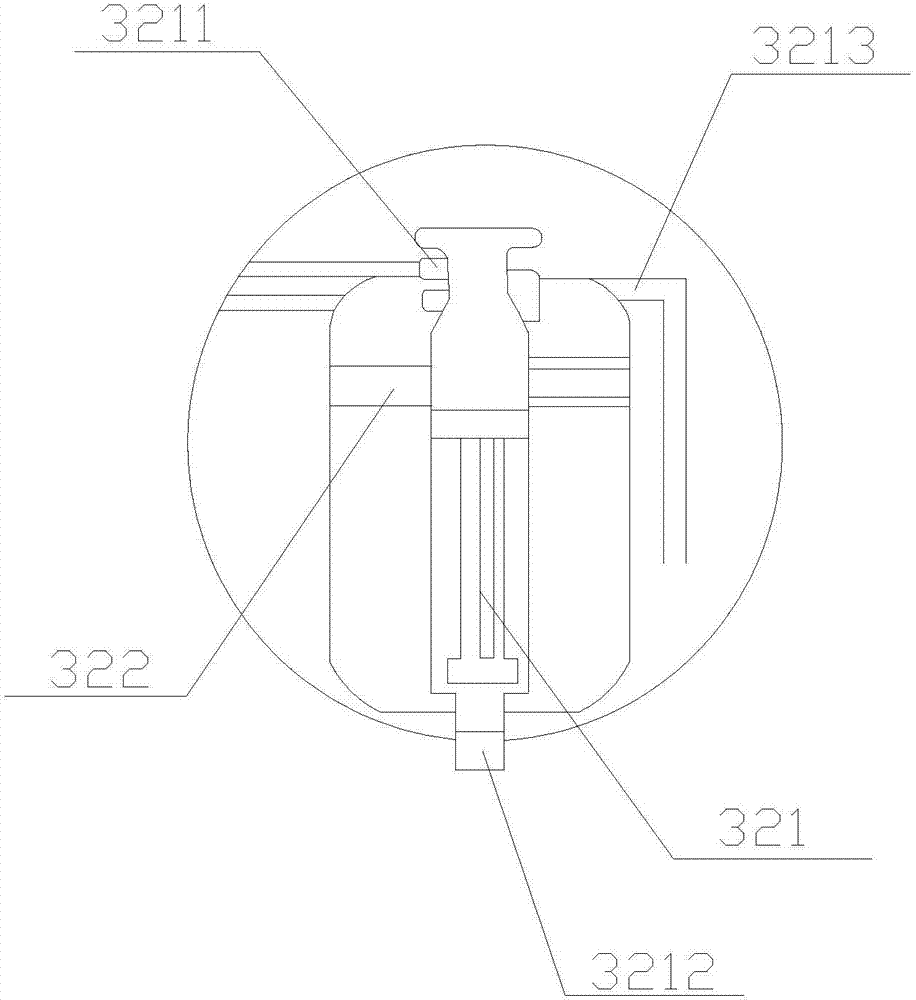

Self-photographing method and self-photographing device with face tracking function

InactiveCN107018310ANo manual controlsEasy to useTelevision system detailsCharacter and pattern recognitionComputer graphics (images)Computer vision

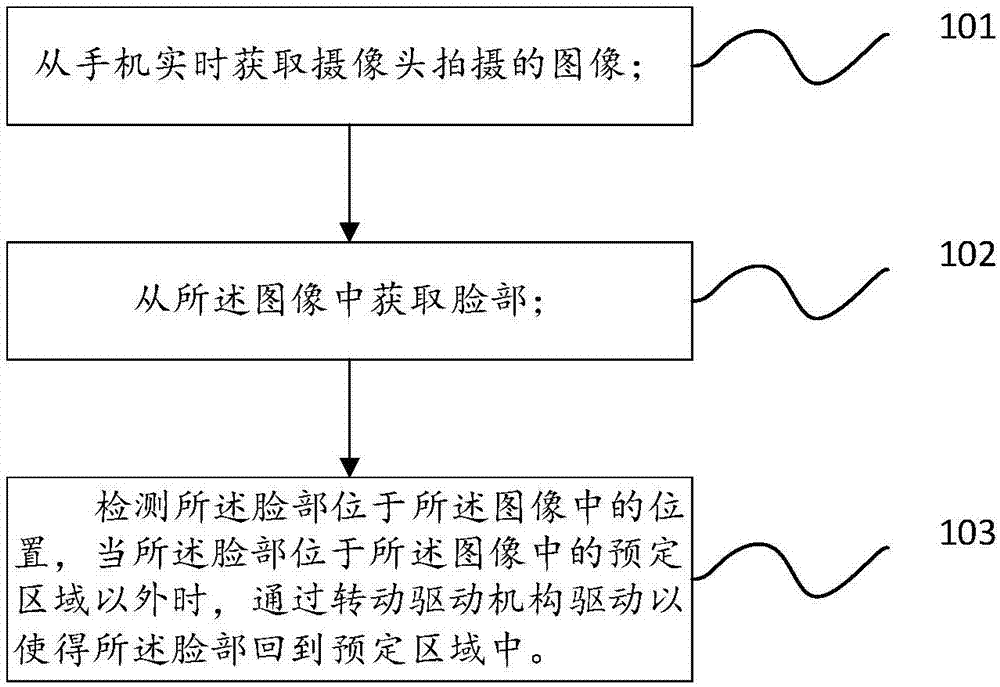

The invention discloses a self-photographing method and a self-photographing device with a face tracking function. The self-photographing method comprises the following steps: acquiring an image acquired by a camera from a mobile phone in real time; acquiring a face from the image; and detecting the position of the face in the image, and when the face is located outside a predetermined area in the image, driving the image to return to the predetermined area by a rotation driving mechanism. According to the self-photographing method provided by the invention, the self-photographing device is provided with the rotation driving mechanism, the image acquired by the camera is detected in real time during a photographing process by the mobile phone; when the face is outside the image, the rotation driving mechanism drives the self-photographing device to make the face return to the image, therefore, the face of a self-photographer is ensured to be always within the photographing range of the camera, and manual control is not needed and the use is more convenient.

Owner:罗云富

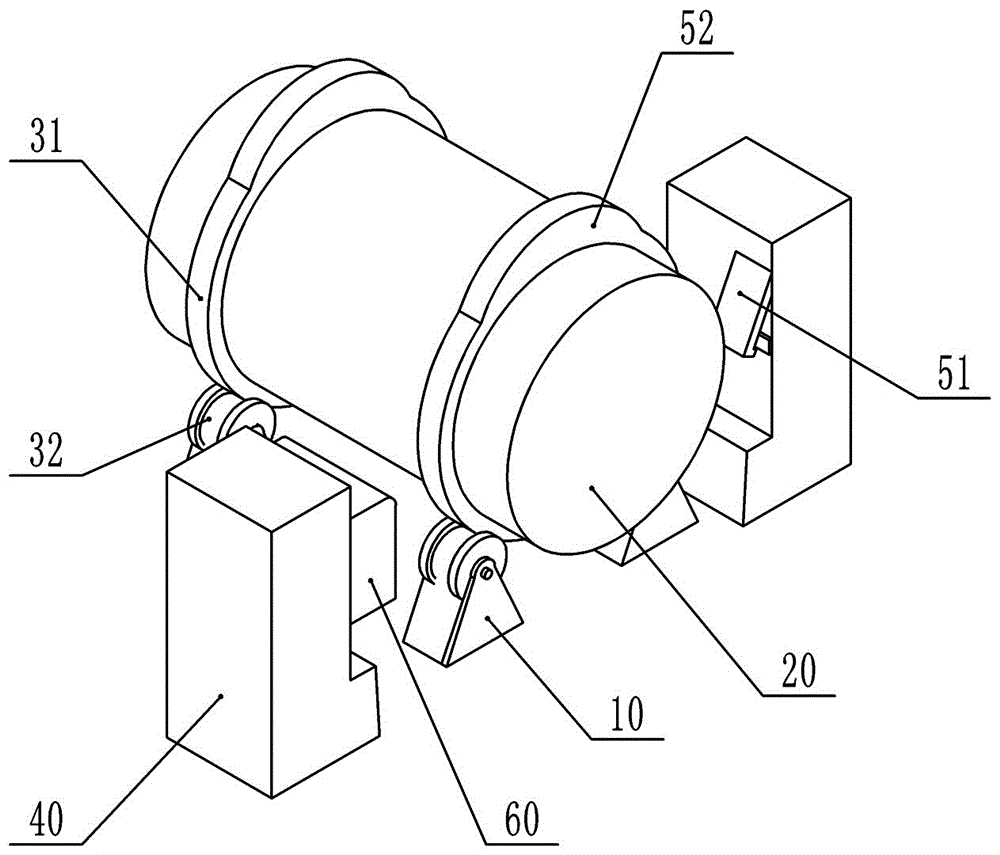

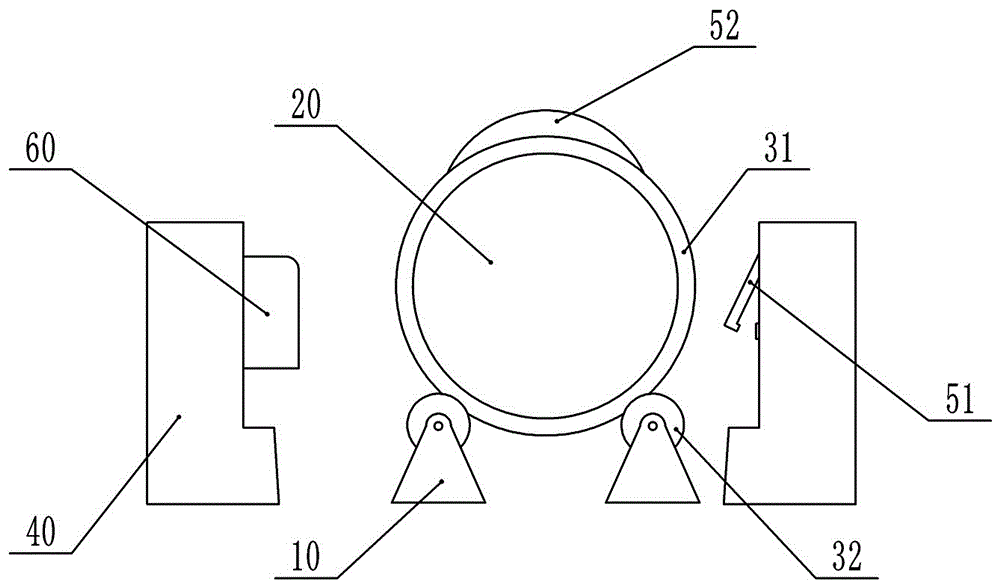

Shot blasting machine

InactiveCN105945711AImprove efficiencyAchieve intermittent closureEdge grinding machinesPolishing machinesEngineeringMachine tool

The invention belongs to an abrasive jet machine tool or device and particularly discloses a shot blasting machine comprising a base, a first friction wheel, a second friction wheel, a motor and a roller and also comprising an electromagnet, a normally-opened trigger switch and a rack, wherein the second friction wheel is matched with the first friction wheel; the roller is provided with a steel shot; the surface of the roller is sleeved by the first friction wheel; the second friction wheel is arranged on the base and presses against the second friction wheel; the motor is connected with the second friction wheel through a conveying belt; the normally-opened trigger switch is electrically connected with the electromagnetic; and the electromagnet is fixedly arranged on the rack and is located above the steel shot. Compared with the traditional shot blasting machine, the shot blasting machine has the advantages that besides a way of driving the roller to rotate by the motor, a way of arranging the electromagnet is adopted, so that the rotating speed of the roller is kept stable, the motion of the steel shot is enhanced, and furthermore the shot blasting efficiency is effectively increased.

Owner:CHONGQING YINGRUISHENG DIE CASTING

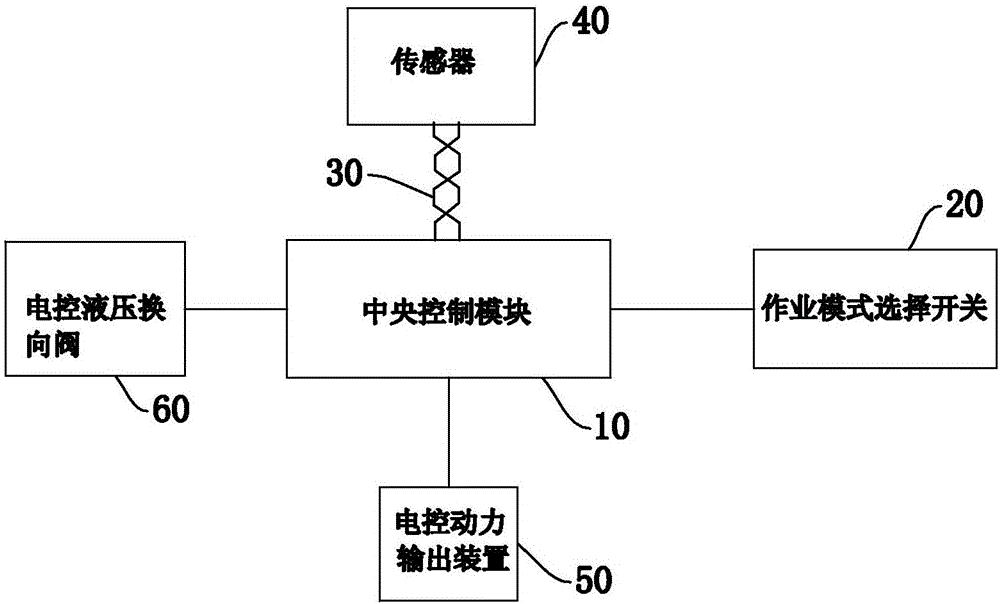

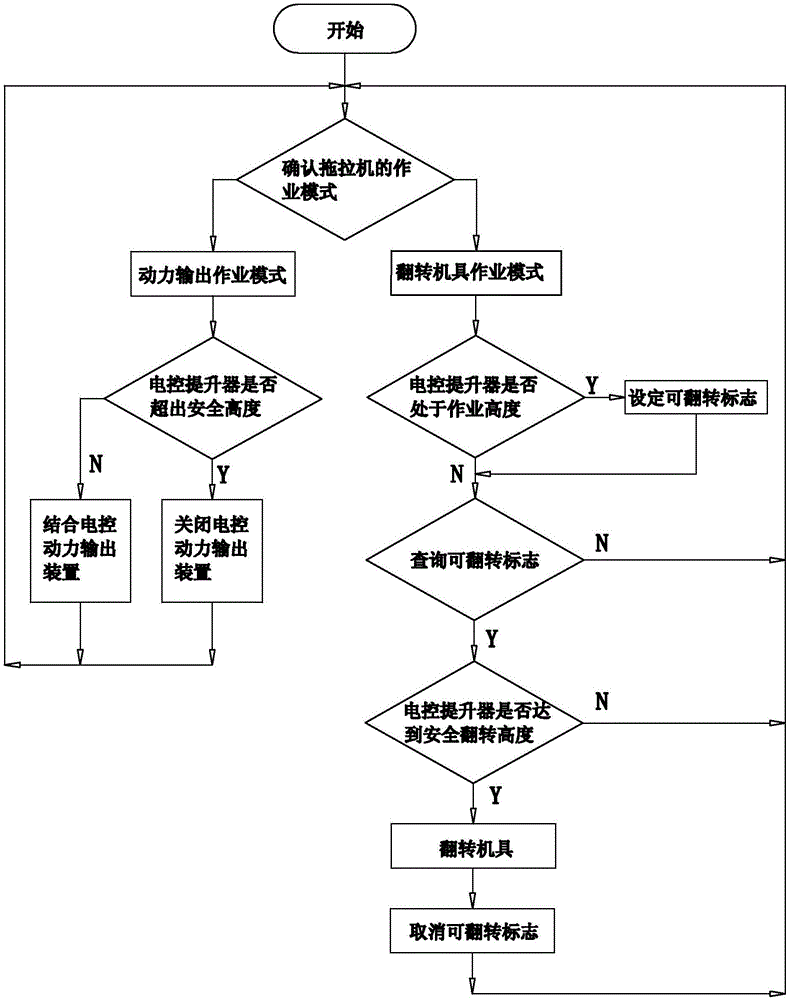

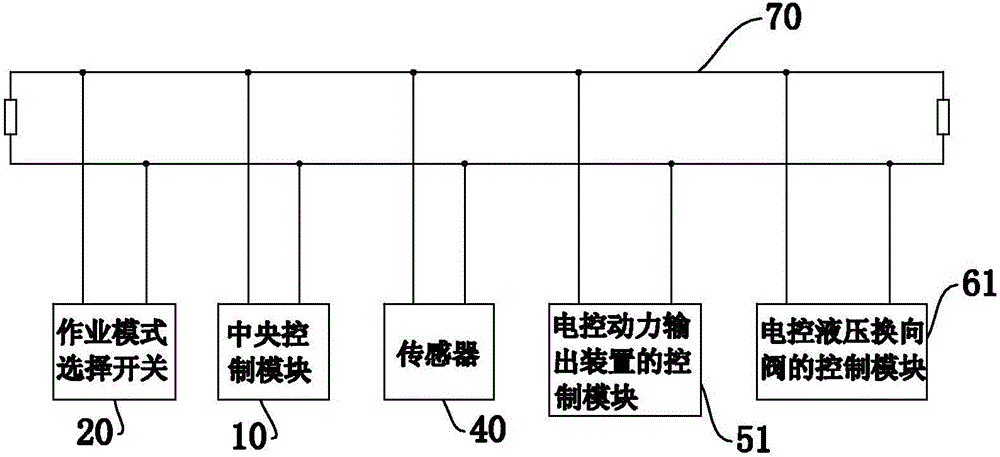

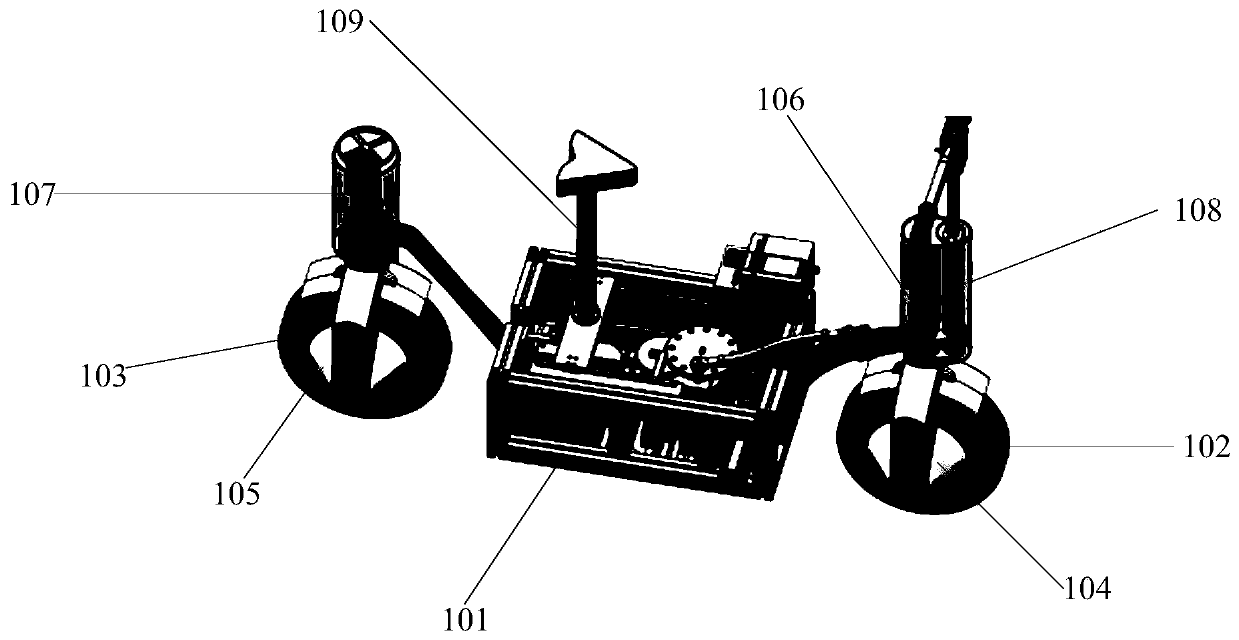

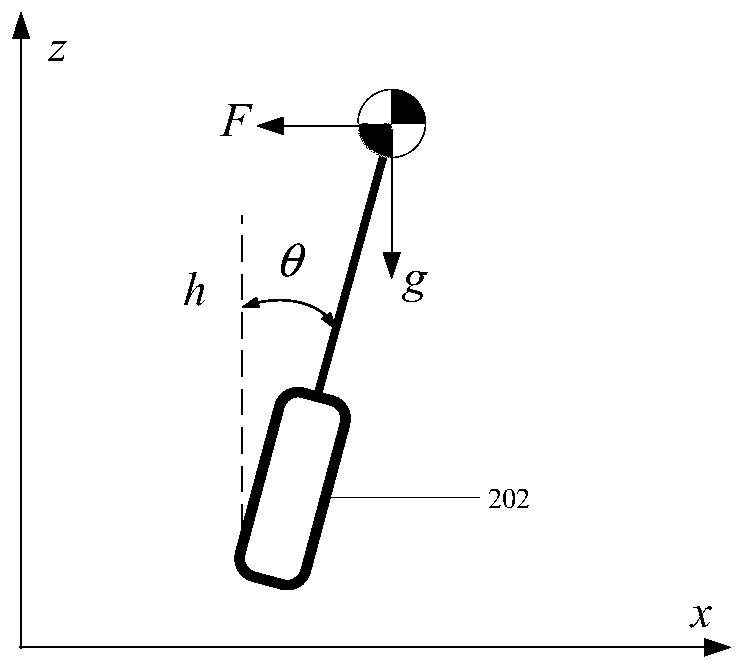

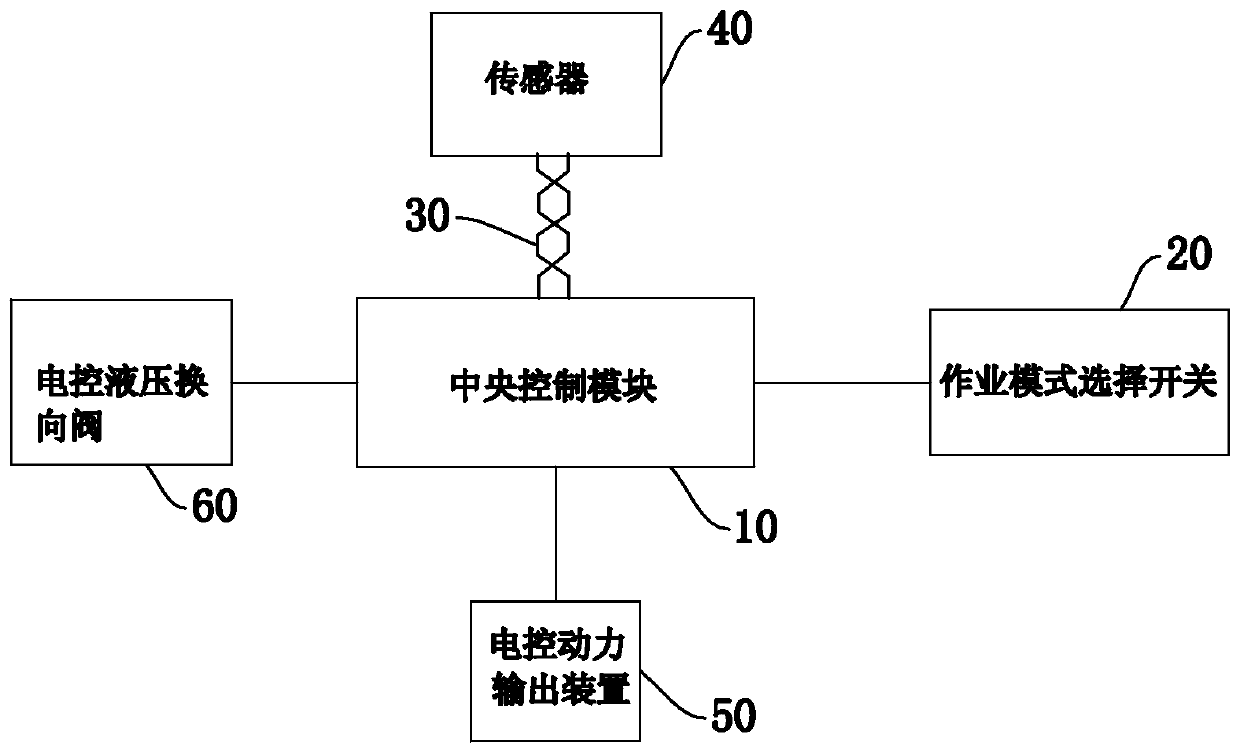

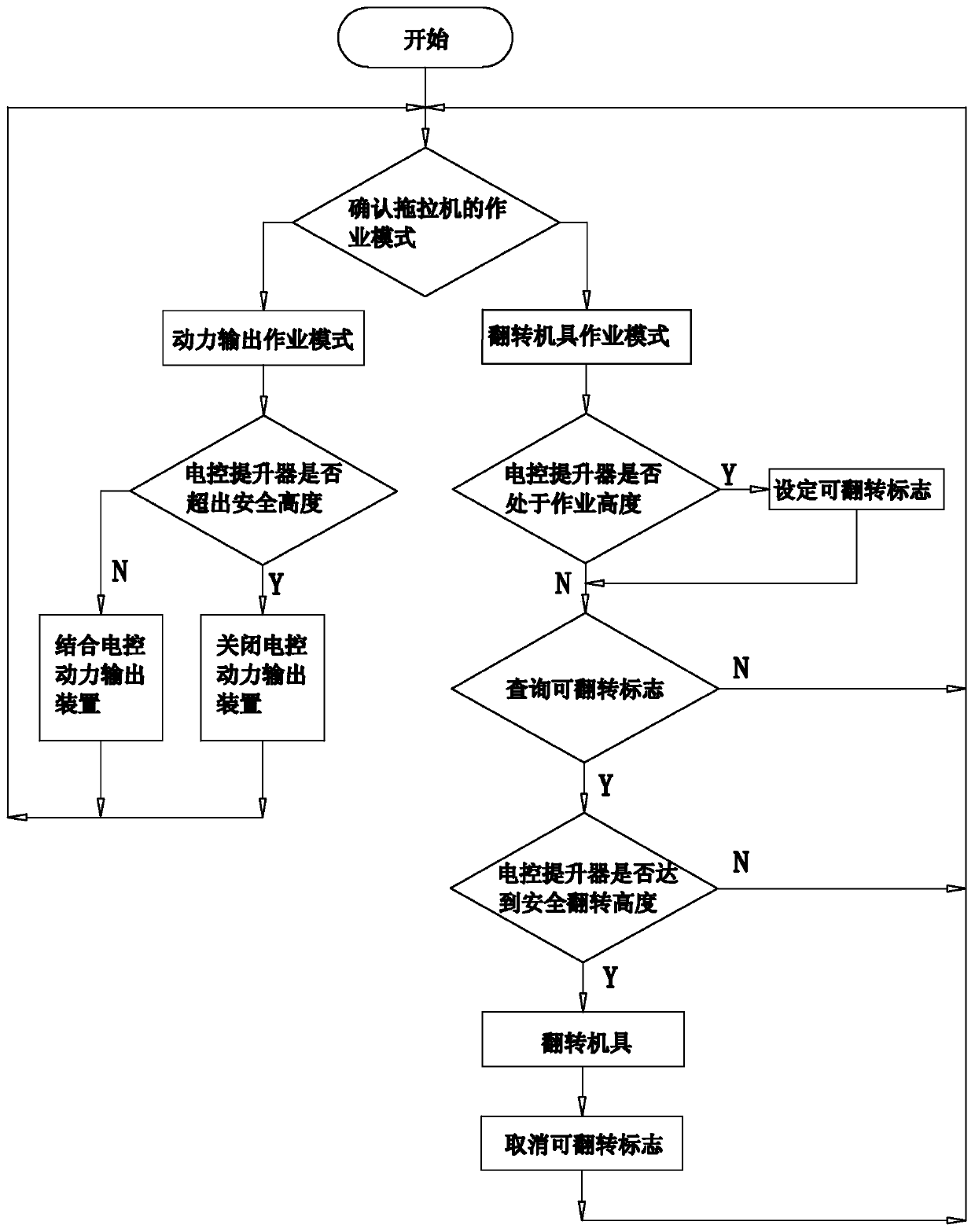

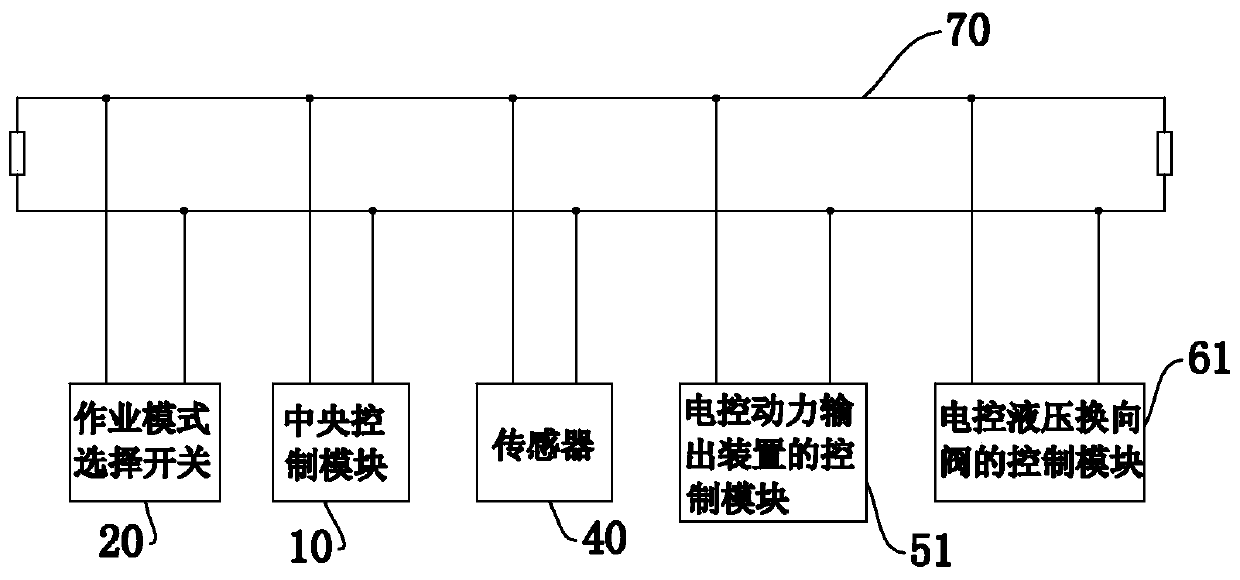

Tractor tool management and control method

ActiveCN106717212AEasy to operateAvoid damageAgricultural machinesAdjusting devicesControl powerElectronic control system

The invention discloses a tractor tool management and control method, and belongs to the technical field of tractors. The method is used for controlling an electronic control power output device and an electronic control hydraulic reverse valve on the basis of an electronic control system and height data of an electronic control lifter. The method comprises the following steps that an operation mode selection switch is operated, a power output operation mode is activated, when the electronic control lifter exceeds the preset power output safe height, the electronic control power output device is powered off, and when the electronic control lifter is in a safe height range, the electronic control power output device is combined; the operation mode selection switch is operated, a turning tool operation mode is activated, and when the electronic control lifter rises to the safe turning height from the operation height range, the electronic control hydraulic reverse valve conducts reversing, and then a turning tool conducts turning. According to the tractor tool management and control method, the power output device and the turning tool are automatically powered off or combined on the basis of the height of the lifter, manual control is not needed, operation of a manipulator is simplified, the operation efficiency is improved, and damage caused by misoperation of the manipulator to the tool or a tractor power output shaft is avoided.

Owner:LOVOL HEAVY IND

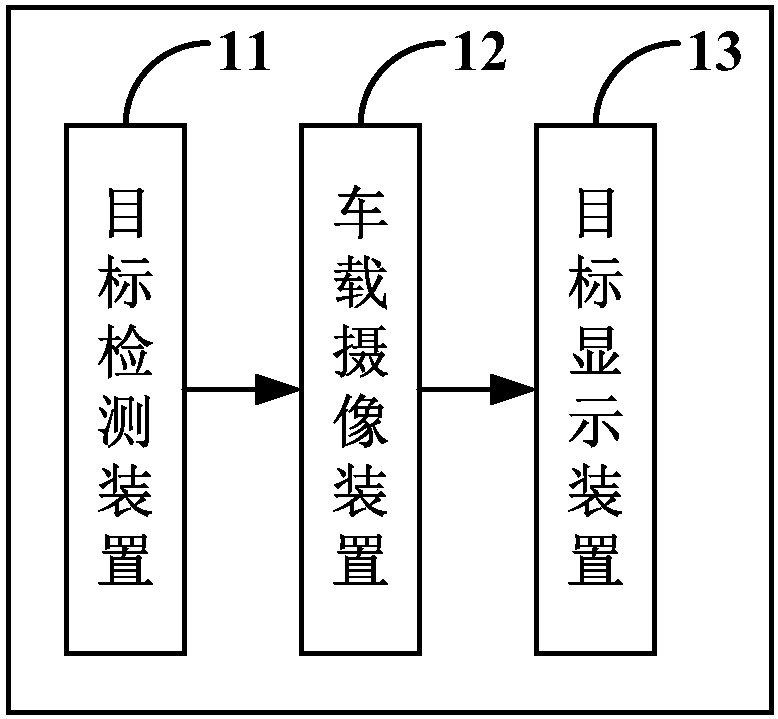

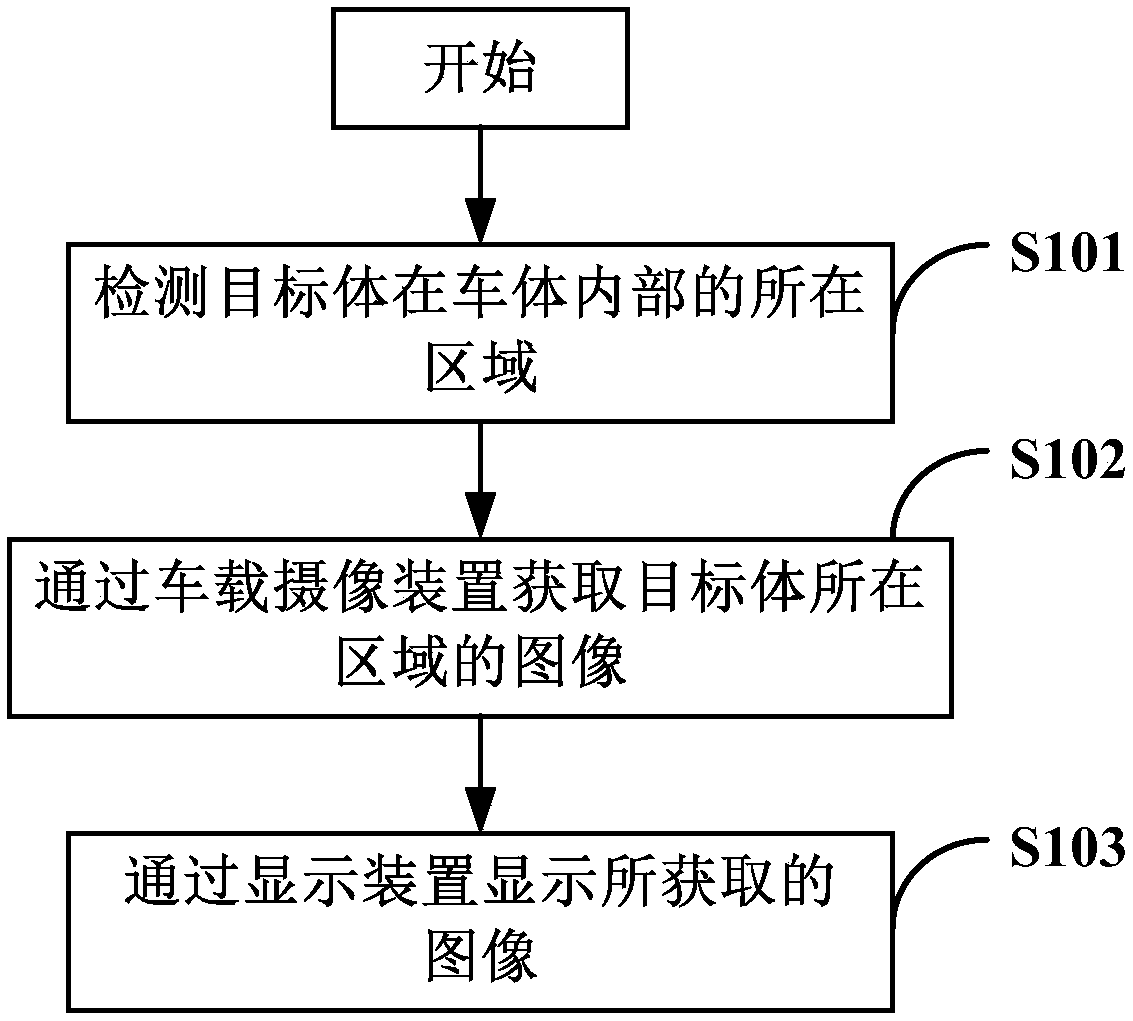

Monitoring system and method for target body in vehicle, and vehicle

InactiveCN108177611ANo manual controlsSimple and fast operationTelevision system detailsPedestrian/occupant safety arrangementIn vehicleDisplay device

The invention relates to the technical field of monitoring, and particularly provides a monitoring system and method for a target body in a vehicle, and the vehicle comprising the system. The technical problem of how to enable drivers to accurately and conveniently monitor the state of children is solved. For the purpose, in the monitoring system, a target detection device can automatically detectthe area where the target body is located in a vehicle body, and the image of the area is displayed through a target display device, wherein the target display device is arranged in a central controlof the vehicle. The monitoring method can also control the target display device to automatically display the image of the area where the target object in the vehicle is located. Based on the technical scheme, drivers can monitor the movement state of the target body, such as children, in real time without rotating the body or adjusting rearview mirrors.

Owner:NIO ANHUI HLDG CO LTD

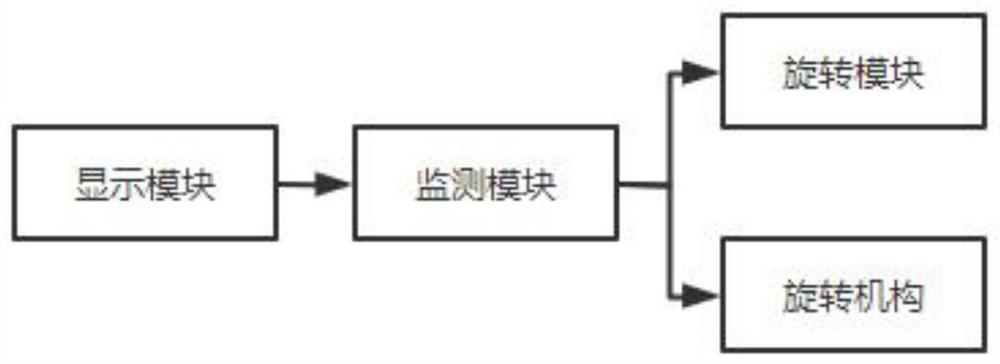

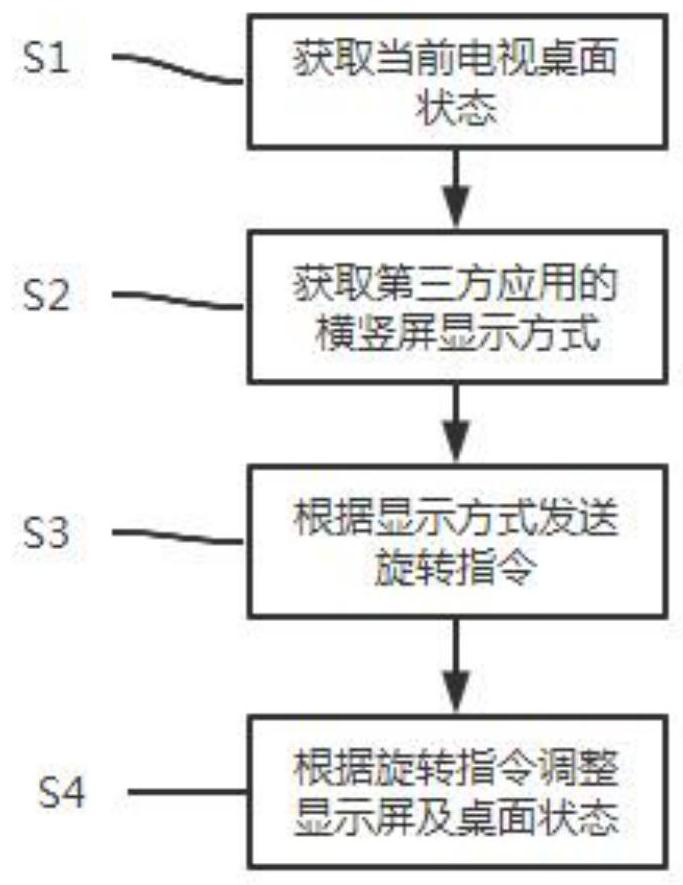

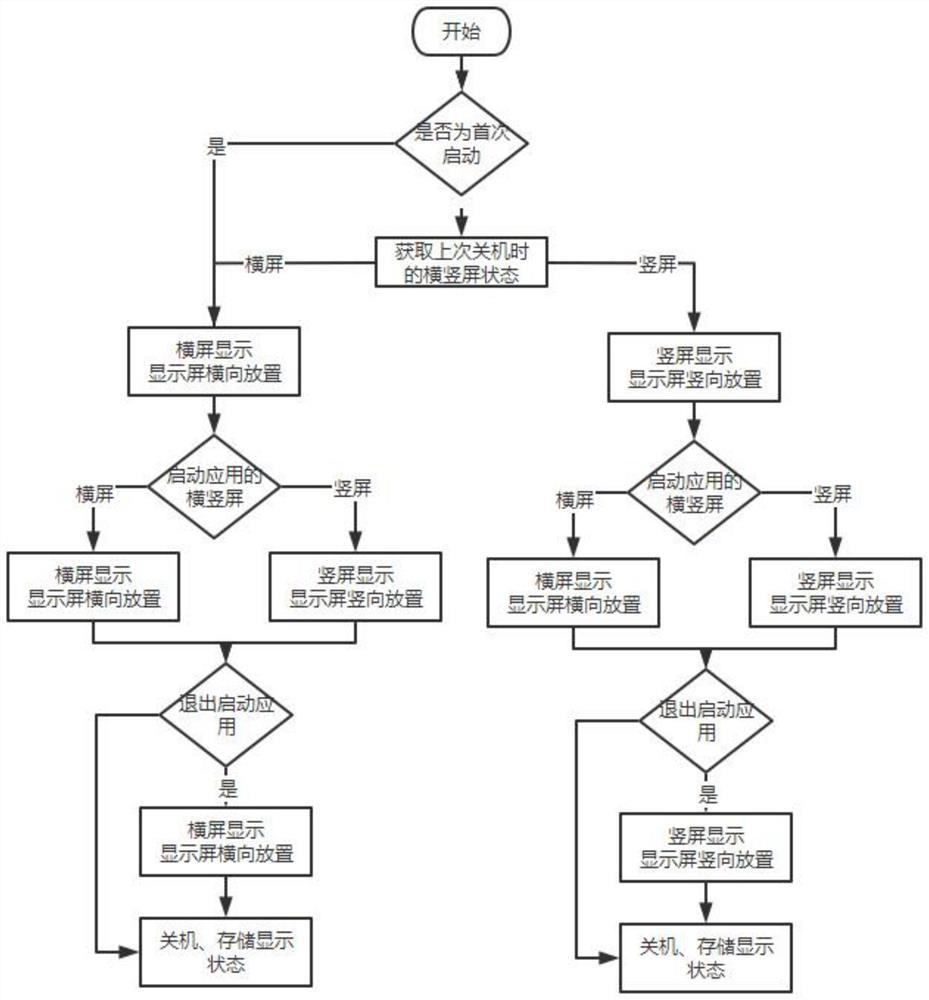

Intelligent rotary television desktop and horizontal and vertical screen management and control method thereof

InactiveCN112104916AImplement auto-rotationNo manual controlsSelective content distributionComputer hardwareThird party

The invention relates to the field of television desktop display, in particular to an intelligent rotary television desktop, which aims at solving the problem that television display cannot be automatically rotated and adapted according to a display mode of a starting application, and comprises a display module, a monitoring module for monitoring the display mode of the starting application and arotating module for switching the display mode according to a monitoring result, and the monitoring module controls the rotation of the rotating mechanism according to a monitoring result; the invention discloses an intelligent rotary television horizontal and vertical screen management and control method. The method comprises the steps of S1, obtaining a current television desktop state; S2, obtaining a display mode of a third-party application; S3, sending a rotation instruction; and S4, adjusting the placement direction and the desktop state of the display screen according to the rotation instruction. By adopting the mode, horizontal and vertical screen rotation and horizontal and vertical screen display of the television display screen are automatically adjusted according to the horizontal and vertical screen display mode of the starting application, and a regulation and control instruction does not need to be manually input.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

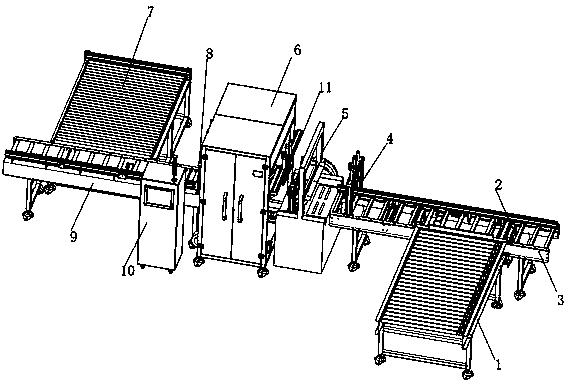

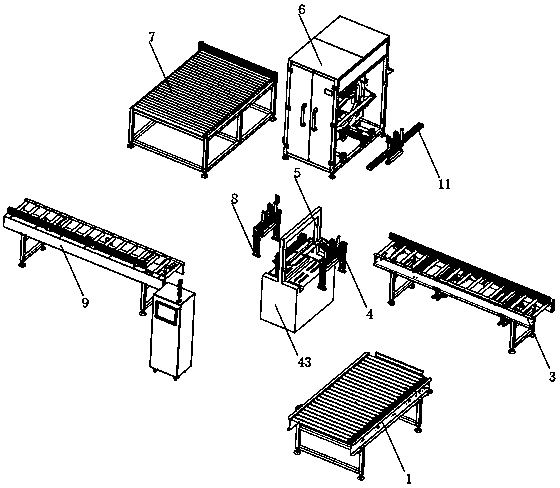

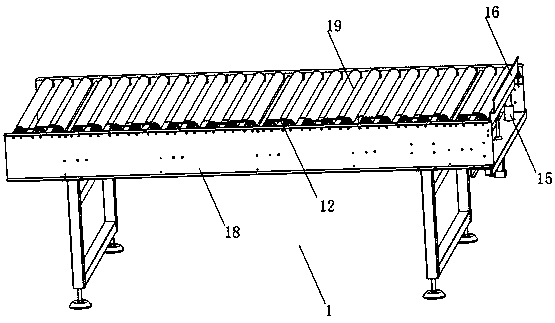

Bundling and sealing adhesive machine

InactiveCN111099085AImprove efficiencyImprove accuracyWrapper twisting/gatheringPackaging automatic controlAdhesive beltMechanical engineering

The invention discloses a bundling and sealing adhesive machine. The bundling and sealing adhesive machine comprises a bundling belt mechanism and a sealing adhesive belt mechanism. The sealing adhesive belt mechanism is installed at one end of the bundling belt mechanism. A discharging conveying mechanism is installed at the end, away from the bundling belt mechanism, of the sealing adhesive beltmechanism. A finished product carrying platform is installed on one side of the discharging conveying mechanism. A material inlet conveying mechanism is installed at the end, away from the sealing adhesive belt mechanism, of the bundling belt mechanism. A feeding conveying mechanism is installed on one side of the material inlet conveying mechanism. The feeding conveying mechanism comprises a feeding frame. The material inlet conveying mechanism comprises a material inlet frame. The discharging conveying mechanism comprises a discharging frame. When a box body moves, a side plate and a lifting conveying mechanism can adjust the position of the box body so that the box body can accurately enter the bundling belt mechanism and the sealing adhesive belt mechanism, and therefore a bundling belt and a sealing adhesive can be accurately installed at the outer portion of the box body. In addition, after the bundling belt is installed, automatic detection can be conducted, it is ensured thatthe bundling belt is installed successfully, and the phenomenon of omission of the bundling belt is avoided.

Owner:佛山市和为上自动化包装设备有限公司

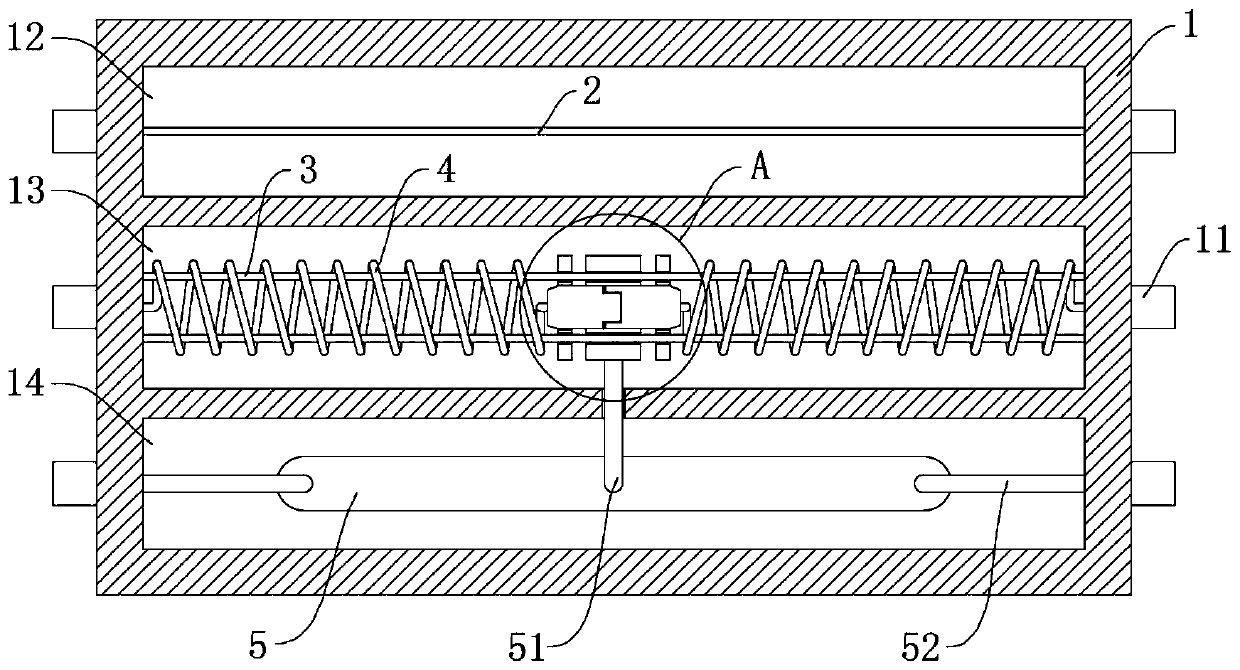

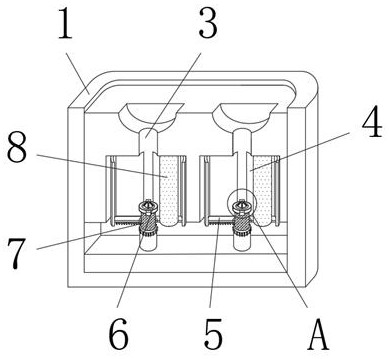

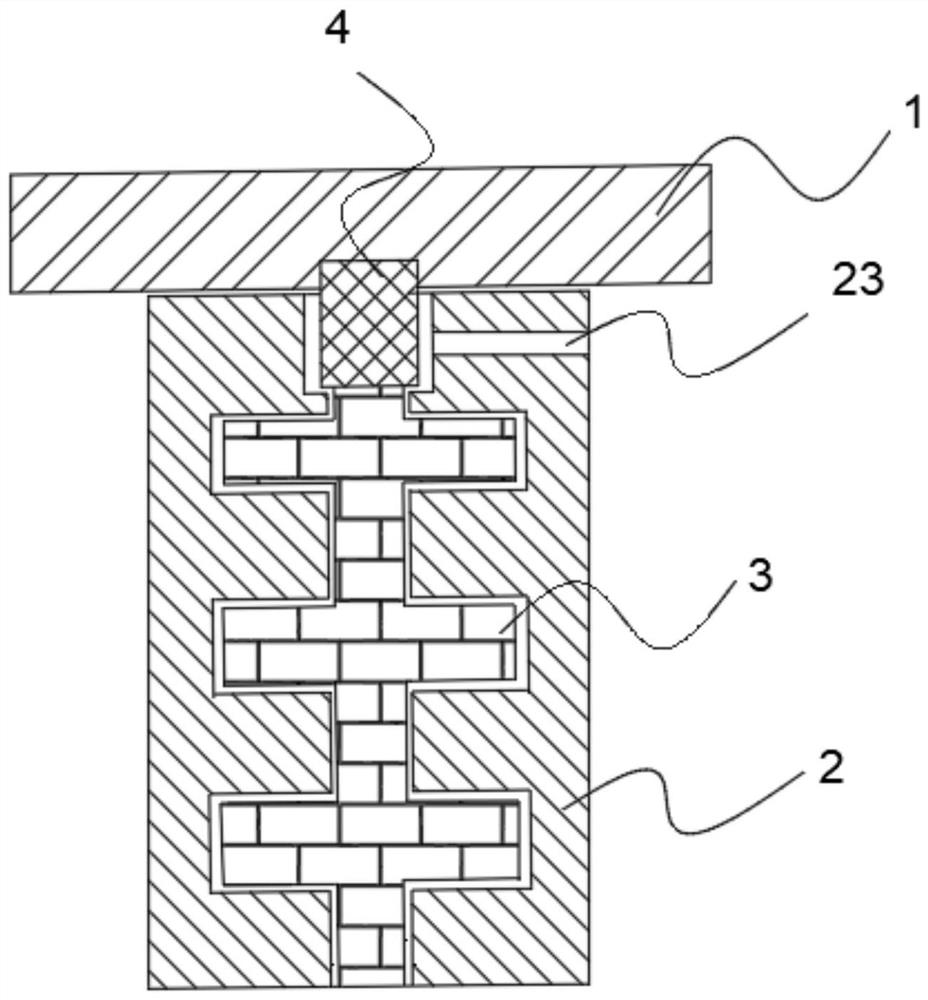

Short-circuit protection device

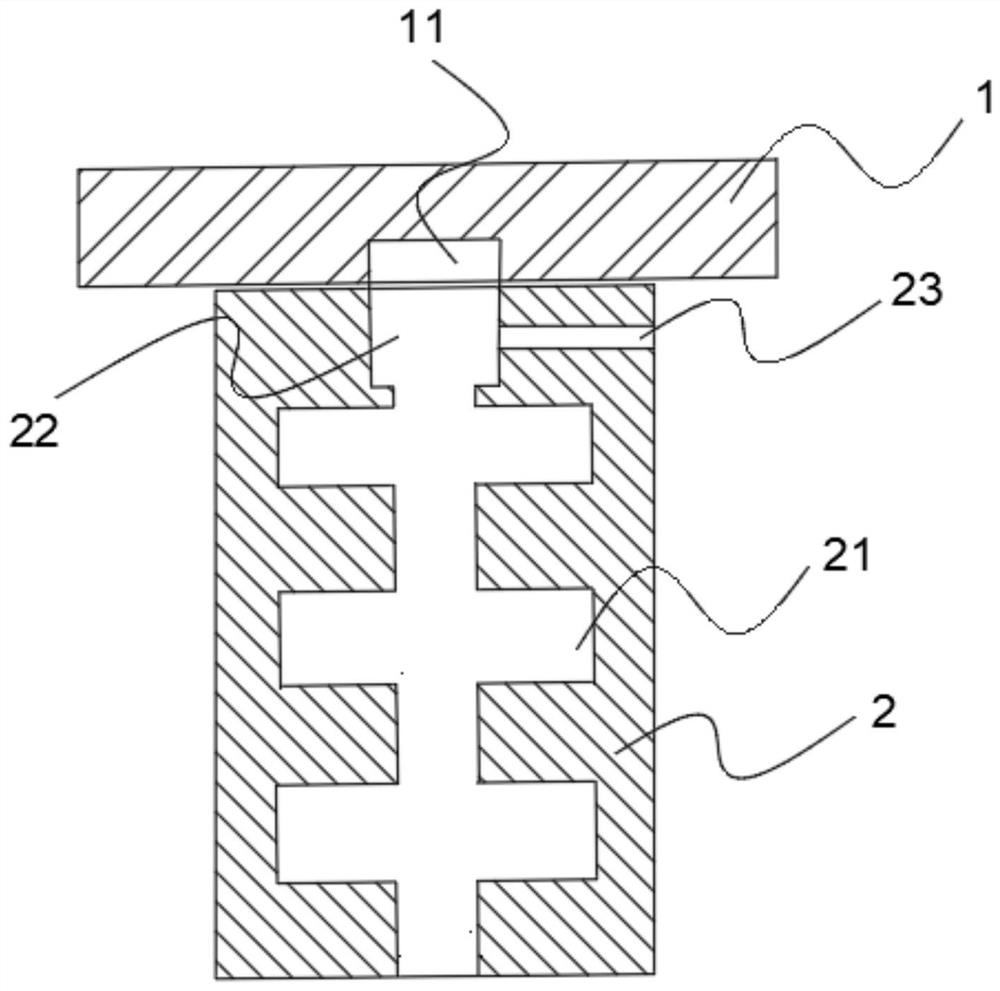

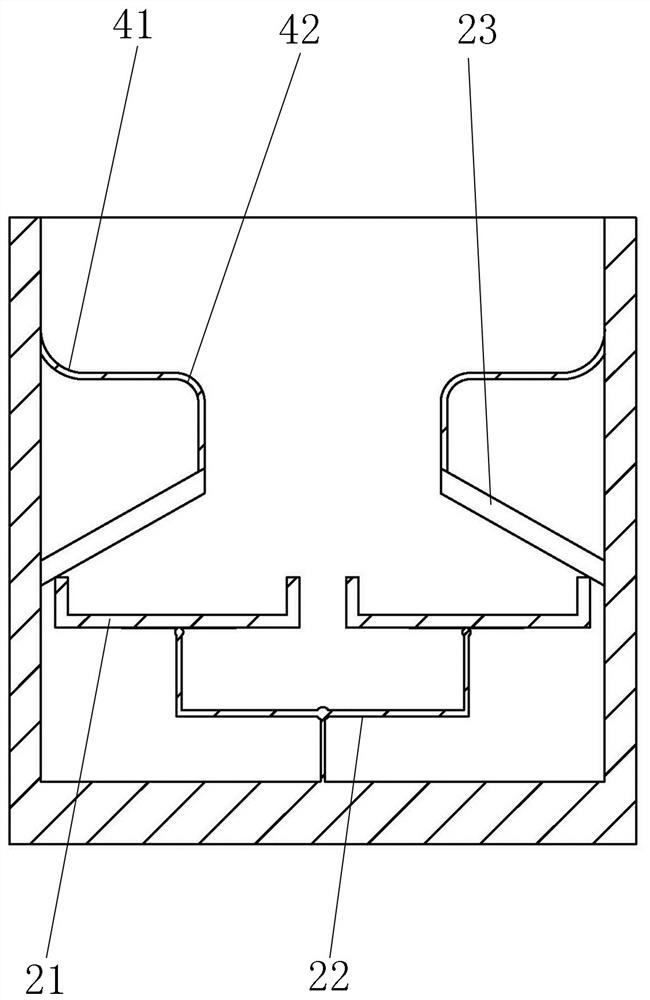

ActiveCN111477478AAvoid damageImprove electricity safetyContact operating partsSwitch power arrangementsStructural engineeringShort circuit protection

The invention discloses a short-circuit protection device. The short-circuit protection device includes a housing, a zero line cavity, a protection cavity and a grounding cavity are formed in the housing from top to bottom. A zero line cavity is formed in the housing, a zero line is installed in the zero line cavity, a grounding piece is installed in the grounding cavity, a protection wire and twosymmetrical ground wires are installed on the grounding piece, three pairs of binding posts are symmetrically installed on the side wall of the housing, two sliding rods are symmetrically installed in the protection cavity, and two spring wires are jointly and symmetrically wound on the two sliding rods. According to the short-circuit protection device, the magnetic field of the spring wire is enhanced by increasing the short-circuit current to contract and disconnect the magnetic plug and the magnetic sleeve head; after the short-circuit current is eliminated, the magnetic field is weakened,so that the spring wire rebounds to push the magnetic plug and the magnetic sleeve head to connect a circuit, the short-circuit self-recovery function is realized, and the safety of short-circuit protection is improved through a protection ring.

Owner:深圳市中创电测技术有限公司

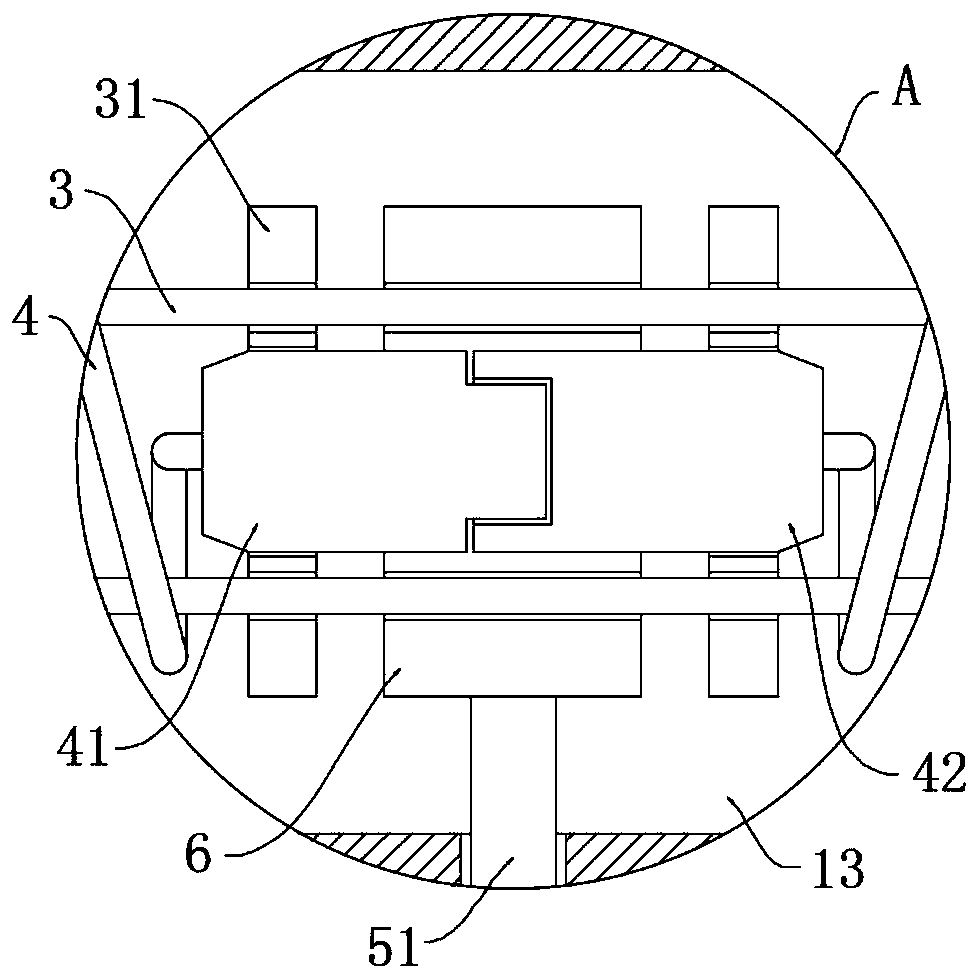

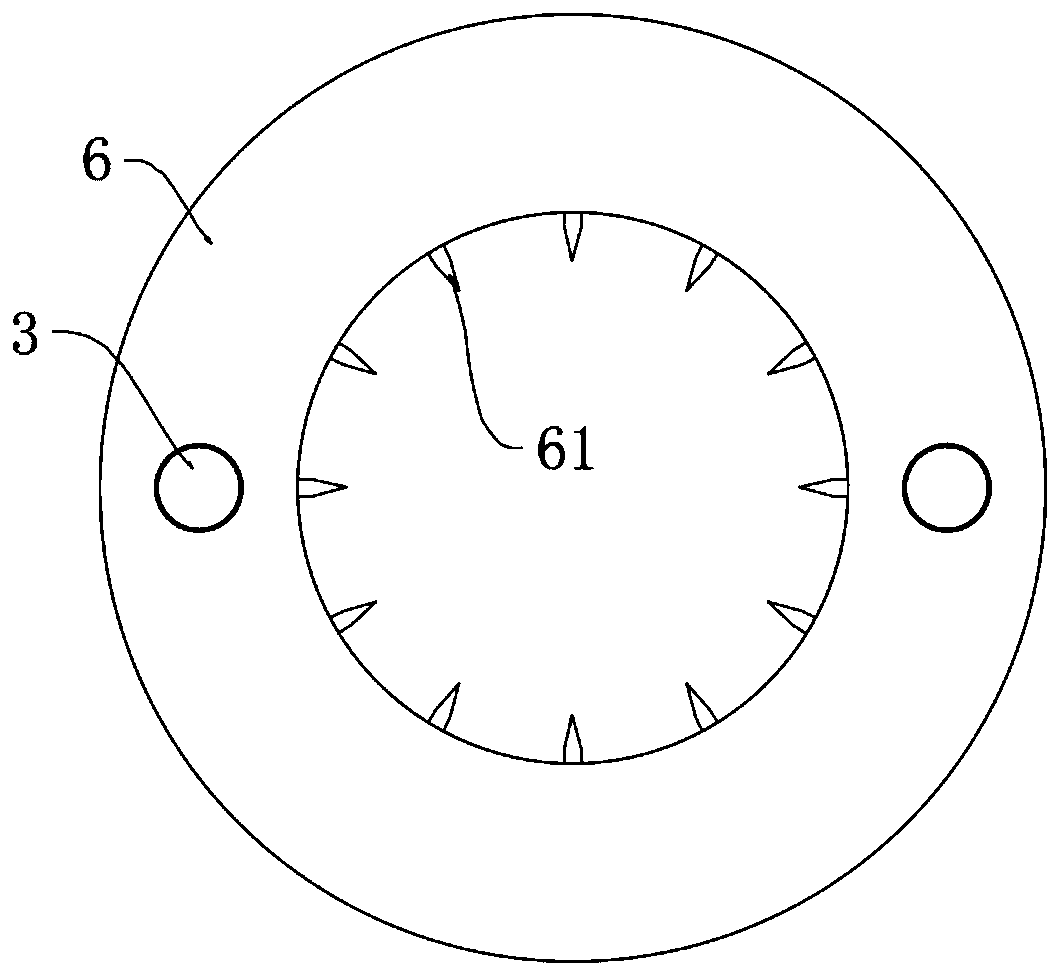

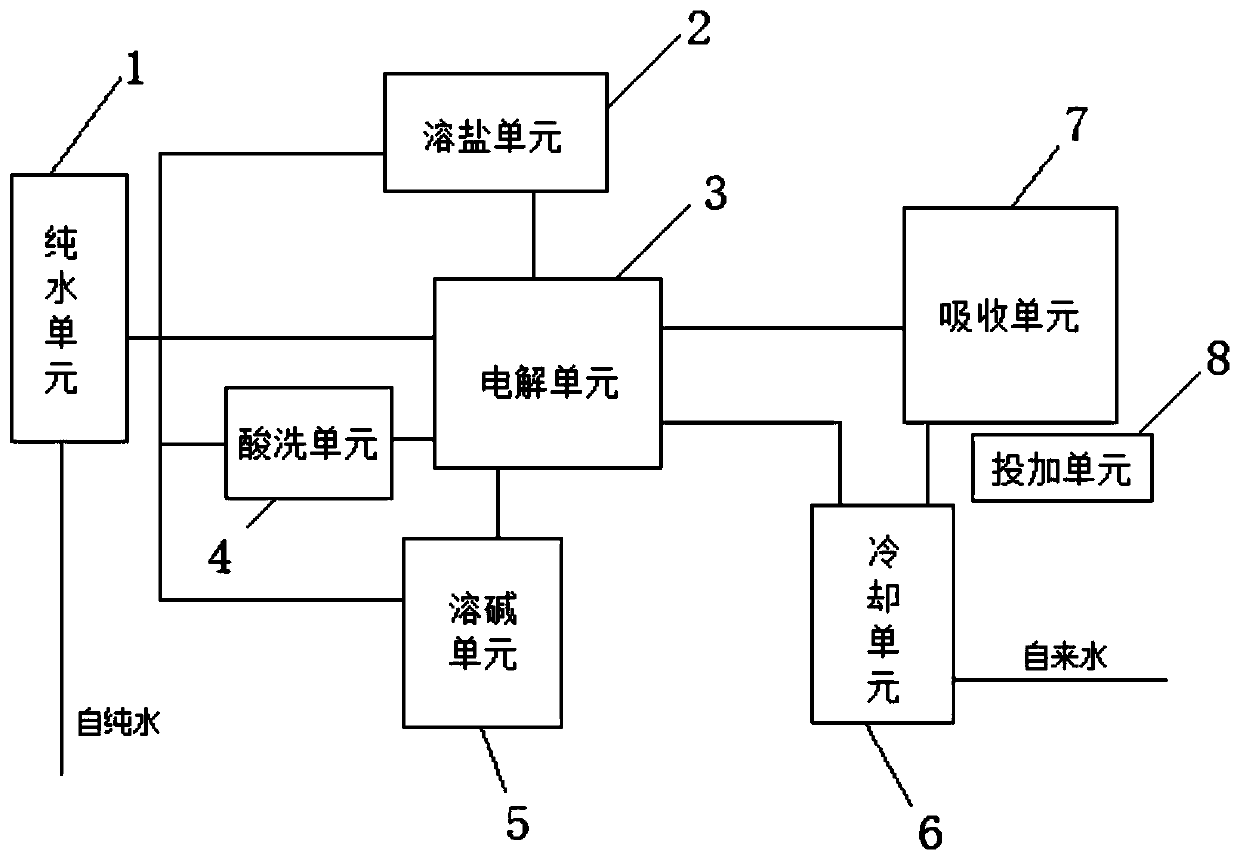

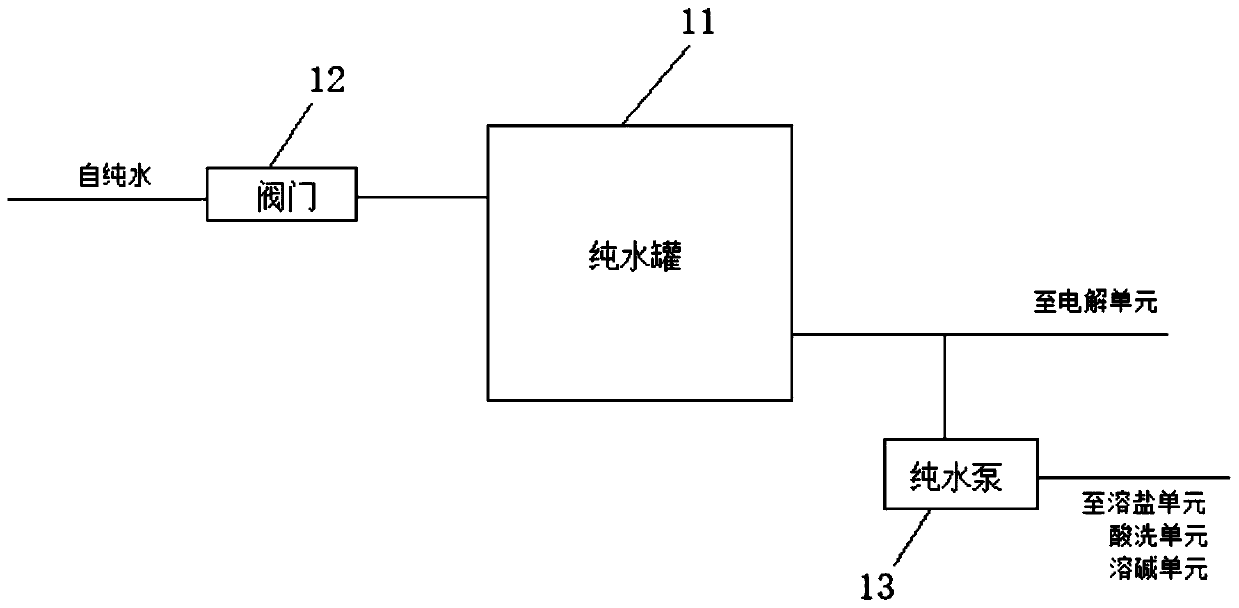

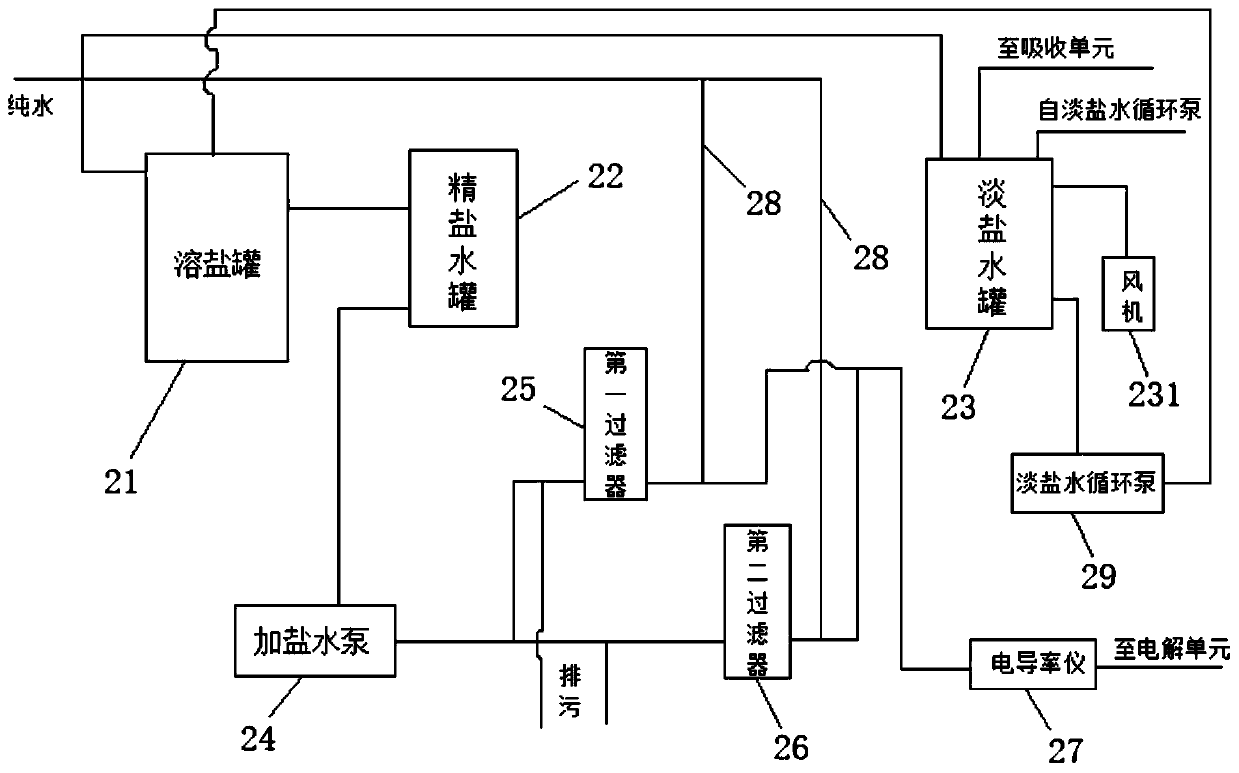

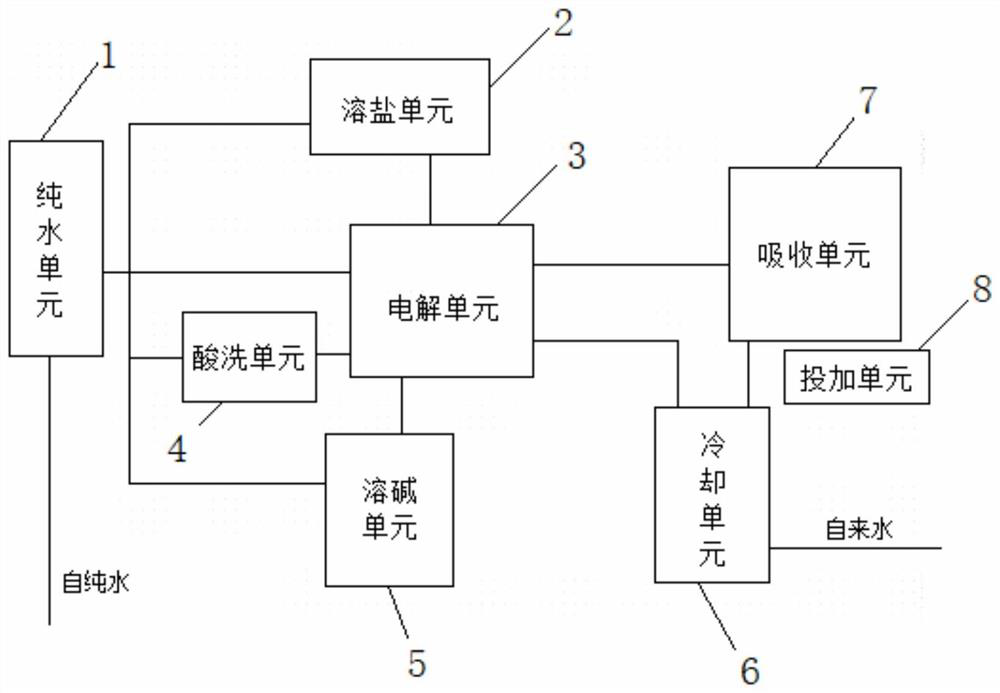

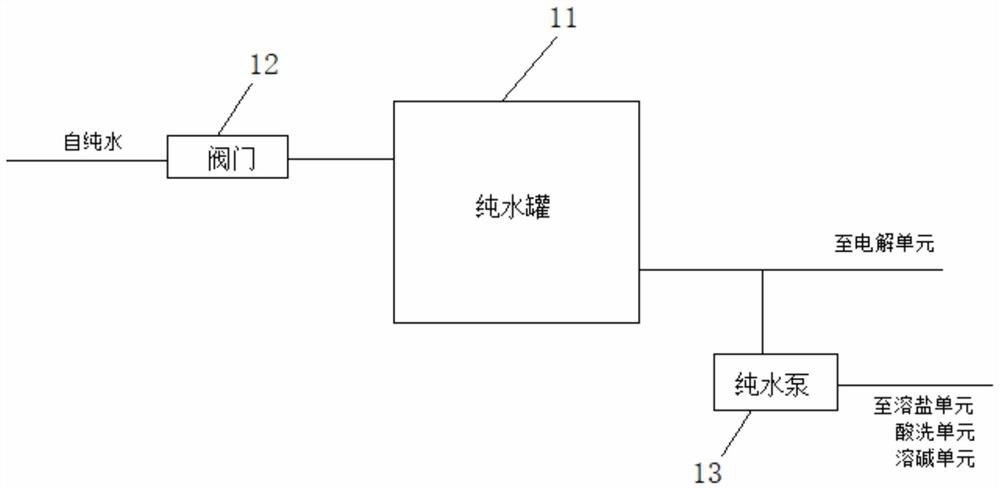

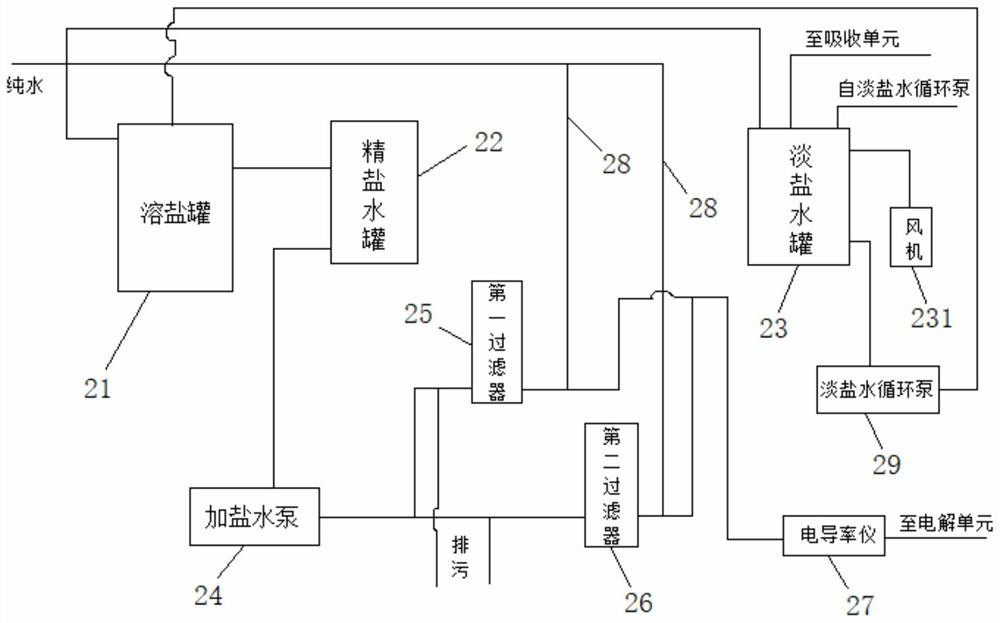

Full-automatic high concentration sodium hypochlorite generating system

The invention provides a full-automatic high concentration sodium hypochlorite generating system, comprising a water purifying unit, a salt dissolving unit, an electrolytic unit, an acid pickling unit, an alkali dissolving unit, a cooling unit, an absorption unit and a feeding unit, wherein the water purifying unit is connected with the salt dissolving unit, the electrolytic unit, the acid pickling unit and the alkali dissolving unit; the electrolytic unit is connected with the salt dissolving unit, the acid pickling unit, the alkali dissolving unit, the cooling unit and the absorption unit; the absorption unit is connected with the cooling unit; the water purifying unit, the salt dissolving unit, the electrolytic unit, the acid pickling unit, the alkali dissolving unit, the cooling unit,the absorption unit and the feeding unit are controlled by means of a programmable logic controller (PLC) unit so as to automatically execute actions of water replenishing, salt dissolving, washing, acid pickling, circulating, electrolyzing and discharging. The full-automatic high concentration sodium hypochlorite generating system can realize full automatic production of a sodium hypochlorite solution under the control of a PLC.

Owner:FUJIAN HADA INTELLIGENCE TECH CO LTD +1

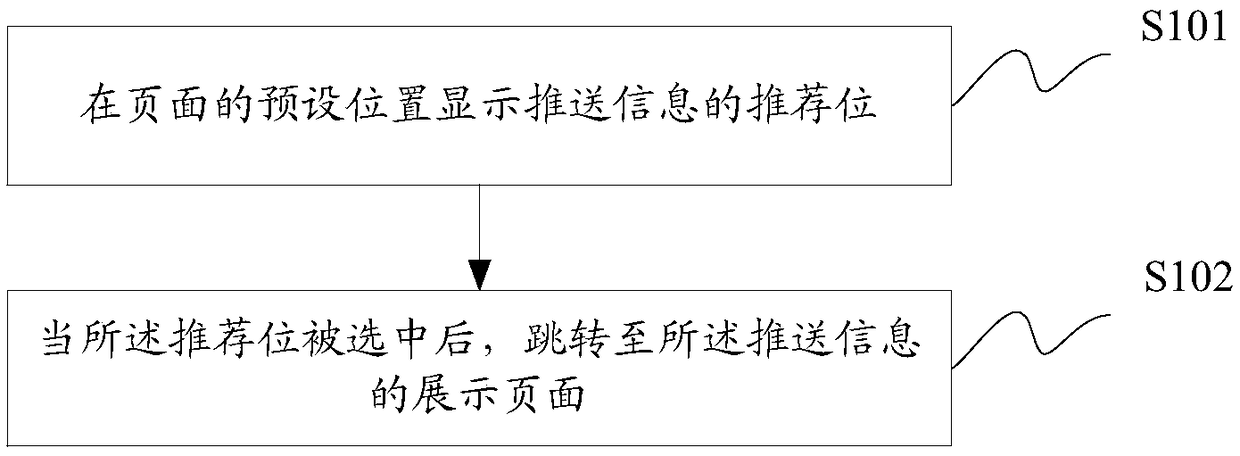

Information display and pushing method and device

InactiveCN108881443ANo manual controlsTransmissionSelective content distributionComputer terminalComputer science

Owner:JUHAOKAN TECH CO LTD

Rotatable LED lamp holder

PendingCN109519896AEasy to disassembleEasy to installLighting support devicesSemiconductor devices for light sourcesEngineeringLED lamp

The invention discloses a rotatable LED lamp holder. The rotatable LED lamp holder comprises an installation base, a left sleeve, a right sleeve and a rotary base, wherein the left sleeve and the right sleeve are of a semi-annular barrel-shaped structure separately, and have the same dimensions; the left sleeve is fixedly bonded onto the upper end surface of the installation base; knobs are arranged at parts close to the two ends of the right sleeve, at the outer side of the top end of the left sleeve; a rotary rod vertically penetrating into the left sleeve is fixedly bonded to the bottom endof each knob; a first bevel gear fixedly sleeves the bottom end of each rotary rod in the left sleeve; each first bevel gear is in engagement connection with a second bevel gear; and a transversal screw rod is inserted into each second bevel gear through a thread, and one end of each transversal screw rod penetrates out of the vertical side surface of the left sleeve, and is inserted into a thread hole in the vertical side surface of the right sleeve. According to the rotatable LED lamp holder, during rotation for a lamp body, detachment and installation for a whole lamp holder structure arefacilitated, and overall maintenance and detection are facilitated.

Owner:XUZHOU ATP ELECTRONICS

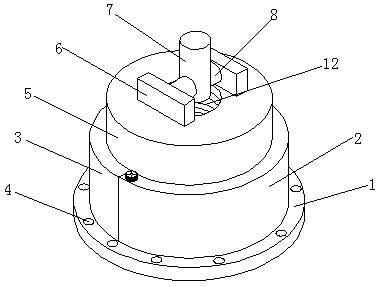

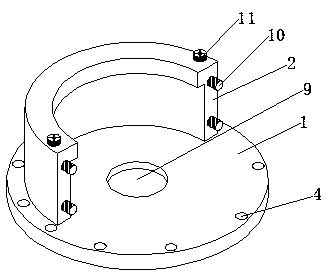

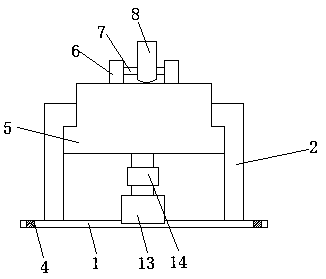

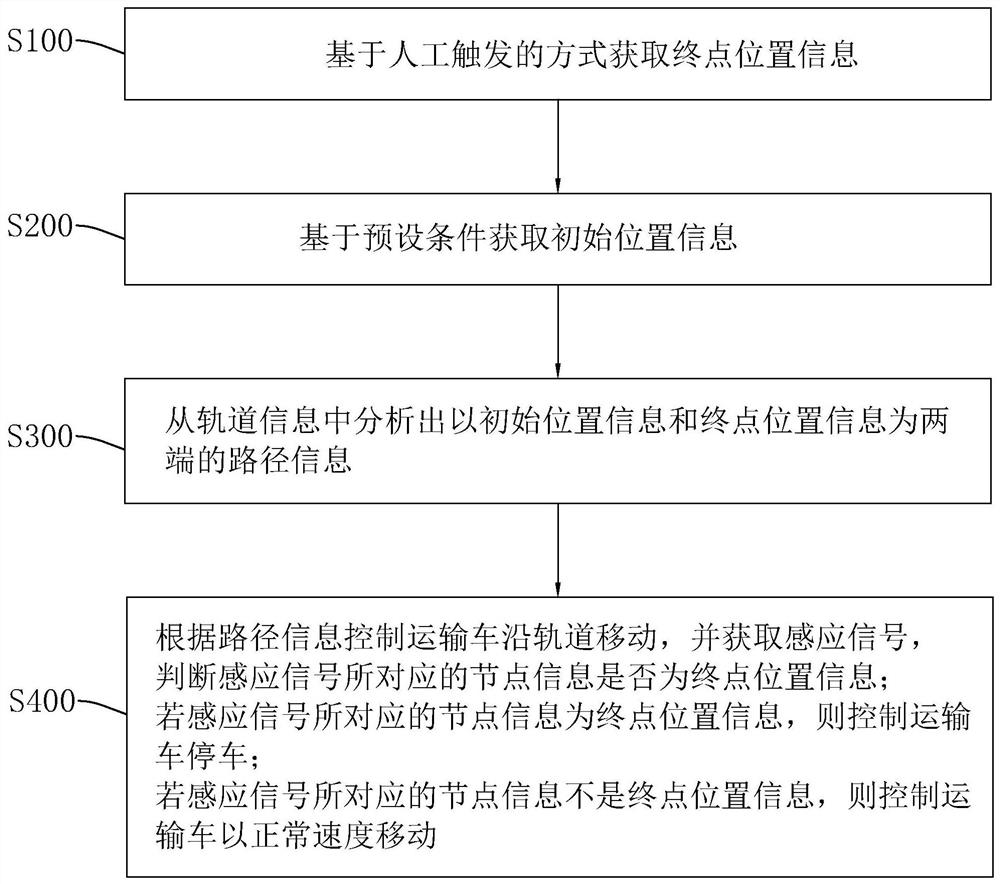

Automatic control method and system of rail transport vehicle and storage medium

PendingCN113885530AAvoid collisionAutomatic control intelligencePosition/course control in two dimensionsVehiclesAutomatic controlAutomotive engineering

The invention discloses an automatic control method and system for a rail transport vehicle and a storage medium. The automatic control method comprises the following steps of: acquiring final position information based on a manual triggering mode; acquiring initial position information based on a preset condition; analyzing path information with the initial position information and the final position information as the two ends from track information; acquiring an induction signal; judging whether node information corresponding to the induction signal is the final position information or not; and if the node information corresponding to the induction signal is the final position information, controlling the transport vehicle to stop, and if the node information corresponding to the induction signal is not the final position information, controlling the transport vehicle to move at a normal speed. A worker only needs to input a final position to the transport vehicle to form the final position information, the transport vehicle automatically obtains the initial position information and plans the moving path, automatic moving of the transport vehicle is achieved, and the transport vehicle can automatically complete the parking action by sensing the node information at the final position.

Owner:HANGZHOU HAOSHENG ELECTRIC VEHICLES

Water quality monitoring system for swimming pool

InactiveCN104730220AReal-time online detectionAccurate measurementTesting waterElectricitySample water

The invention relates to a water quality monitoring system, and in particular relates to a water quality monitoring system for a swimming pool. The water quality monitoring system is electrically connected with a medicament feeding system and a sampling water measurement system; the medicament feeding system comprises a medicament bottle and a medicament feeding pump; the sampling water measurement system comprises a sampling tank and a colorimetric measurement unit positioned on the sampling tank; the colorimetric measurement unit is provided with a mixer and a self-calibration device; a medicament injection opening, a sampling water injection opening and a liquid outlet are formed in the mixer. The water quality monitoring system for the swimming pool can realize real-time online detection and full-automatic micro-computer control and can carry out auto parameter setting, liquid crystal digital displaying, temperature compensation and precise measurement; a plurality of parameters can be selected to realize simultaneous online monitoring and control; the operations of the medicament feeding system and a circulating water pump are configured into an interlocking device, and the manual control is not needed.

Owner:施周平

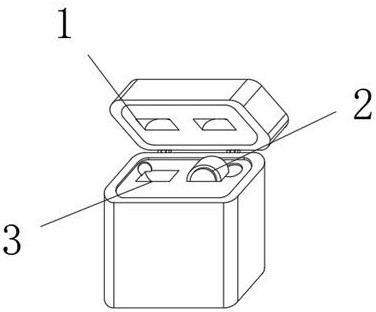

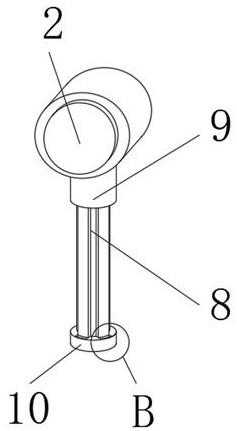

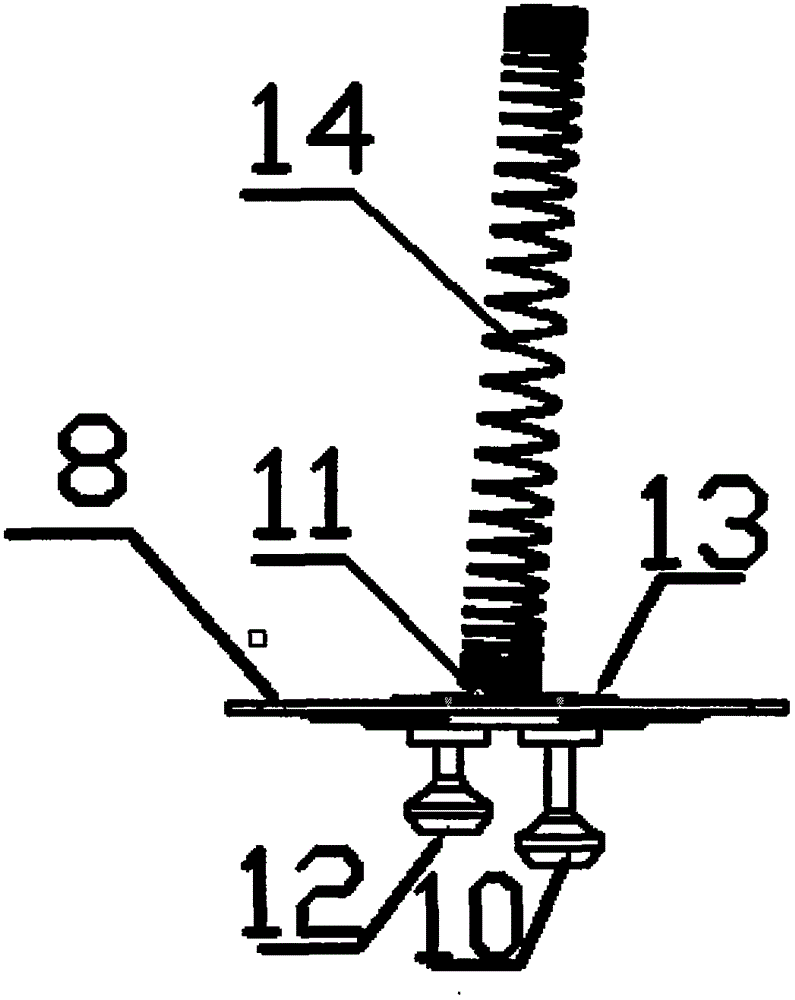

Bluetooth headset quick battery replacement structure and battery replacement method thereof

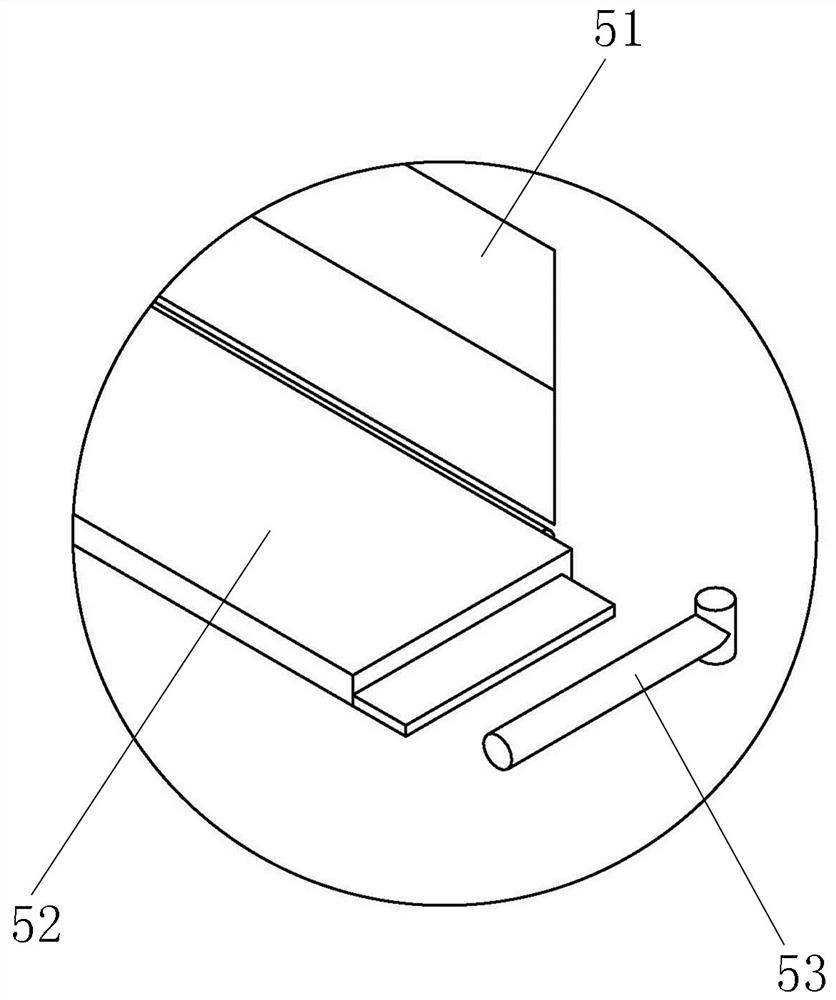

PendingCN113810815ANo window requiredNo manual controlsCharging attachments/accumulatorsComputer hardwareEmbedded system

The invention discloses a Bluetooth headset quick battery replacement structure and a battery replacement method thereof, and particularly relates to a Bluetooth headset quick battery replacement structure which comprises a headset and a headset bin for charging the headset, a headset groove attached to the headset is formed in the headset bin, a replaceable battery cell is assembled in the headset, a battery replacement groove is further formed in the headset bin and communicated with the headset groove, a battery replacement device used for replacing the replaceable battery cell in the headset is arranged in the battery replacement groove, a driving plate is connected to the middle of the battery replacement device in a driving mode, and the driving plate is slidably connected to the interior of the headset groove. According to the headset structure, the headset does not need to be put into the headset bin for continuous charging to cause the situation that the headset cannot be used during charging, and quick and efficiency battery replacement is performed for the headset so that the operation is convenient.

Owner:SHENZHEN SHENYU ELECTRONICS TECH CO LTD

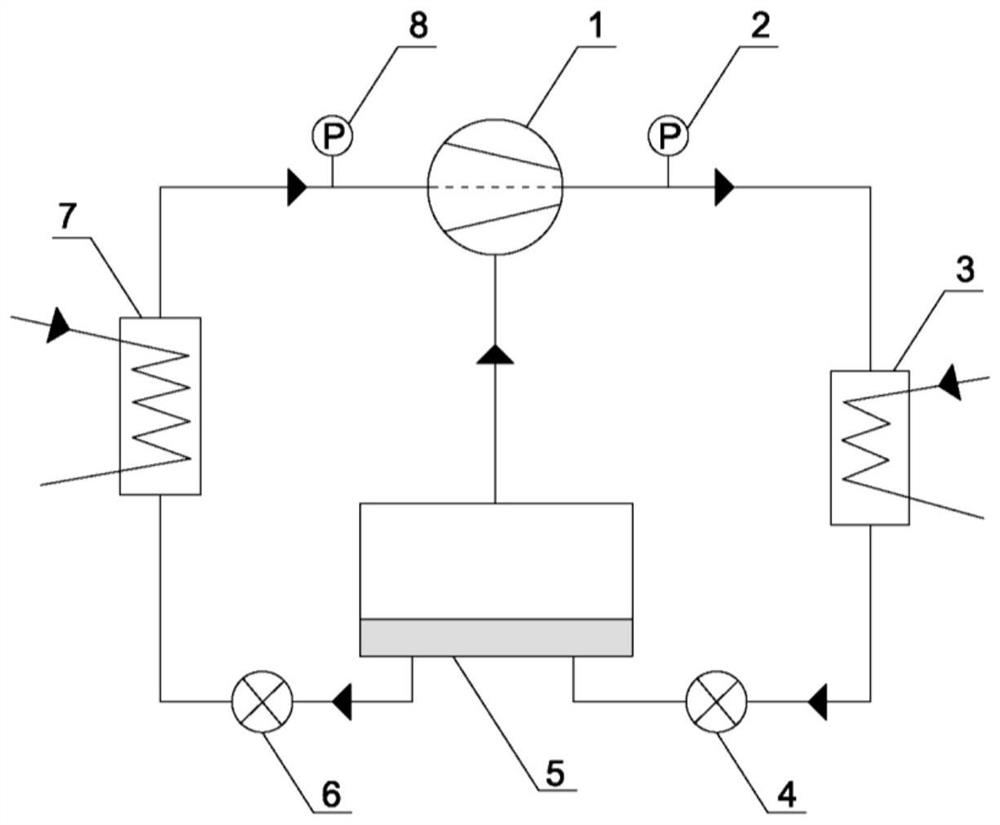

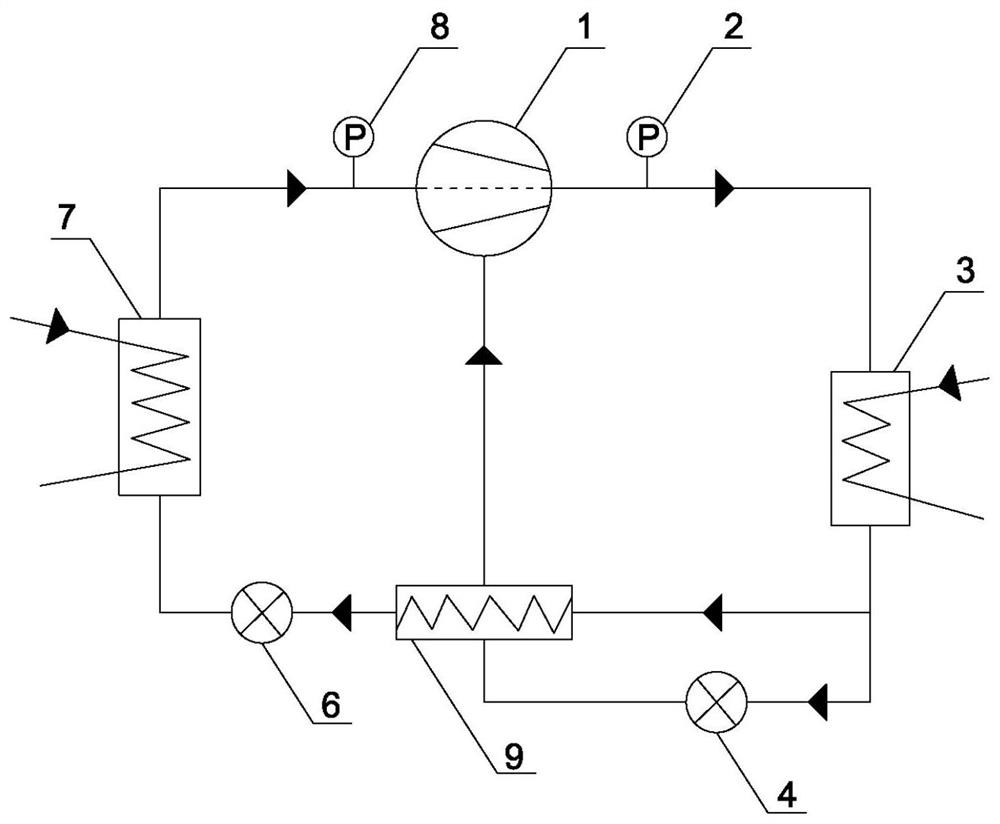

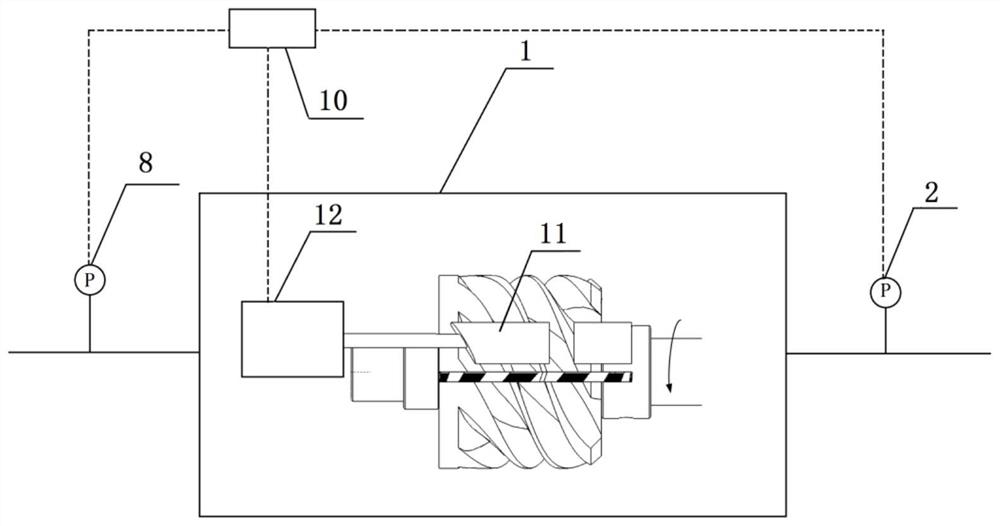

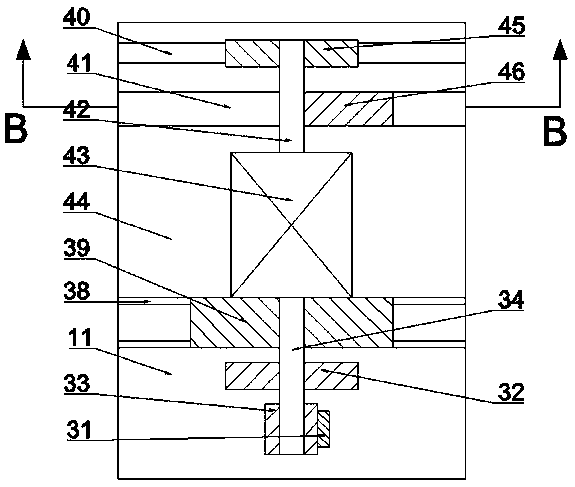

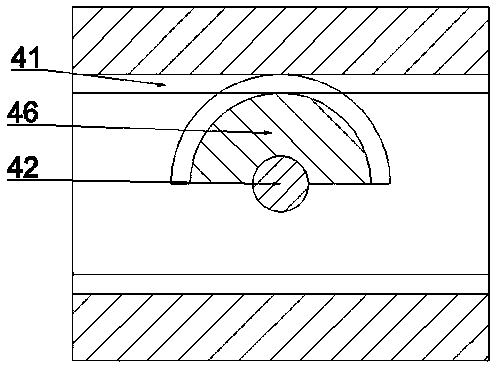

Single-screw refrigeration compressor heat pump system coupling air supply and composite slide valve

PendingCN112880215ASimple structureNo manual controlsCompression machines with non-reversible cycleRefrigeration safety arrangementRefrigeration compressorSpool valve

The invention discloses a single-screw refrigeration compressor heat pump system coupling air supply and a composite slide valve, and belongs to the technical field of compressors. The heat pump system aims to adjust the capacity and the internal volume ratio of a single-screw refrigeration compressor by utilizing the composite slide valve, and to increase the heating capacity of the heat pump system by utilizing air supply, and belongs to the field of fluid machinery. According to the system, air supply and the composite slide valve are coupled to realize air supply, and the variable internal volume ratio can be realized at the same time. Therefore, when the single-screw refrigeration compressor applying the coupled air supply and the composite slide valve is applied to the heat pump system, the system performance of the heat pump system can be improved in a low-temperature environment, and the overall power consumption of the heat pump system can be reduced under other working conditions deviating from the design working condition.

Owner:BEIJING UNIV OF TECH

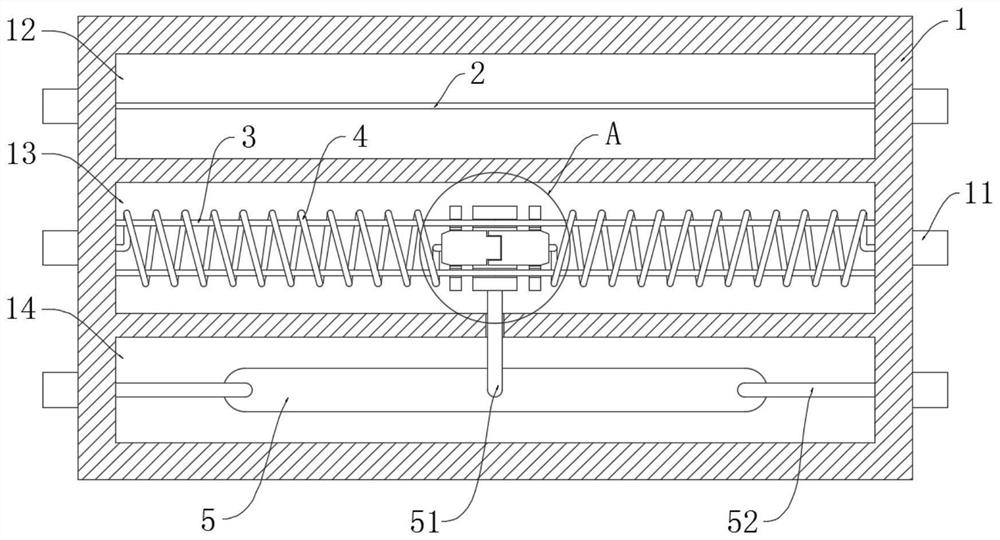

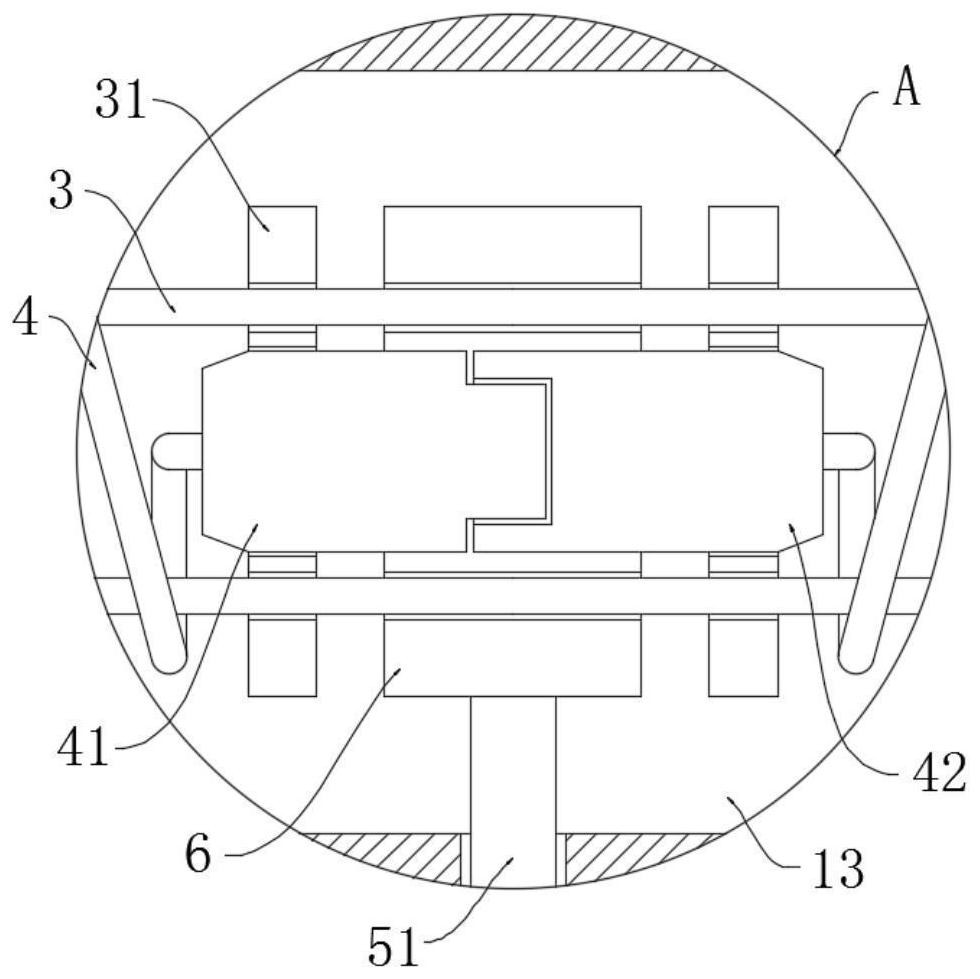

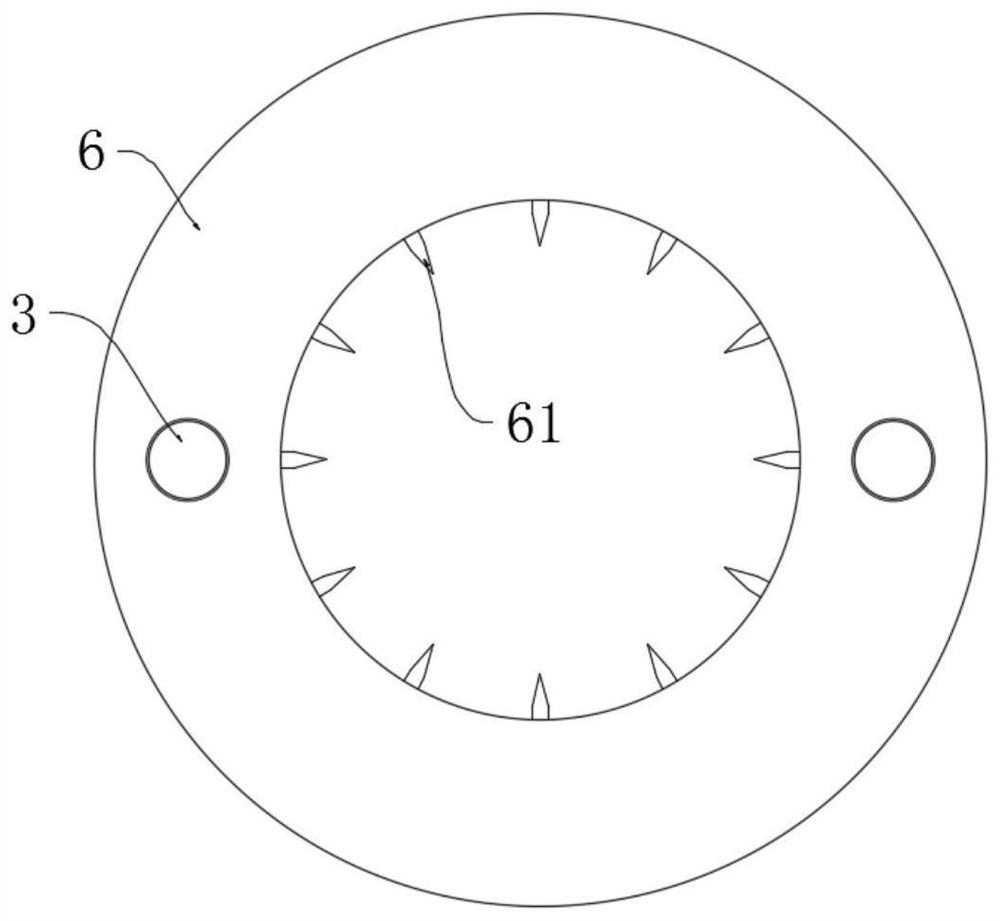

Silencing shot blasting machine

PendingCN107617980AStable speedIncrease exerciseAbrasive machine appurtenancesMotor driveInsulation layer

The invention discloses a silencing shot blasting machine. The silencing shot blasting machine comprises bases, first friction wheels, second friction wheels matched with the first friction wheels, amotor and a roller provided with steel shots. The roller is sleeved with the first friction wheels, the second friction wheels are installed on the bases and compacted with the first friction wheels,and the motor is connected with the second friction wheels through conveying belts. The silencing shot blasting machine further comprises an electromagnet, a normally open trigger switch and racks, the normally open trigger switch is electrically connected with the electromagnet, the electromagnet is fixed on one rack and located above the roller, the inner wall of the roller comprises a sound insulation layer and a silencing layer, and the sound insulation layer and the silencing layer are arranged on the inner wall of the roller in a stacked manner. The silencing shot blasting machine has the advantages that except that the motor drives the roller to rotate, by arranging the electromagnet, the stable rotating speed of the roller is guaranteed, movement of the steel shots is also strengthened, and thus the shot blasting efficiency is effectively improved.

Owner:JIANGSU GELIN MACHINERY

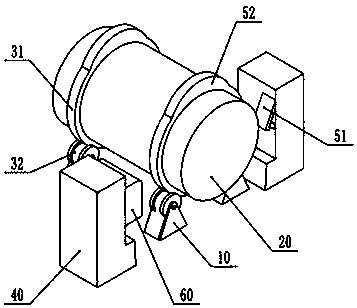

A longitudinal axis rotation mechanism and control system for laser guidance

ActiveCN109173088BAccurate angleAccurate adjustment effectX-ray/gamma-ray/particle-irradiation therapyMedical equipmentControl system

The invention belongs to the technical field of medical equipment, and discloses a longitudinal axis rotation mechanism for laser guidance, including a shaft sleeve, a rotating shaft arranged in the shaft sleeve and rotatably connected with the shaft sleeve and connected with the laser-guided puncturing device at one end in the longitudinal direction, and a power generating device connected with the end of the rotating shaft far away from the laser-guided puncturing device and connected with a control system, wherein the rotating shaft sleeve is connected with the laser-guided puncturing device at one end in the longitudinal direction. The invention also discloses a control system for a longitudinal axis rotation mechanism guided by a laser, comprising a power source A, a PLC connected with the power source A, a braking device and a power generating device. The invention controls the rotation of the longitudinal axis rotation mechanism by controlling the running and stopping of the power generating device by a computer, which is simple in operating and accurate in position. The braking device is connected with the power generating device, and the power generating device can be braked in time, so that the angle of laser emission is more accurate.

Owner:成都真实维度科技有限公司 +1

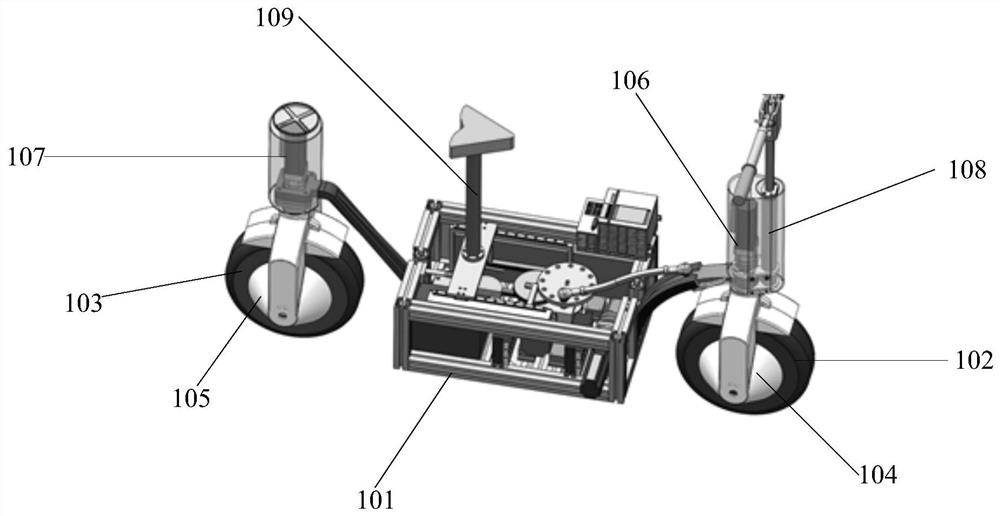

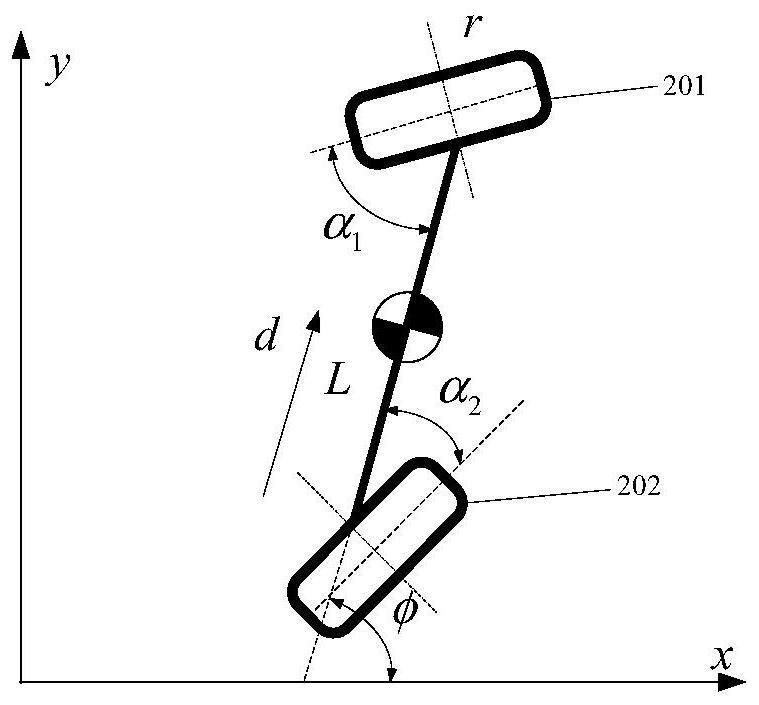

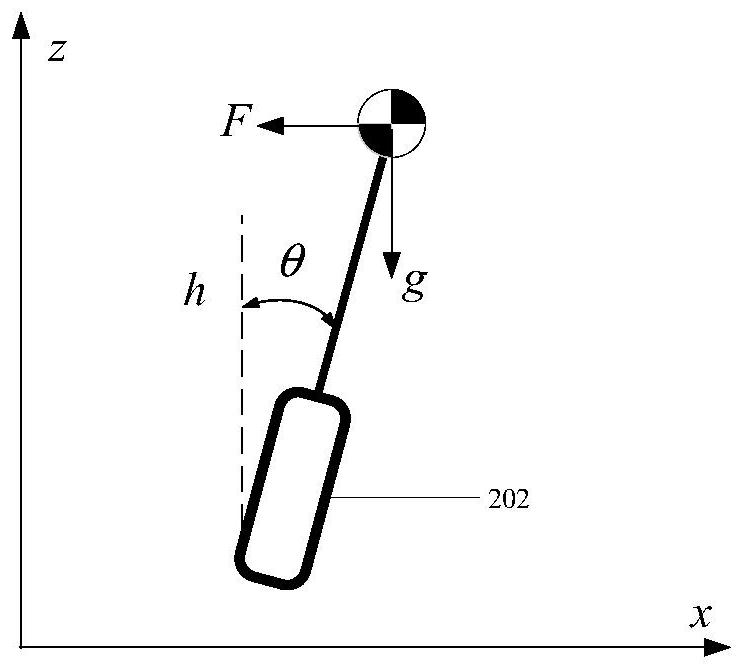

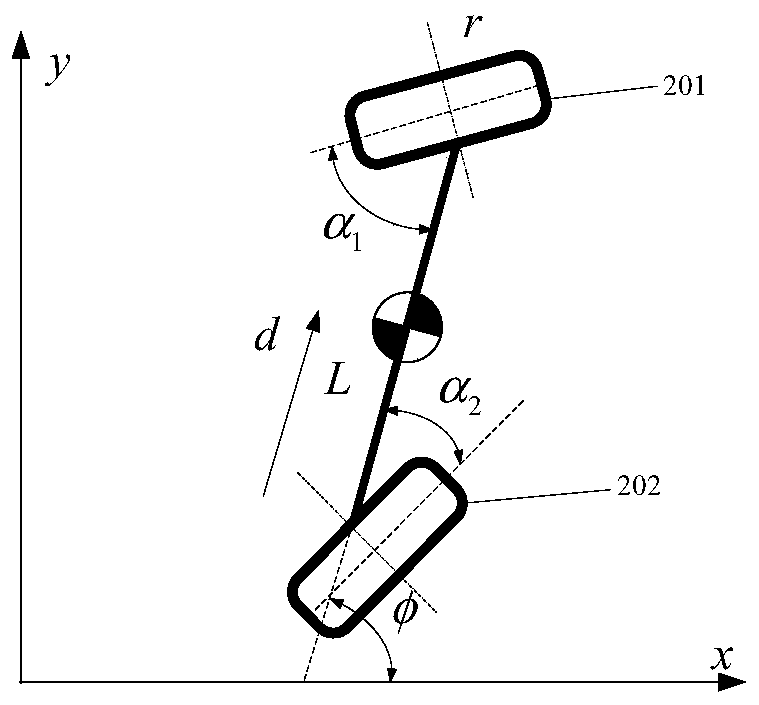

Wheeled mobile device, balance control method and storage medium

ActiveCN111284623BImplement automatic deformationImprove convenienceCycle equipmentsConvertible cyclesVertical planeControl engineering

The embodiment of the application discloses a wheeled mobile device, a balance control method and a storage medium, which belong to the field of computer technology. The wheeled mobile device includes a body, a first hub, a second hub and a controller. The body includes a first end, a second end, a third end and a fourth end; the first hub is arranged at the first end, and the second hub is arranged at the The second end; the controller is electrically connected to the first hub and the second hub respectively; the controller controls the rotation of the first hub and the second hub in response to satisfying the state switching condition, so that the wheeled mobile device switches from the current state to the target state ; During the switching process, the controller controls the first hub to move towards the target direction along the vertical plane where the first hub is located, and the target direction is a direction close to the lower end of the third end and the fourth end, the first The hub is a hub used to control the moving direction of the wheeled mobile device in the wheeled mobile device, and can be automatically deformed to improve the convenience of the wheeled mobile device.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Energy-saving type new energy vehicle windscreen wiper driving structure

The invention discloses an energy-saving new energy vehicle windscreen wiper driving structure which comprises a front automobile body, two rotating shafts are arranged at the upper end of the front automobile body, windscreen wipers are fixedly connected to the side walls of the two rotating shafts, and a mounting box is fixedly connected to the inner wall of the front automobile body; a driving mechanism used for driving the two windscreen wipers to rotate is arranged in the mounting box, the driving mechanism comprises a rotating rod rotationally connected to the inner wall of the mounting box, one end of the rotating rod is fixedly connected with a rotating box, and the inner wall of the rotating box is elastically connected with two moving plates through two pressure springs; a moving block is slidably connected to the inner wall of the rotating box, drainage ports are formed in the two side walls of the rotating box in a penetrating mode, and sealing plugs are elastically connected to the two side walls of the rotating box through a plurality of springs. The windscreen wiper can be automatically started in rainy days, manual control of a driver is not needed, electric energy in the automobile does not need to be used, energy is greatly saved, and the driving distance of the new energy vehicle is prolonged.

Owner:HUZHOU YUEBIN INTELLIGENT TECH CO LTD

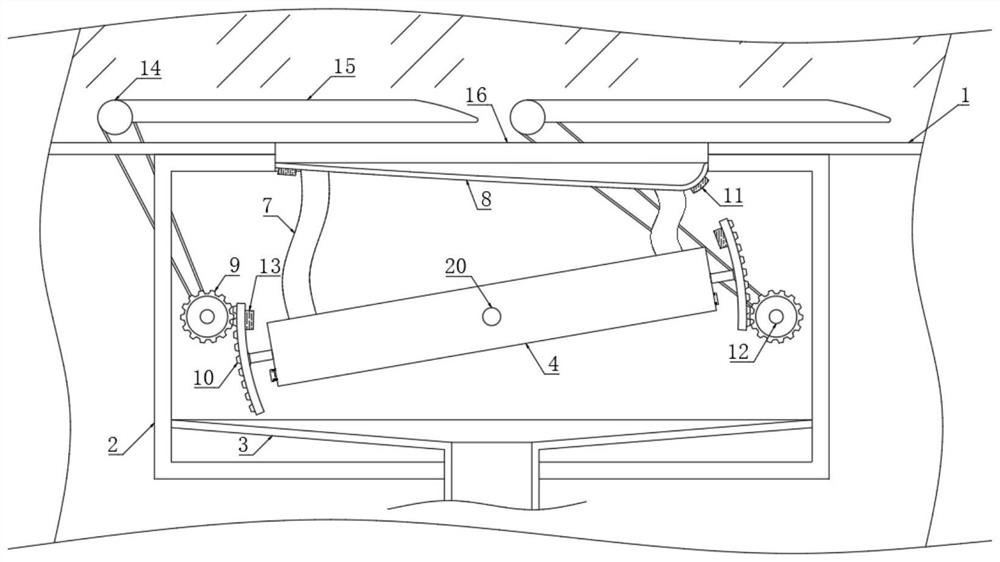

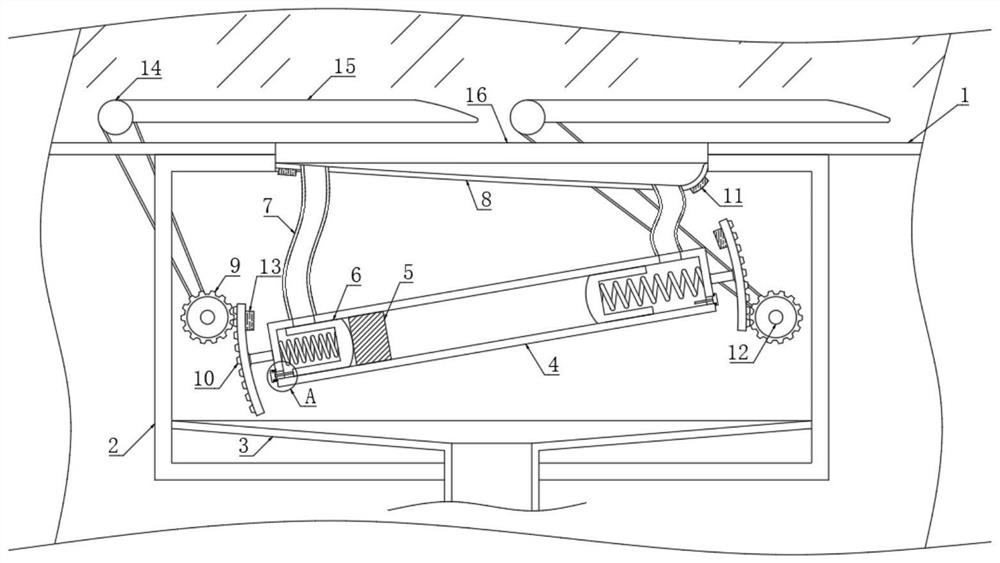

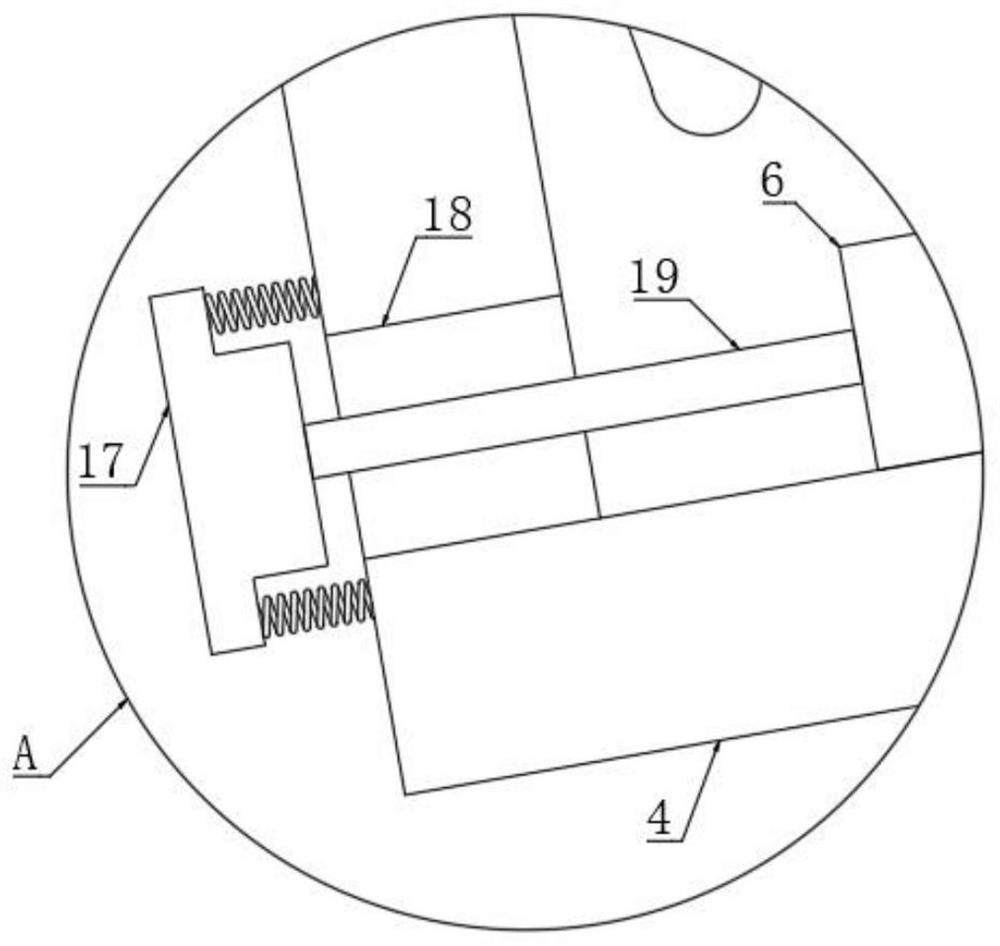

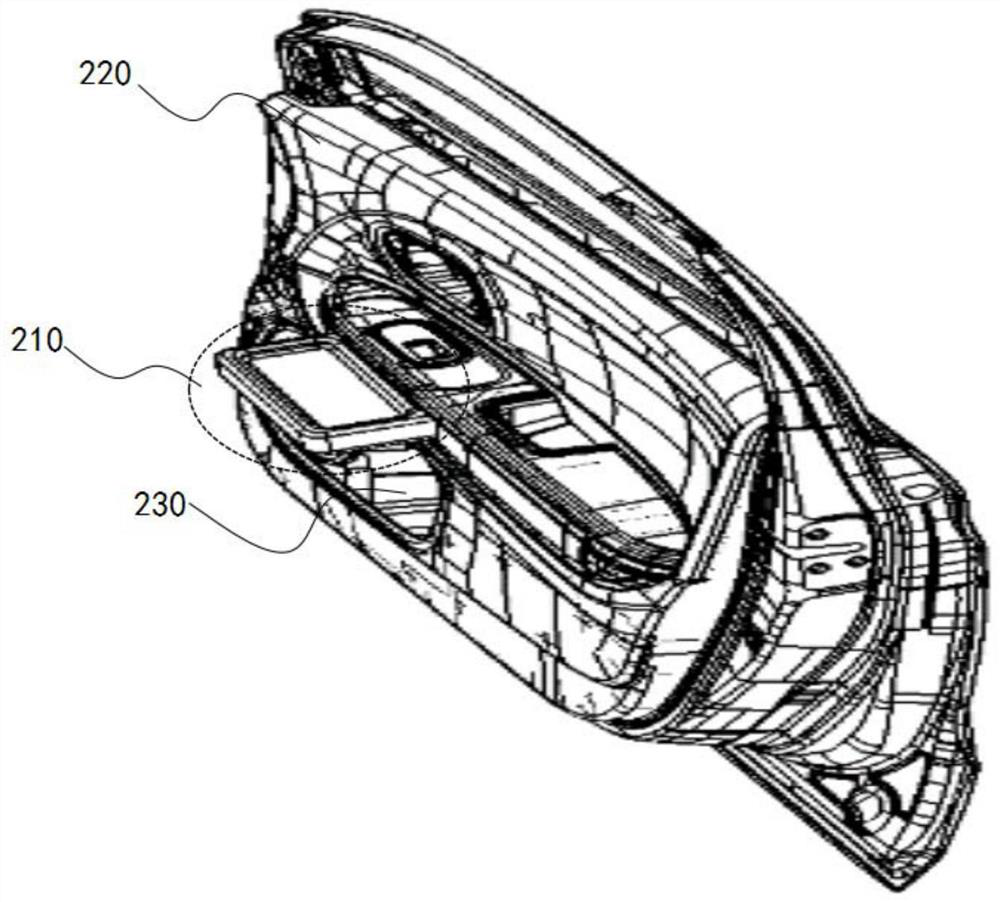

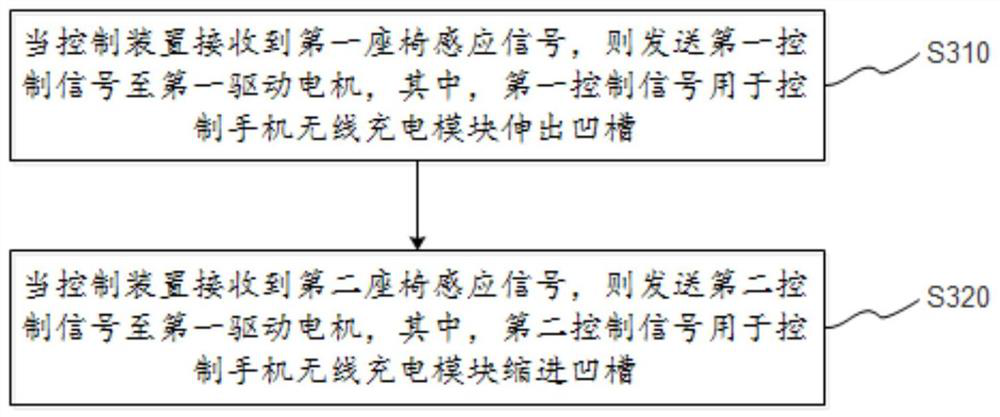

Vehicle door mobile phone wireless charging system, control method thereof and vehicle

PendingCN113370767ANo manual controlsVehicle seatsBatteries circuit arrangementsMobile phoneInductive charging

The invention discloses a vehicle door mobile phone wireless charging system, a control method thereof and a vehicle, and relates to the field of vehicle automation control. The vehicle door mobile phone wireless charging system comprises a mobile phone wireless charging device, a seat sensor and a control device; the mobile phone wireless charging device comprises a mobile phone wireless charging module and a first driving motor; the mobile phone wireless charging device is arranged on an interior trimming panel of a vehicle door, and the interior trimming panel is provided with a groove; and the mobile phone wireless charging module extends out of or retracts into the groove through the first driving motor. The seat sensor is used for detecting the seating condition of a seat, the control device is connected with the seat sensor and the first driving motor, and the control device controls the first driving motor according to the seating condition of the seat sensor, so that the mobile phone wireless charging module automatically stretches out when a passenger sits on the seat, and the mobile phone wireless charging module retracts when the passenger leaves the seat. The mobile phone wireless charging module is adopted to charge the mobile phone, the mobile phone wireless charging module can stretch out and draw back automatically, manual operation is not needed, and the mobile phone is convenient to charge.

Owner:GUANGQI HONDA +1

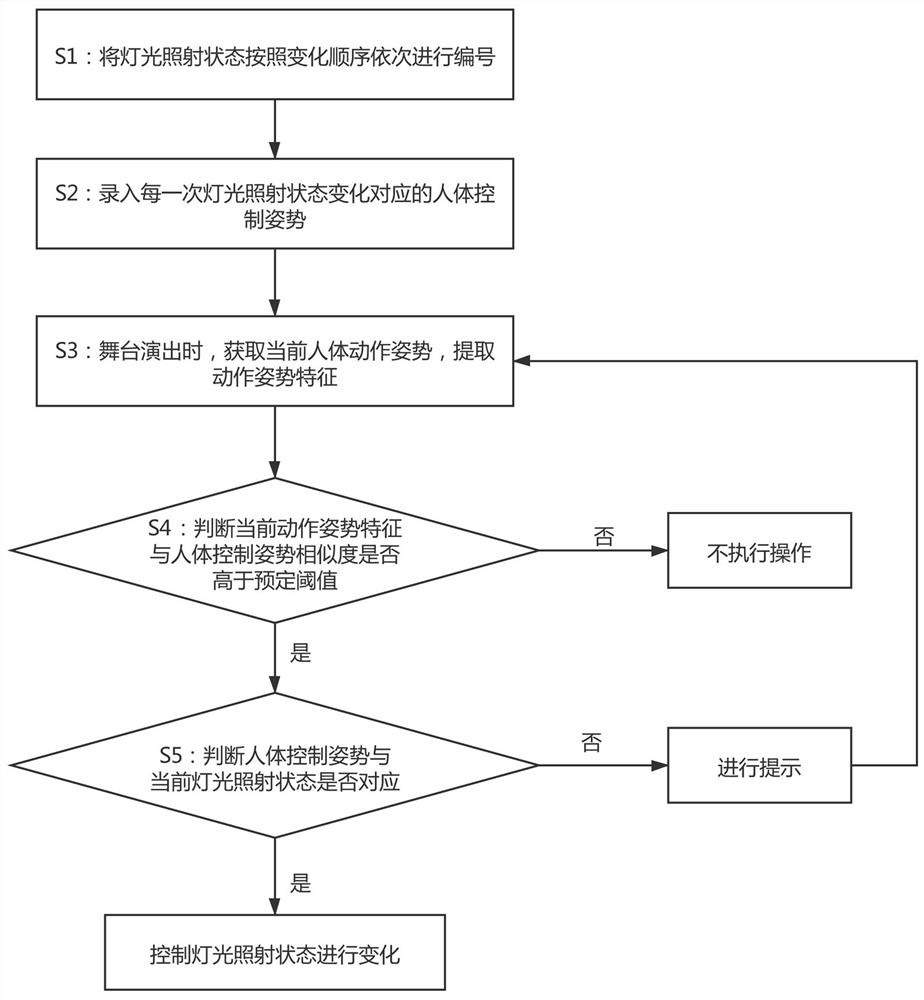

A lighting intelligent control method

ActiveCN110677964BHigh precisionReduce mistakesElectrical apparatusEnergy saving control techniquesIntelligent lightingHuman body

The present invention provides a lighting intelligent control method, which relates to the technical field of stage control. The method includes the following steps: S1: sequentially numbering the light irradiation states according to the order of change; S2: entering the human body control posture corresponding to each light irradiation state change; S3: During the stage performance, obtain the current human action posture and extract the action posture features; S4: Determine whether the similarity between the current action posture features and the human control posture is higher than the predetermined threshold, if so, execute S4, otherwise, do not operate; S5: Judgment Whether the human body control posture corresponds to the current lighting state, if so, control the lighting state to change, otherwise, prompt, and repeat S3. The light intelligent control method of the present invention is convenient to control, intelligent and reasonable, and the light change control is performed by the specific actions of the performers on the stage, the change program can be set in advance, the light change has higher accuracy, smaller error, and does not require staff Manual control.

Owner:杭州友邦文化科技有限公司

A kind of vermicelli collecting device

ActiveCN109515784BNo manual controlsQuick action in and out of the income boxSolid materialSlide plateControl theory

Owner:宣城市宣华食品有限公司

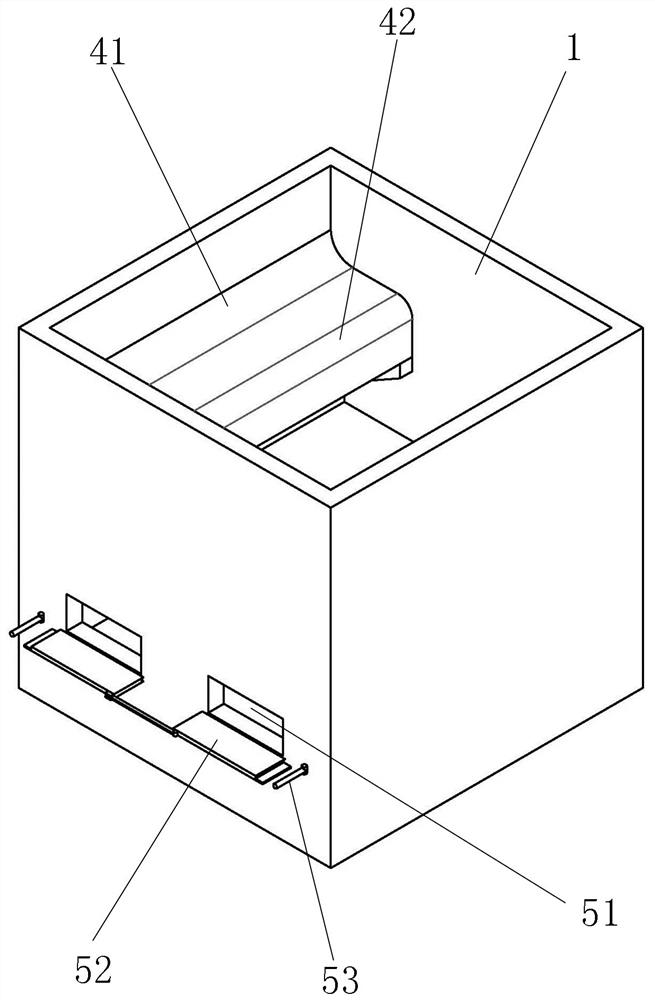

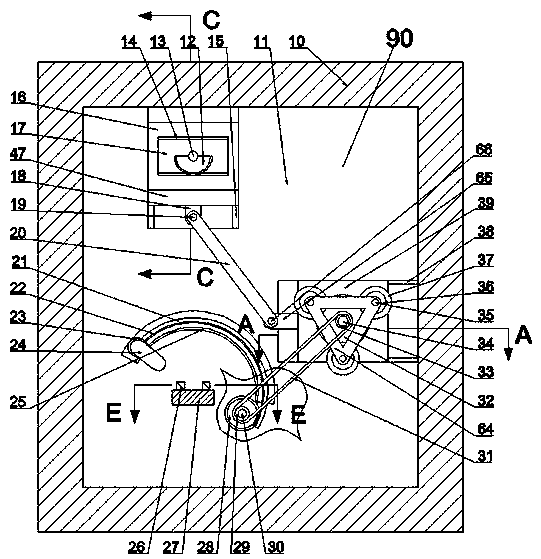

A device for automatic scanning and processing of book images

ActiveCN110933247BSimple structureSimple and fast operationPictoral communicationMechanical engineeringFully automated

The invention discloses an automatic scanning and processing equipment for book images, which comprises a body, the body includes a working cavity, a working mechanism is arranged in the working cavity, a fan-shaped chute is arranged on the front end wall of the working cavity, and the fan-shaped A matching slider is slid in the chute, a fan-shaped block is fixed at the right end of the matching slider, a fan-shaped friction surface is provided at the bottom end of the fan-shaped block, and a first rotating shaft is rotated on the lower side of the right end of the fan-shaped chute. A friction wheel is fixed on the first rotating shaft; the structure of the invention is simple and the operation is simple, and the invention can automatically scan and process the documents or images that need to be scanned. Cooperate to complete the complete project of page turning and left and right scanning, without manual control, with a high degree of integration.

Owner:浙江东盛科技有限公司

A short circuit protection device

ActiveCN111477478BAvoid affecting production capacityProtect electrical equipmentContact operating partsSwitch power arrangementsStructural engineeringShort circuit protection

The invention discloses a short-circuit protection device, which comprises a casing, and a neutral line cavity, a protection cavity and a grounding cavity are respectively opened in the casing from top to bottom, a neutral line is installed in the neutral line cavity, and a neutral line is installed in the grounding cavity A grounding piece is installed inside, and a protective wire and two symmetrical grounding wires are respectively installed on the grounding piece. Three pairs of terminal posts are symmetrically installed on the side wall of the housing, and two sliding rods are symmetrically installed in the protection chamber. , two spring wires are symmetrically wound on the two sliding rods. The invention shrinks and disconnects the magnetic plug and the magnetic sleeve by using the increase of the short-circuit current to cause the magnetic field of the spring wire itself to increase, and the magnetic field weakens after the short-circuit current is eliminated, so that the spring wire rebounds and pushes the magnetic plug and the magnetic sleeve to connect to the connecting line, thereby realizing the short circuit Self-recovery function, increase the safety of short-circuit protection through the protection ring.

Owner:深圳市中创电测技术有限公司

Wheel type mobile equipment, balance control method and storage medium

ActiveCN111284623AImplement automatic deformationImprove convenienceCycle equipmentsConvertible cyclesVertical planeControl engineering

The embodiment of the invention discloses wheel type mobile equipment, a balance control method and a storage medium, and belongs to the technical field of computers. The wheel type mobile equipment comprises a body, a first hub, a second hub and a controller, wherein the body comprises a first end, a second end, a third end and a fourth end; the first hub is arranged at the first end, and the second hub is arranged at the second end; the controller is electrically connected with the first hub and the second hub. The controller controls the first hub and the second hub to rotate in response tothe condition that the state switching condition is met, so that the wheel type mobile equipment is switched from the current state to the target state; handover process, the controller controls thefirst hub to move in the target direction along the vertical plane where the first hub is located. The target direction is the direction close to the lower end of the third end and the fourth end, thefirst hub is used for controlling the moving direction of the wheel type mobile equipment in the wheel type mobile equipment, automatic deformation can be achieved, and the convenience of the wheel type mobile equipment is improved.

Owner:TENCENT TECH (SHENZHEN) CO LTD

Tractor implement management control method

ActiveCN106717212BNo manual controlsEasy to operateAgricultural machinesAdjusting devicesControl powerElectronic control system

The invention discloses a tractor tool management and control method, and belongs to the technical field of tractors. The method is used for controlling an electronic control power output device and an electronic control hydraulic reverse valve on the basis of an electronic control system and height data of an electronic control lifter. The method comprises the following steps that an operation mode selection switch is operated, a power output operation mode is activated, when the electronic control lifter exceeds the preset power output safe height, the electronic control power output device is powered off, and when the electronic control lifter is in a safe height range, the electronic control power output device is combined; the operation mode selection switch is operated, a turning tool operation mode is activated, and when the electronic control lifter rises to the safe turning height from the operation height range, the electronic control hydraulic reverse valve conducts reversing, and then a turning tool conducts turning. According to the tractor tool management and control method, the power output device and the turning tool are automatically powered off or combined on the basis of the height of the lifter, manual control is not needed, operation of a manipulator is simplified, the operation efficiency is improved, and damage caused by misoperation of the manipulator to the tool or a tractor power output shaft is avoided.

Owner:LOVOL HEAVY IND CO LTD

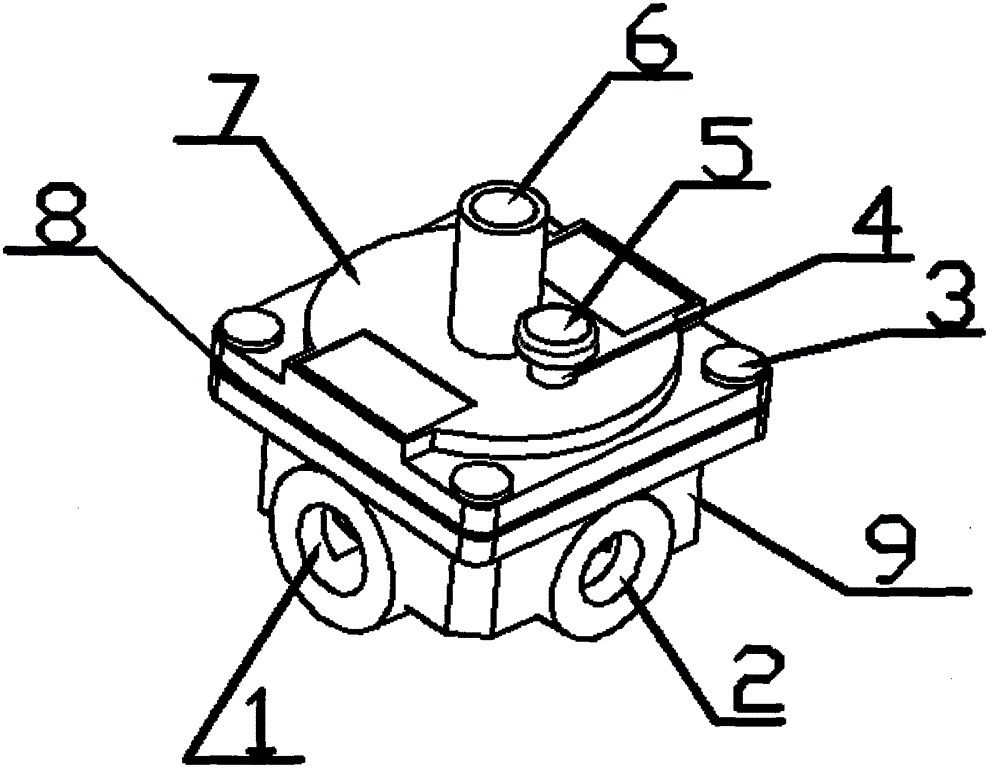

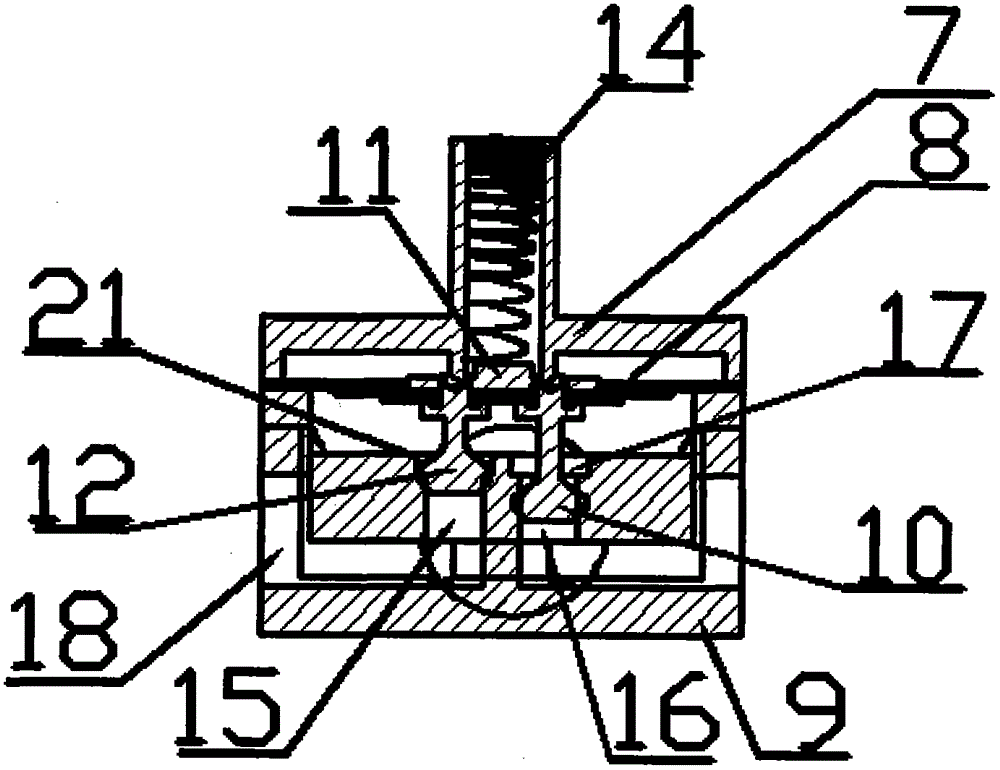

A double gas source automatic selection valve

InactiveCN104089049BImprove stabilitySimple structureOperating means/releasing devices for valvesMultiple way valvesProduct gasEngineering

Owner:唐宗华

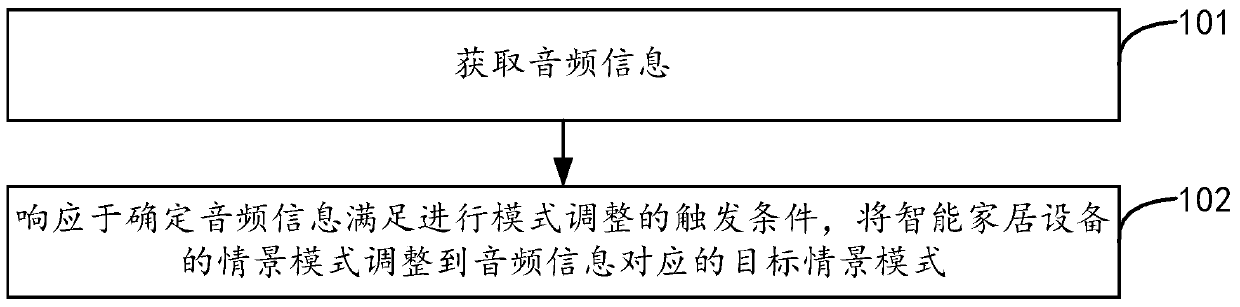

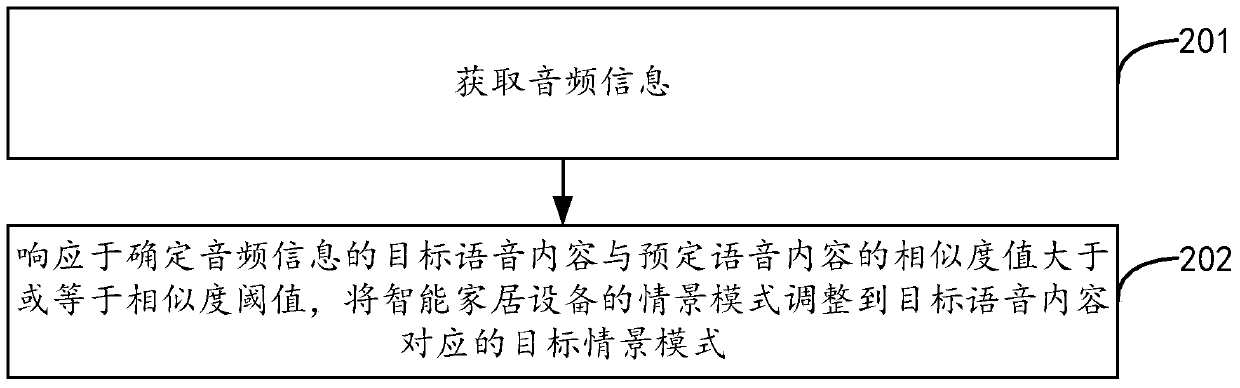

Scenario mode adjustment method and device for smart home equipment

ActiveCN105204357BImprove regulation efficiencyRealize automatic adjustmentComputer controlProgramme total factory controlComputer scienceModel regulation

Owner:XIAOMI INC

Fully automatic high concentration sodium hypochlorite generating system

Owner:FUJIAN HADA INTELLIGENCE TECH CO LTD +1

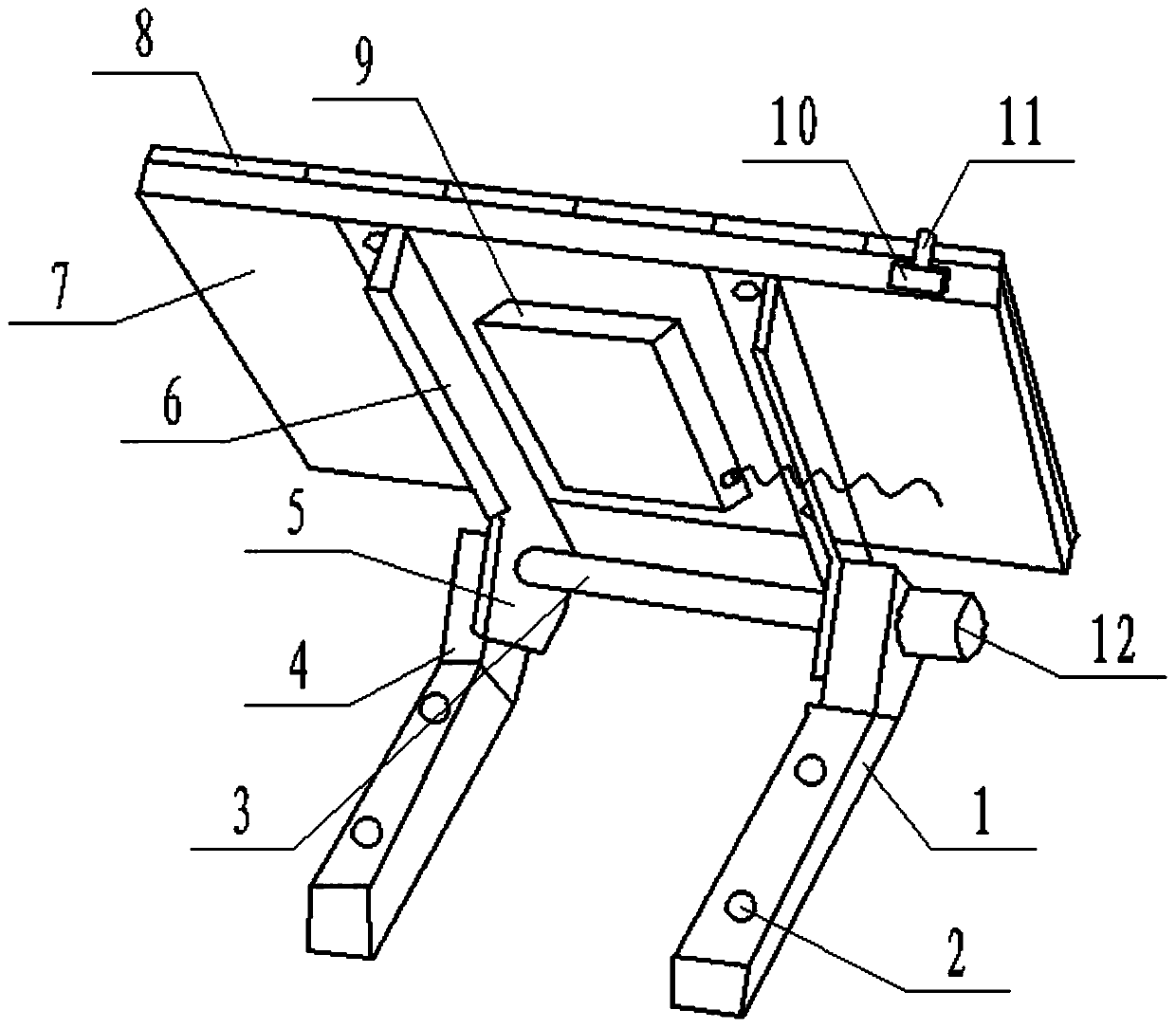

Rotatable solar panel support

InactiveCN111555704AEasy to operateSolve the problem of low degree of adjustment automationPhotovoltaic supportsSolar heating energyRotational axisIlluminance

The invention discloses a rotatable solar panel support, which comprises a mounting underframe, fixing holes, a rotating shaft and a supporting base, wherein the fixing holes are formed in the mounting underframe; the supporting base is arranged at one end of the mounting underframe; a rotating base is arranged on the side edge of the supporting base; the rotating shaft is arranged in the rotatingbase; a micro motor is arranged at one end of the rotating shaft; an upper supporting frame is arranged at the upper end of the rotating base; and a mounting plate is arranged on the upper supportingframe. The beneficial effects are that: the inclination angle of the solar panel support can be adjusted at any time; an illuminance sensor monitors the sunlight receiving condition of the solar panel to judge whether the solar panel is in a direct sunlight state or not; a control box controls the micro motor to adjust the rotating angle of the upper supporting frame according to the sunlight irradiation condition, and thus the light energy utilization rate is effectively increased.

Owner:廖高勇

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com