Silica brick

A technology of silicon mulberry brick and brick body, applied in the field of silicon mulberry brick, can solve the problems of large gap, no bonding effect of binder, uneven application of binder, etc. Firm, uniform filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

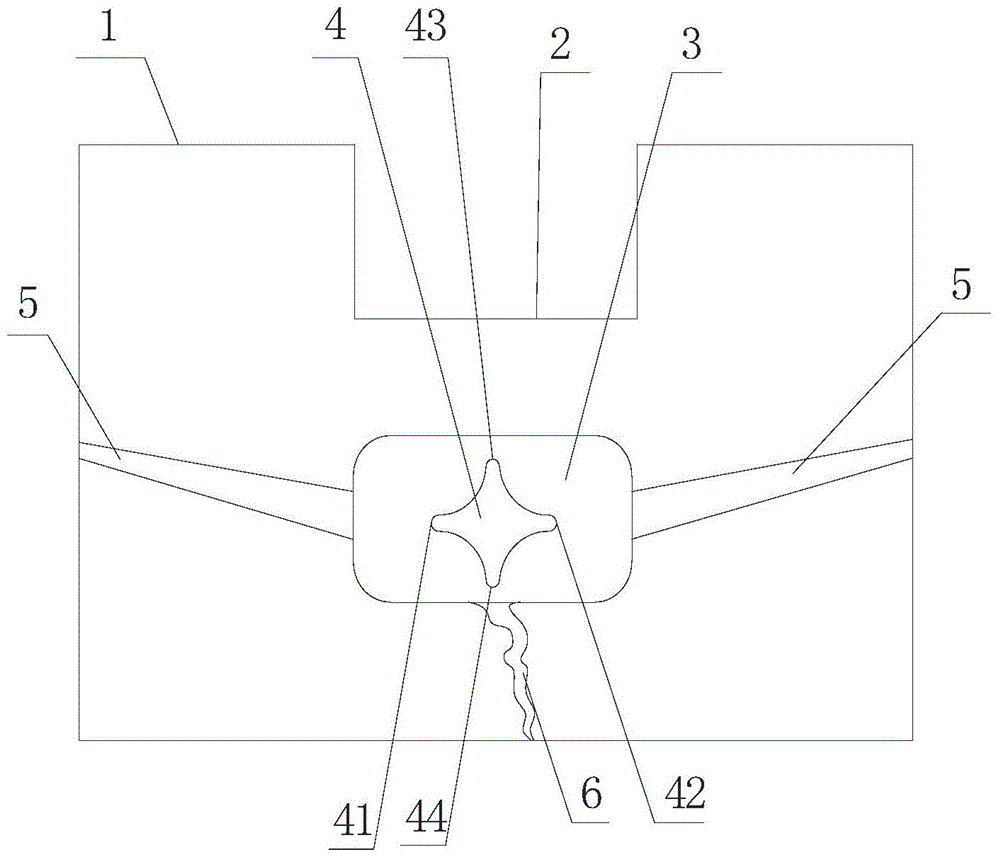

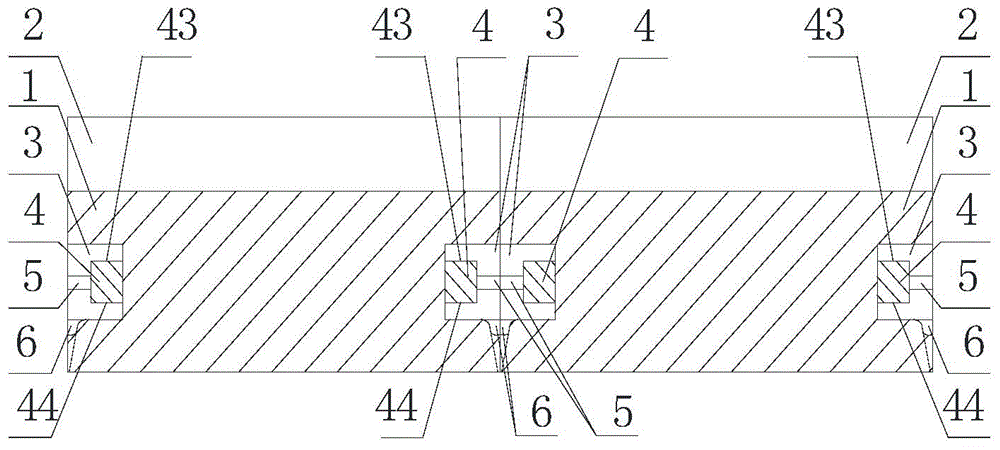

[0012] Such as figure 1 and 2 As shown, the silica brick includes a brick body 1, and the top of the brick body 1 is provided with a through groove 2 that runs through the front and rear sides of the brick body. Groove 3, the groove 3 is provided with a drainage plate 4, and the left side of the groove 3 on the front and rear sides of the brick body 1 is provided with a drainage groove 5 connecting the groove 3 and the left side of the brick body 1 The right side of the groove 3 on the front and rear sides of the brick body 1 is also provided with a drainage groove 5 communicating with the groove 3 and the right side of the brick body 1, and the groove width of the drainage groove 5 is between it and One end connected to the groove 3 gradually decreases in the direction extending to the other end, and the front and rear sides of the brick body 1 are provided with a zigzag sheep intestine groove 6 connected to the groove 3 below the groove 3, and the sheep intestine The width...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com