Single-screw refrigeration compressor heat pump system coupling air supply and composite slide valve

A refrigeration compressor and heat pump system technology, which is applied in the field of fluid machinery, can solve the problems of increasing the power consumption of the compressor and the large difference between the internal and external pressure ratio of the compressor, etc., and achieve the effect of improving intelligence and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

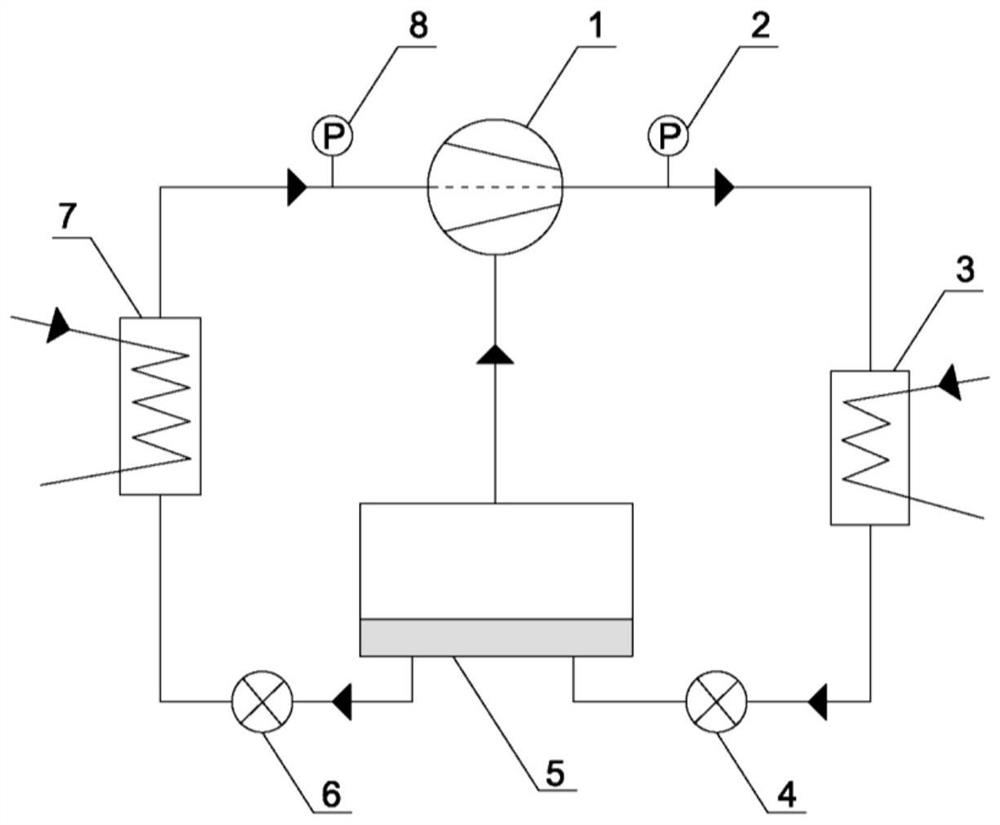

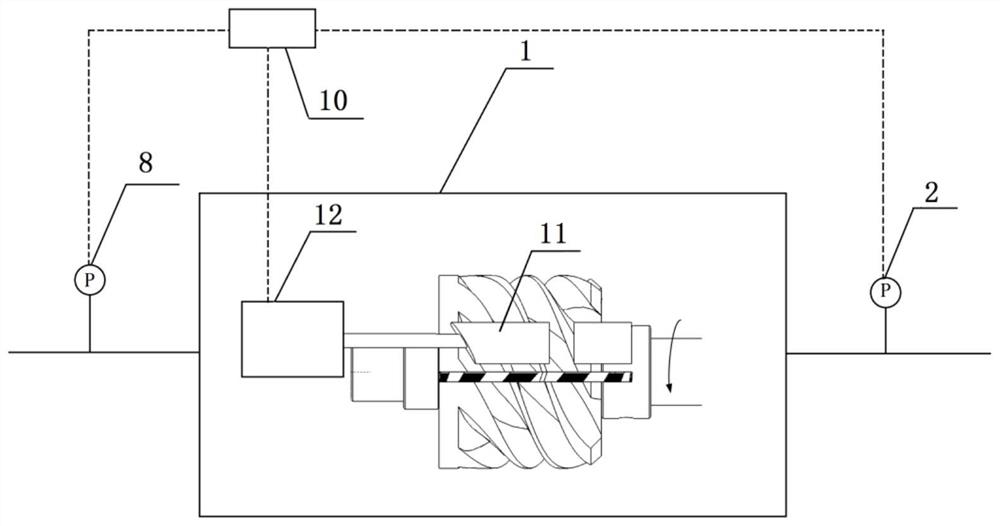

[0016] Embodiment 1: For the heat pump system that couples flasher air supply and composite slide valve, compressor (1) outlet is provided with first pressure sensor 2, and gas enters condenser (3) after coming out from compressor (1), and gas After the condenser (3) cools down, it enters the first-stage throttling element (4), throttling the medium-pressure gas-liquid mixture into the flasher (5), and the gas coming out of the flasher (5) is directly connected to the compressor ( 1) The gas supply port is connected, and the liquid from the flasher (5) enters the compressor (1) through the secondary throttling element (6) and the evaporator (7) in sequence. The inlet of the compressor (1) is provided with a second pressure sensor (8).

[0017] When the pressure in the heat pump system changes due to changes in the external environment, the first pressure sensor (2) and the second pressure sensor (8) detect that the system is working under the medium pressure ratio condition, a...

Embodiment 2

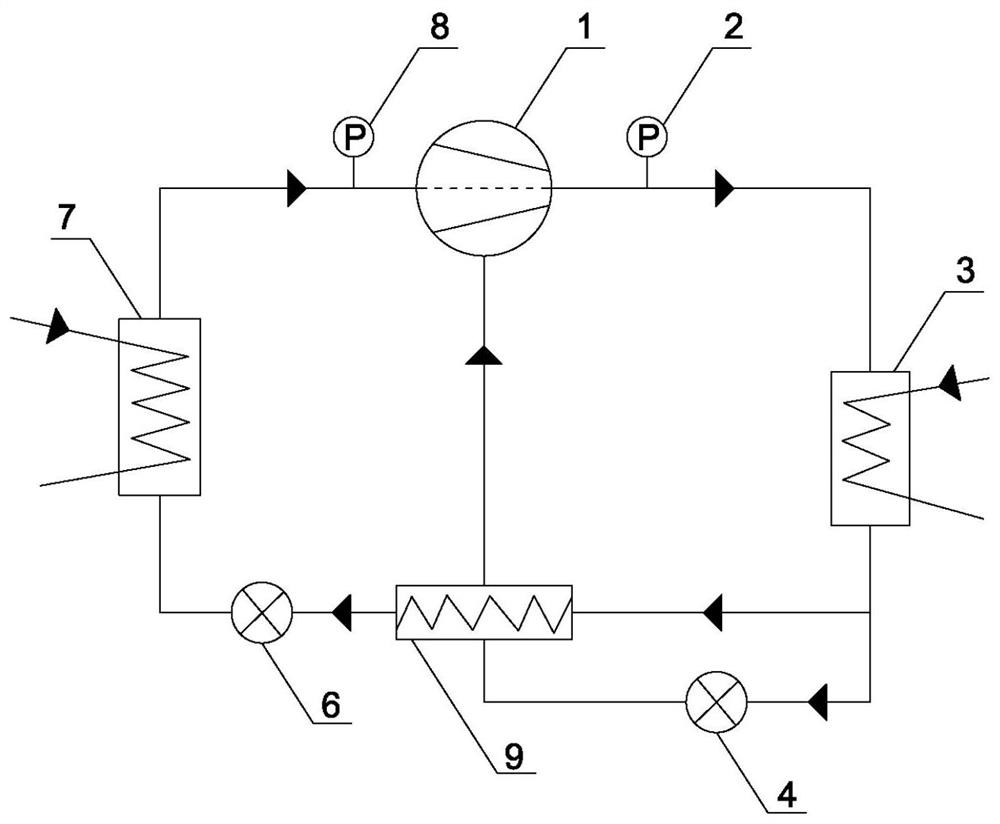

[0018] Embodiment 2: For the heat pump system coupled with subcooler air supply and composite slide valve, the compressor (1) outlet is provided with a first pressure sensor 2, and the gas enters the condenser (3) after coming out of the compressor (1), and the gas After the condenser (3) is cooled, it enters the first-stage throttling element (4), throttling the gas-liquid mixture at medium pressure and then enters the subcooler (9), and the gas after absorbing heat enters the compressor directly through the air supply port of the compressor (1). The gas from the condenser (3) directly enters the subcooler (9) to heat the throttling gas-liquid mixture, and the liquid directly from the subcooler (9) passes through the secondary throttling element (6), the evaporator ( 7) Enter the compressor (1). The inlet of the compressor (1) is provided with a second pressure sensor (8).

[0019] When the pressure in the heat pump system changes due to changes in the external environment,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com