Silencing shot blasting machine

A shot blasting machine and frame technology, applied in the field of mechanical equipment, can solve the problems of reducing work efficiency and cleaning quality, and achieve the effects of improving efficiency, avoiding noise pollution, and eliminating noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The following examples can enable those skilled in the art to understand the present invention more comprehensively, but the present invention is not limited to the scope of the described examples.

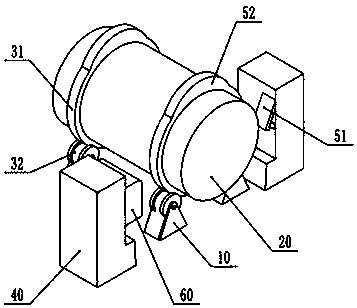

[0015] Such as figure 1 As shown, a noise-absorbing shot blasting machine includes a base 10, a first friction wheel 31, a second friction wheel 32 matched with the first friction wheel 31, a motor, and a drum 20 provided with steel shots. The inner wall of the drum 20 includes a sound-proof layer and the sound-absorbing layer, the sound-insulating layer and the sound-absorbing layer are stacked on the inner wall of the drum 20, and the sound-insulating layer and the sound-absorbing layer are also stacked with a resin buffer material layer. The first friction wheel 31 is sleeved on the surface of the cylinder 20, the second friction wheel 32 is installed on the base 10, and pressed against the first friction wheel 31, the motor is connected with the second friction wheel 32...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com