A longitudinal axis rotation mechanism and control system for laser guidance

A laser-guided and rotating mechanism technology, which is applied in treatment, radiotherapy, X-ray/γ-ray/particle irradiation therapy, etc., can solve the problems of inaccurate particle implantation and inaccurate laser emission angle, and achieve accurate angle, Angle and position adjustments for precise results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

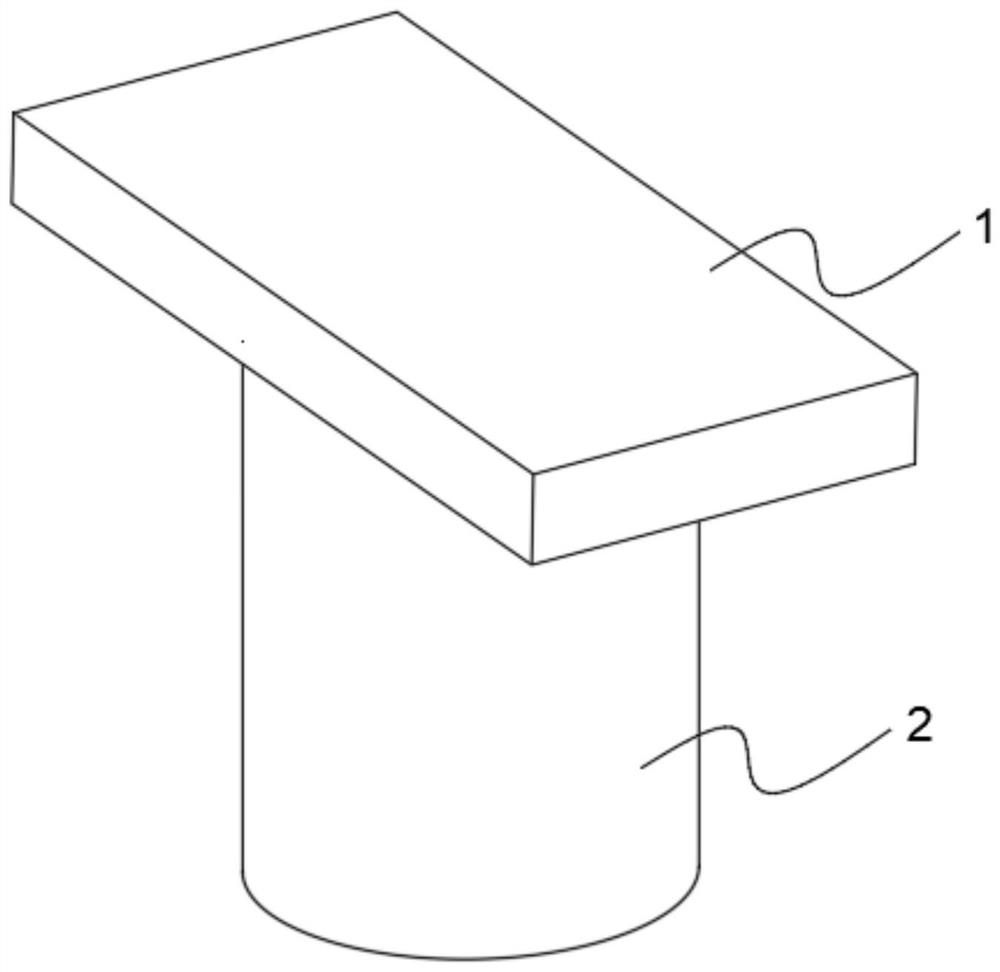

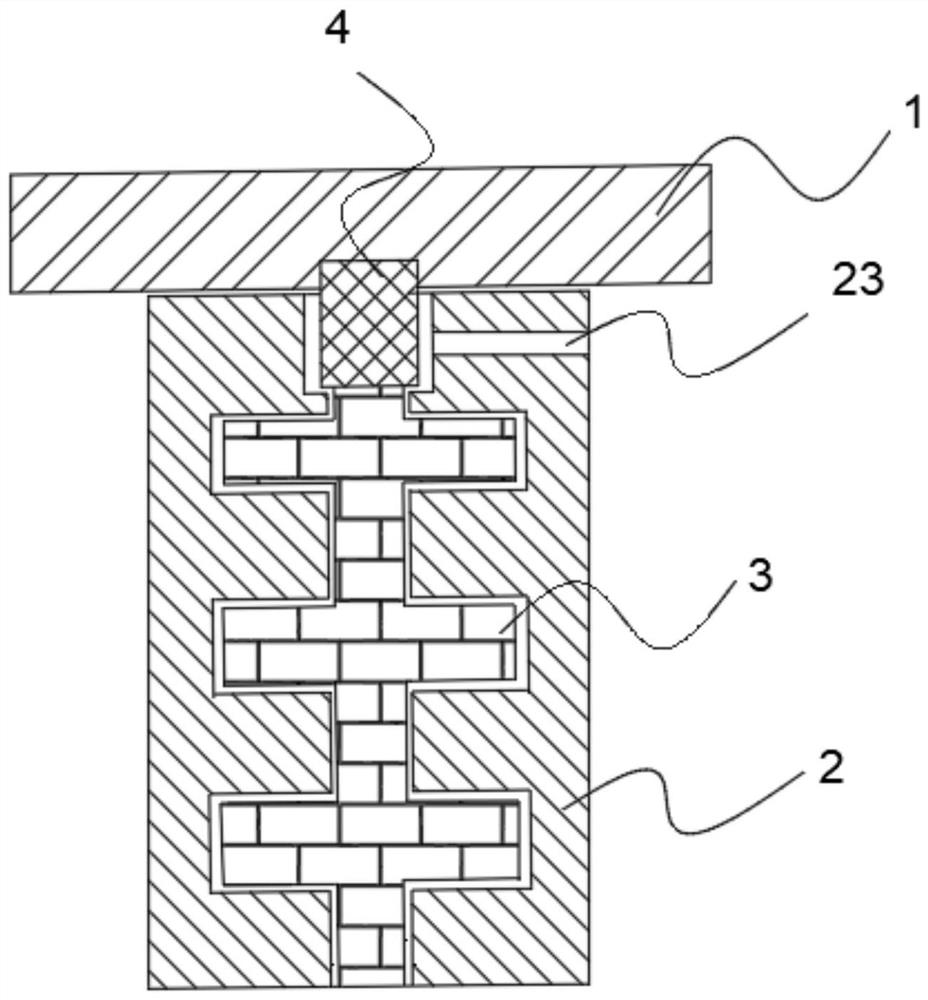

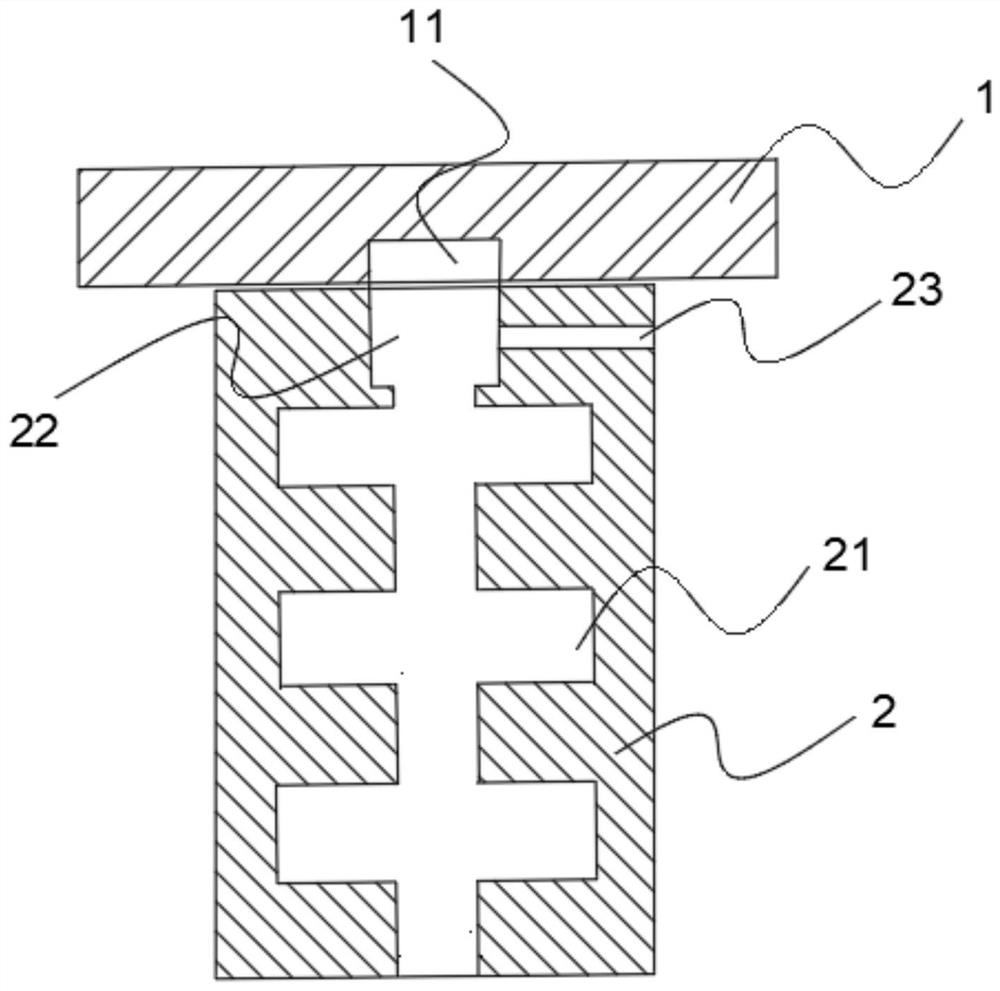

[0040] Such as Figure 1 to Figure 8 As shown, a longitudinal axis rotation mechanism for laser guidance in this embodiment includes a shaft sleeve 2, which is arranged in the shaft sleeve 2 and connected to the shaft sleeve 2 in rotation, and one end in the length direction is connected to the laser guide The rotating shaft 3 connected to the puncturing device and the power generating device 4 connected to the end of the rotating shaft 3 away from the laser-guided puncturing device and connected to the control system.

[0041] A control system for a laser-guided vertical axis rotation mechanism, including a power supply A, a braking device 41, a power generating device 4 and a PLC connected to the power supply A, the braking device 41 and the power generating device Devices 4 are all connected to the PLC.

Embodiment 2

[0043] This embodiment is a definition optimized on the basis of the above-mentioned embodiment 1, such as Figure 1 to Figure 8 As shown, a longitudinal axis rotation mechanism for laser guidance in this embodiment includes a shaft sleeve 2, which is arranged in the shaft sleeve 2 and connected to the shaft sleeve 2 in rotation, and one end in the length direction is connected to the laser guide The rotating shaft 3 connected to the puncturing device and the power generating device 4 connected to the end of the rotating shaft 3 away from the laser-guided puncturing device and connected to the control system.

[0044] Further, the longitudinal axis rotation mechanism also includes a mounting plate 1 whose end away from the ground is connected to the sliding mechanism of the laser-guided puncturing device, and the end of the shaft sleeve 2 in the length direction close to the power generating device 4 is connected to the The mounting boards 1 are connected. The mounting plate ...

Embodiment 3

[0048] This embodiment is a definition optimized on the basis of the above-mentioned embodiment 2, such as Figure 1 to Figure 9 As shown, a longitudinal axis rotation mechanism for laser guidance in this embodiment includes a shaft sleeve 2, which is arranged in the shaft sleeve 2 and connected to the shaft sleeve 2 in rotation, and one end in the length direction is connected to the laser guide The rotating shaft 3 connected to the puncturing device and the power generating device 4 connected to the end of the rotating shaft 3 away from the laser-guided puncturing device and connected to the control system.

[0049] The longitudinal axis rotation mechanism also includes a mounting plate 1 that is connected to the sliding mechanism of the laser-guided puncture device at an end far away from the ground, and the end of the shaft sleeve 2 that is close to the power generating device 4 in the length direction is connected to the mounting plate 1. Board 1 is connected. The mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com