Shot blasting machine

A technology of shot blasting machine and frame, which is applied in surface polishing machine tools, grinding/polishing equipment, machine tools suitable for grinding the edge of workpieces, etc. Insufficient effect and other problems, to achieve the effect of stable speed, enhanced movement, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in further detail below by means of specific embodiments:

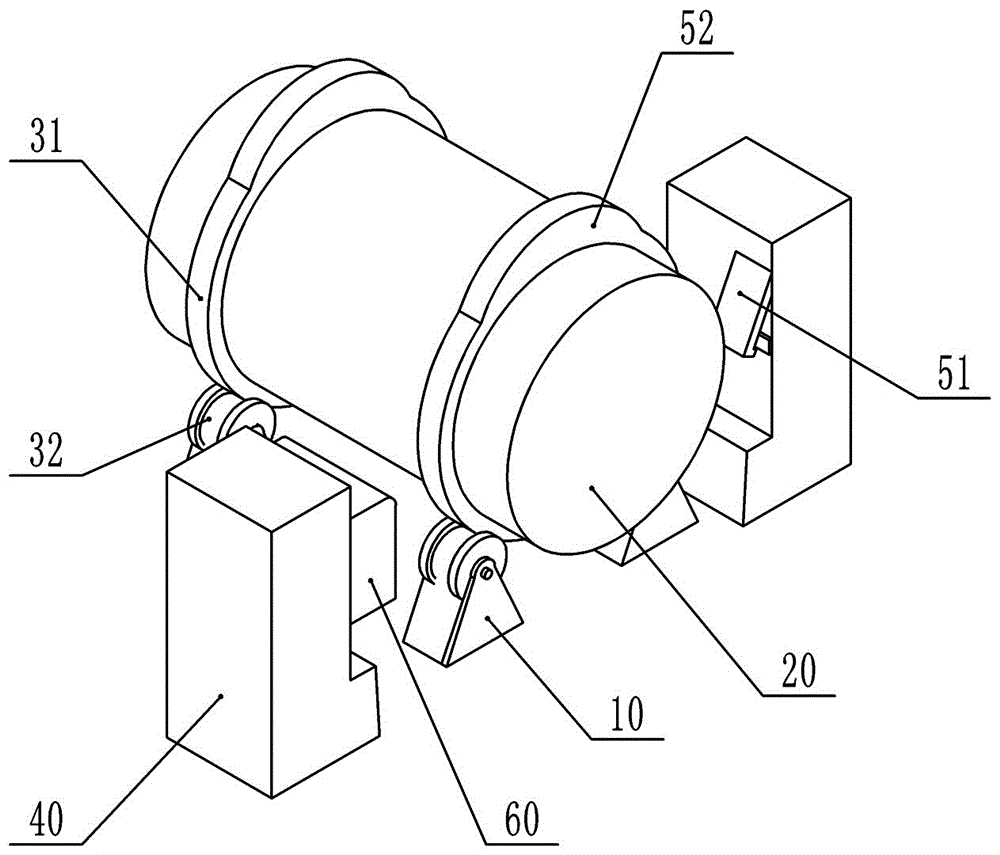

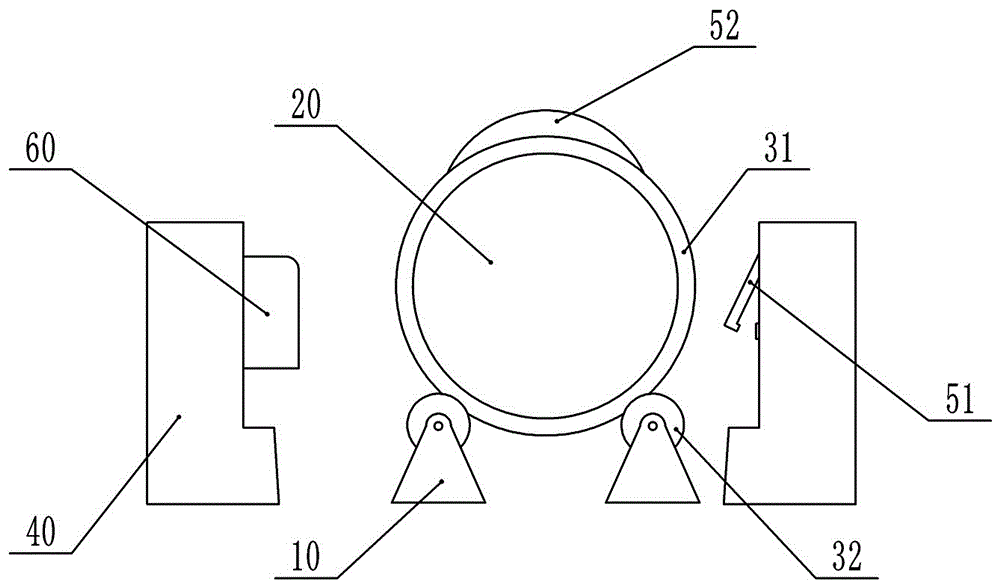

[0017] The reference numerals in the drawings of the specification include: base 10 , roller 20 , first friction wheel 31 , second friction wheel 32 , frame 40 , normally open trigger switch 51 , trigger block 52 , and electromagnet 60 .

[0018] Such as figure 1 , figure 2 As shown, the shot blasting machine includes a base 10, a first friction wheel 31, a second friction wheel 32 matched with the first friction wheel 31, a motor, a trigger block 52, a drum 20, an electromagnet 60, and an electromagnet 60. Connected normally open trigger switch 51 and frame 40. Steel shots are filled in the cylinder 20, and the cylinder 20 is made of aluminum alloy. On the one hand, the strength of the aluminum alloy is high and light in weight, and it is easy to move; The isolation effect prevents the aluminum alloy drum 20 from being magnetized, thereby attracting the steel shot to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com