Online magnetron fault detecting method

A detection method and magnetron technology, applied in the detection field, can solve problems such as low accuracy, low precision, and increased cost, and achieve the effects of not being easy to misjudgment, high detection accuracy, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

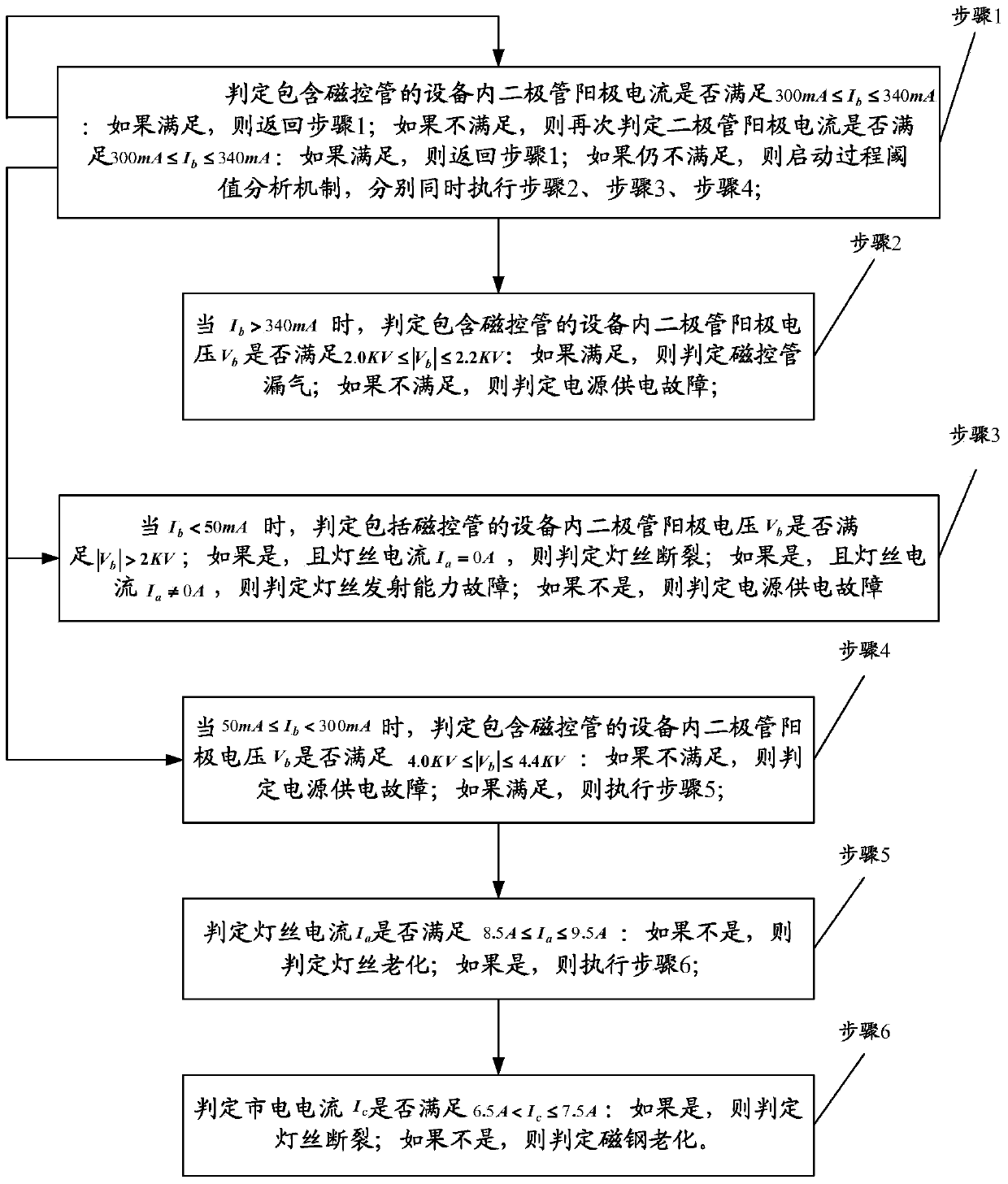

[0017] figure 1 It is a flow chart of the magnetron fault online detection method of the present invention. Such as figure 1 As shown, the magnetron fault online detection method described in the present invention, for the magnetron of 1 kilowatt output power, it comprises the following steps:

[0018] Step 1. Determine the diode anode current I in the device containing the magnetron b Whether meet 300mA≤I b ≤340mA: If satisfied, return to step 1; if not satisfied, judge the diode anode current I again b Whether meet 300mA≤I b ≤340mA: If it is satisfied, return to step 1; if it is still not satisfied, start the process threshold analysis mechanism, and perform steps 2, 3, and 4 at the same time.

[0019] Step 2, when I b When >340m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com