Flooring having PLA layer

A floor and surface technology, applied in the direction of floor, thin material processing, building materials, etc., can solve the problems of difficult to present manual effect, poor water and heat resistance, difficult to ensure productivity, etc., to ensure environmental friendliness and ensure surface performance. , the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Preferred embodiments of the present invention will be explained in detail with reference to the accompanying drawings.

[0025] In the drawings, even if the same components are shown in different drawings, their reference numerals are the same.

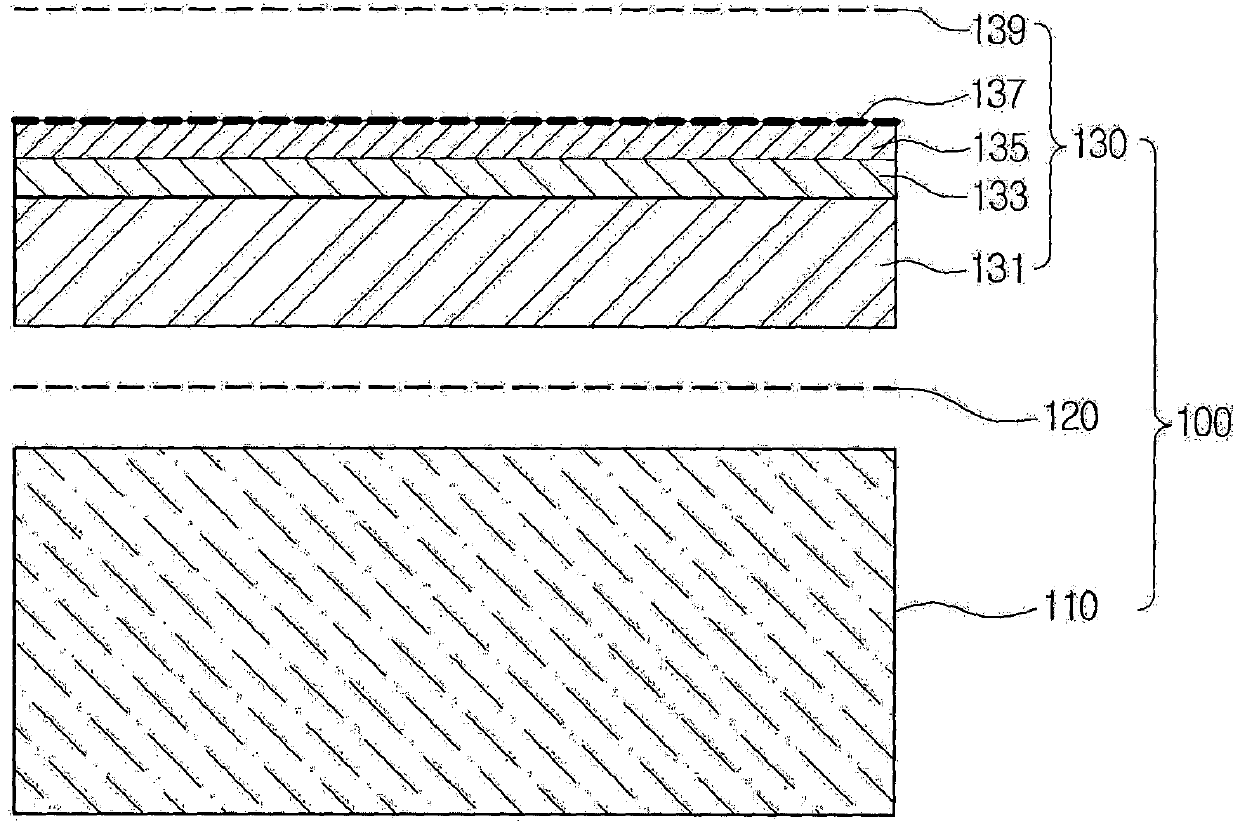

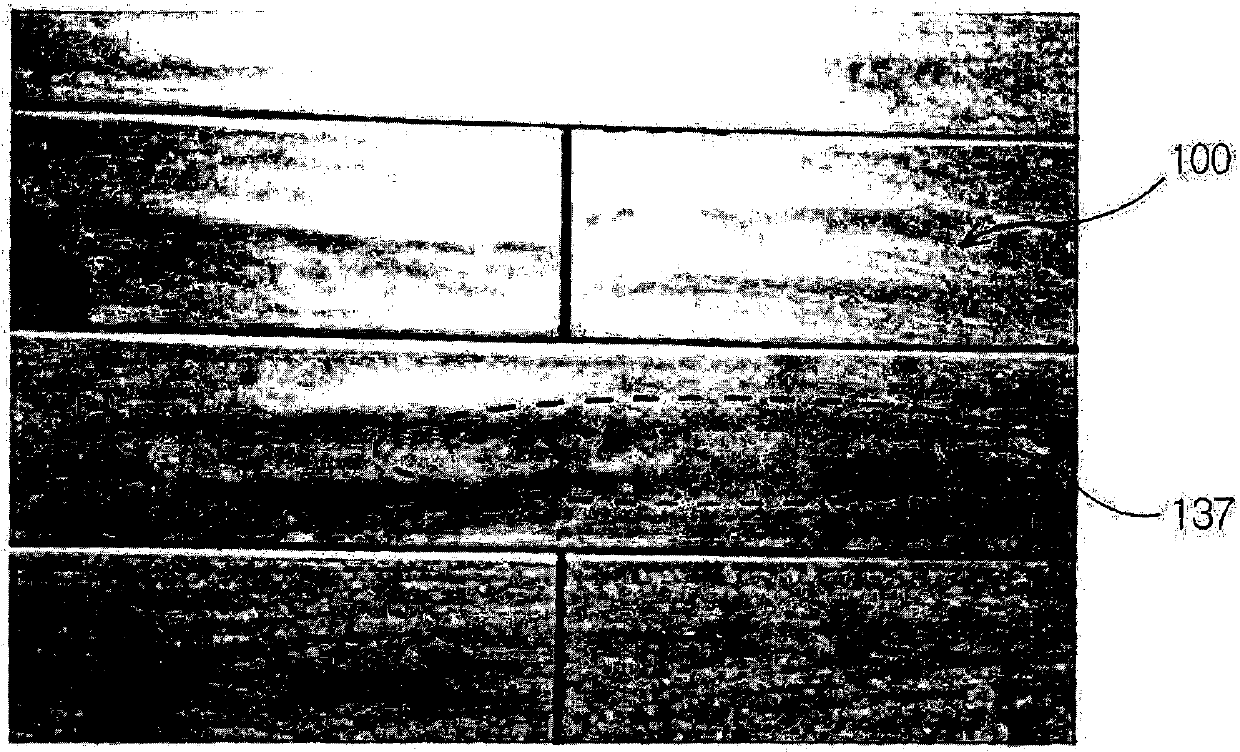

[0026] figure 1 is a cross-sectional view of the floor of the present invention, figure 2 It is a photograph showing the bending pattern of the floor of the present invention.

[0027] refer to figure 1 and figure 2 , the floor 100 of the preferred embodiment of the present invention is laid on the ground of a building, and includes: a base layer 110; At least one of the reinforcing layer 131, the printing layer 133, and the transparent layer 135 is made of PLA (polylactic acid) resin. The curved pattern 137 is formed on the surface layer 130 .

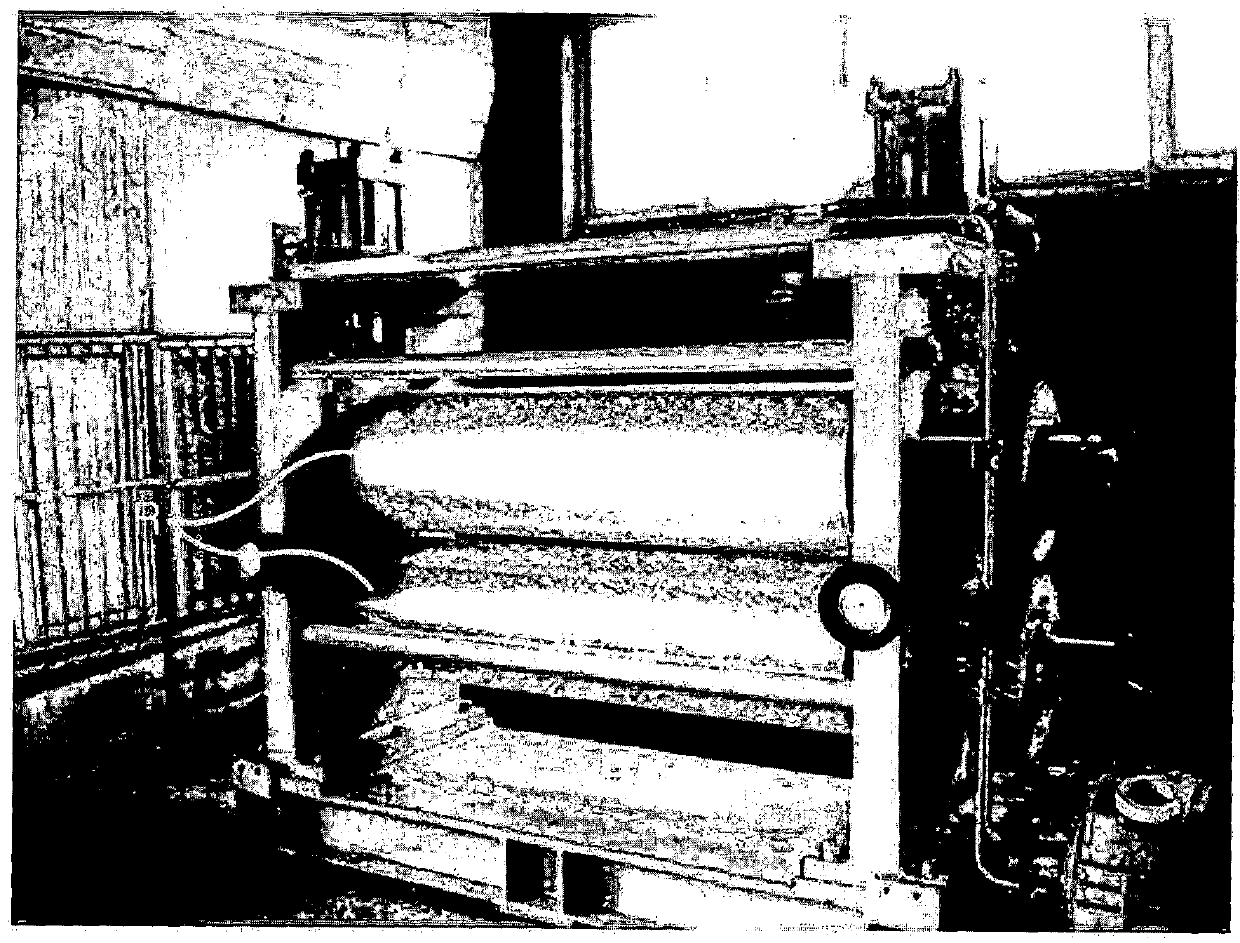

[0028] Here, it is preferable that the curved pattern 137 is formed by pressing the skin 130 after passing the skin 130 through a pair of rotating embossing rolls (R). (see ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com