Method of Improving the Consistency of Flow Measurement Error of Time-Difference Ultrasonic Heat Meter

A flow measurement and ultrasonic technology, which is applied in the field of improving the flow measurement error consistency of the time difference ultrasonic heat meter, can solve the problems of reducing the error consistency, inaccurate flow measurement, and generating backflow, etc., so as to avoid multiple meters, ensure accuracy, The effect of improving consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

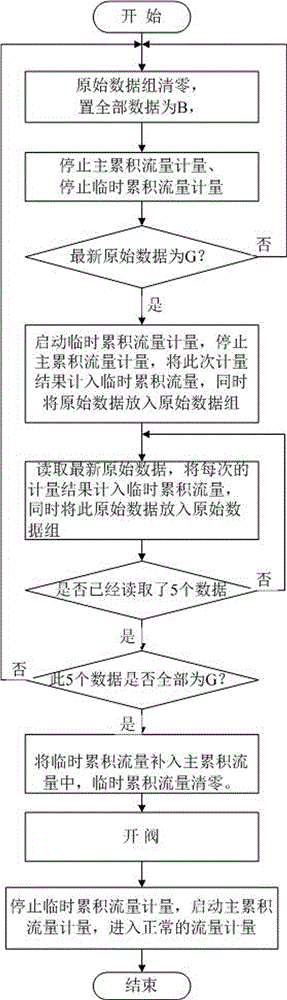

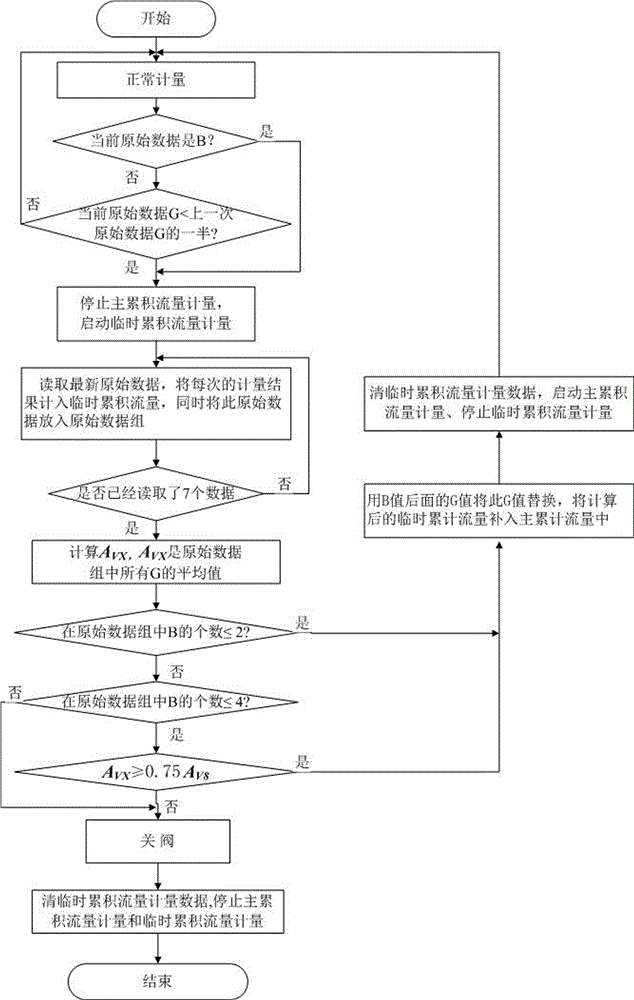

Examples

Embodiment Construction

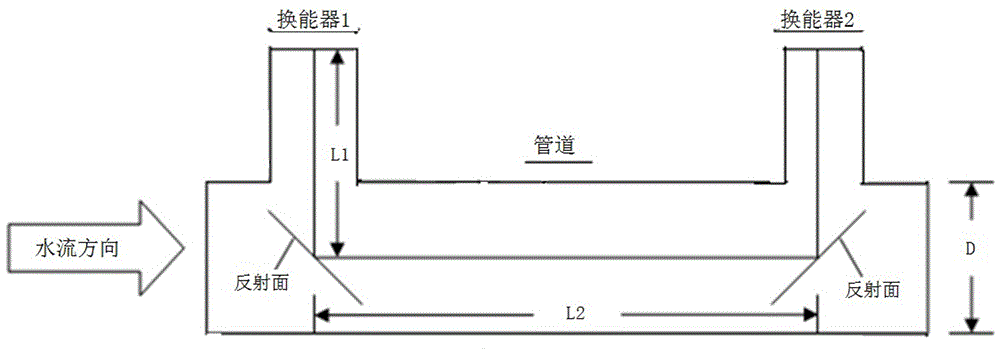

[0023] Such as figure 1 As shown, the present invention is mainly suitable for the flow measurement of the transit-time ultrasonic heat meter: a pair of ultrasonic transducers are used to send and receive ultrasonic waves alternately (or at the same time), and the fluid is indirectly measured by observing the time difference of the forward and reverse flow of the ultrasonic waves in the medium The flow rate, and then calculate the flow rate by the flow rate.

[0024] The transit-time flow measurement method first obtains the relevant time data according to the following formula.

[0025]

[0026]

[0027]

[0028] In the formula, L 1 is the propagation length of the sound wave between two reflecting surfaces in the liquid; L 2 is the propagation length of the sound wave in the liquid between the reflecting surface and the transducer; D is the inner diameter of the pipe; C is the speed of the sound wave propagating in the liquid at rest; V is the average flow velocit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com