Tractor tool management and control method

A management control, tractor technology, applied in the field of tractors, can solve the problems of reducing operating efficiency, tractor or implement damage, complicated operation, etc., and achieve the effects of improving operating efficiency, avoiding damage, and simplifying operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

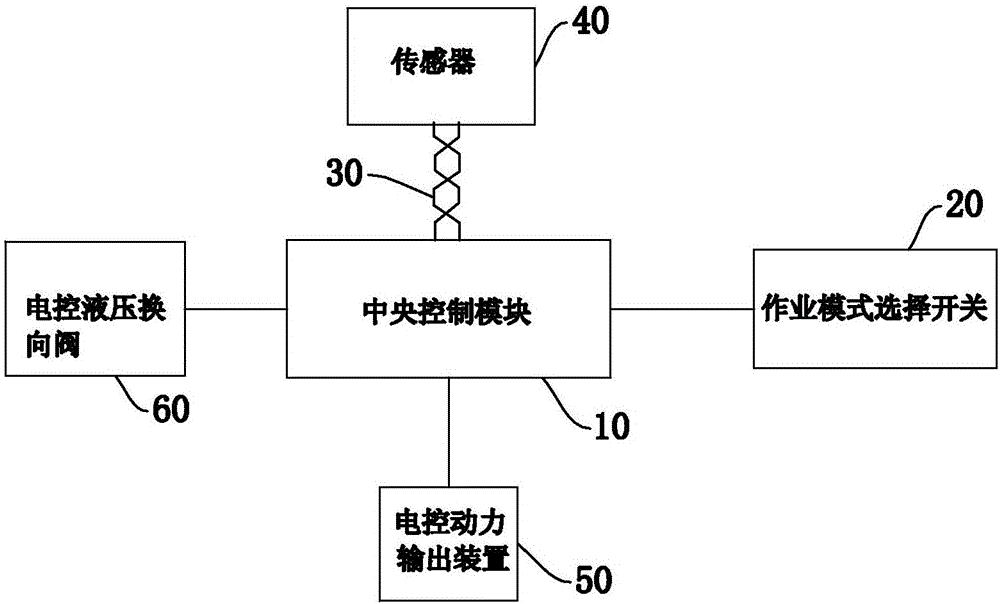

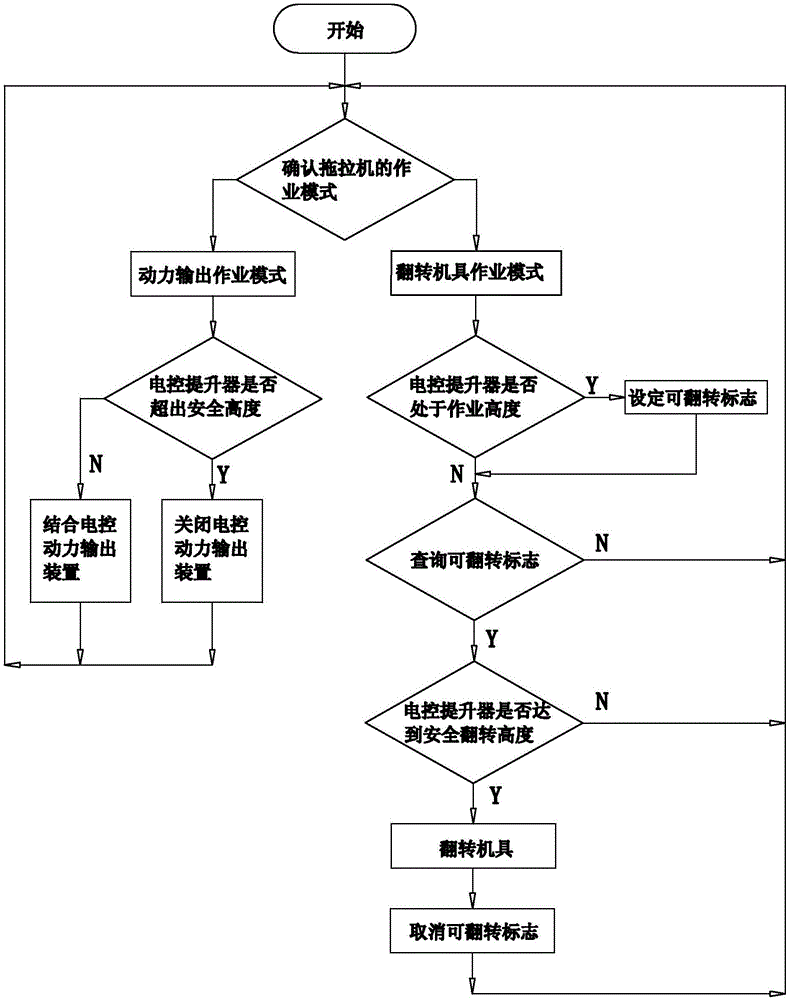

[0026] Such as figure 1 and figure 2 Commonly shown is a tractor implement management control method, based on the electronic control system and the height data of the electronic control lifter detected by the sensor, the tractor's electronically controlled power output device and the electronically controlled hydraulic reversing valve of the turning implement are controlled.

[0027] The electronic control system includes a connected central control module 10 and an operation mode selection switch 20; the central control module 10 is an independent controller or integrated in the electronic control unit of the tractor vehicle; the operation mode selection switch 20 is used as an electronic control The input of the system is not limited in form and quantity, it can be keys, buttons or human-computer interactive touch screen and so on.

[0028] In this embodiment, the electronic control lifter itself is equipped with a sensor 40 that can measure the height, and the central co...

Embodiment 2

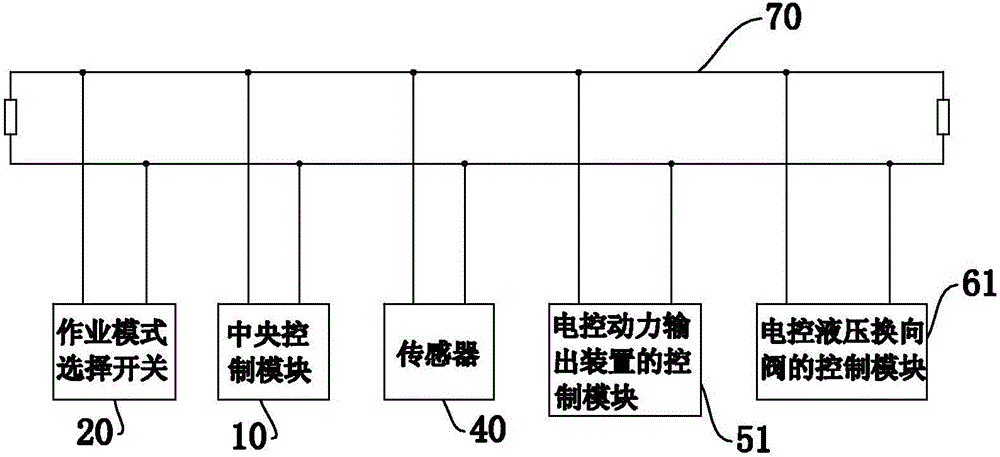

[0037] This embodiment is basically the same as Embodiment 1, the difference is that, as image 3 As shown, the central control module 10, the operation mode selection switch 20, the sensor 40, the control module 51 of the electronically controlled power output device and the control module 61 of the electronically controlled hydraulic reversing valve are in the same bus network.

[0038] The central control module 10 indirectly controls the control module 51 of the electronically controlled power output device and the control module 61 of the electronically controlled hydraulic reversing valve through the bus 70 .

[0039] The bus 30 and the bus 70 can be CAN bus or other forms of bus.

[0040] The tractor implement management control method provided by the present invention automatically closes or combines the power output device and flip implement based on the height of the lifter, without manual control, simplifies the operation of the operator, improves the working effici...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com