Hand glue applicator

A gluing machine and gluing technology, which is used in container manufacturing machinery, paper/cardboard containers, box making operations, etc., can solve the problems of low production efficiency and uneven distribution of glue in hand-held gluing, and avoid waste of glue water resources. , The effect of stable spacing and stable glue quantity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

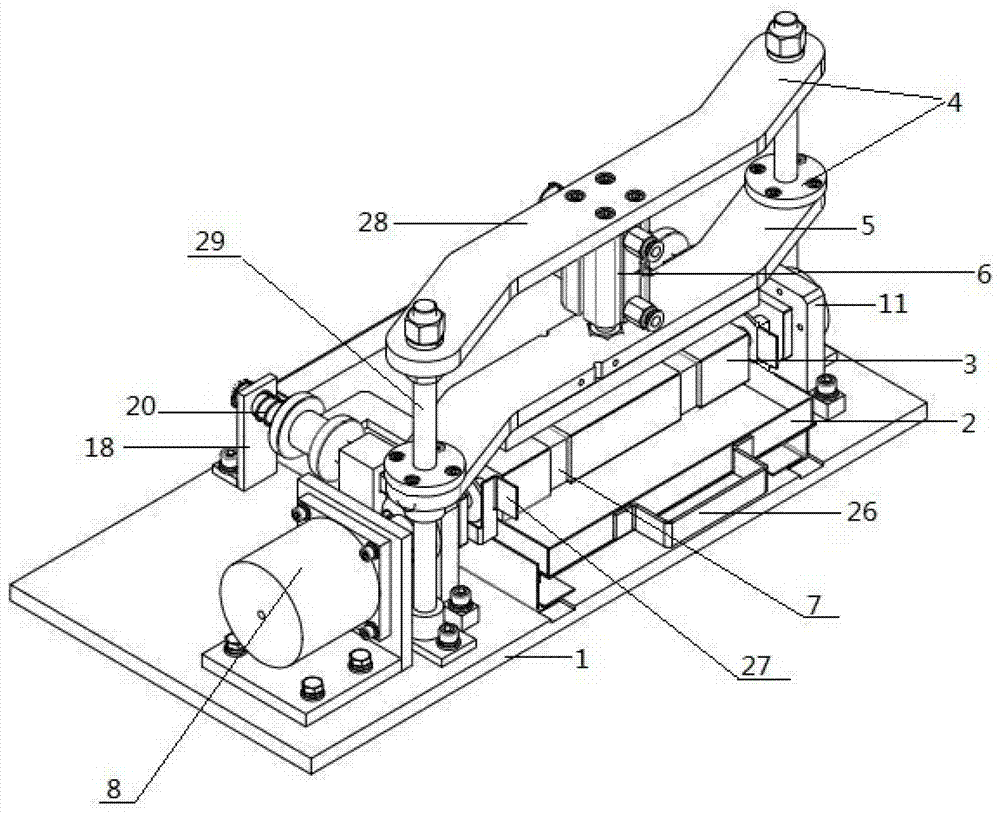

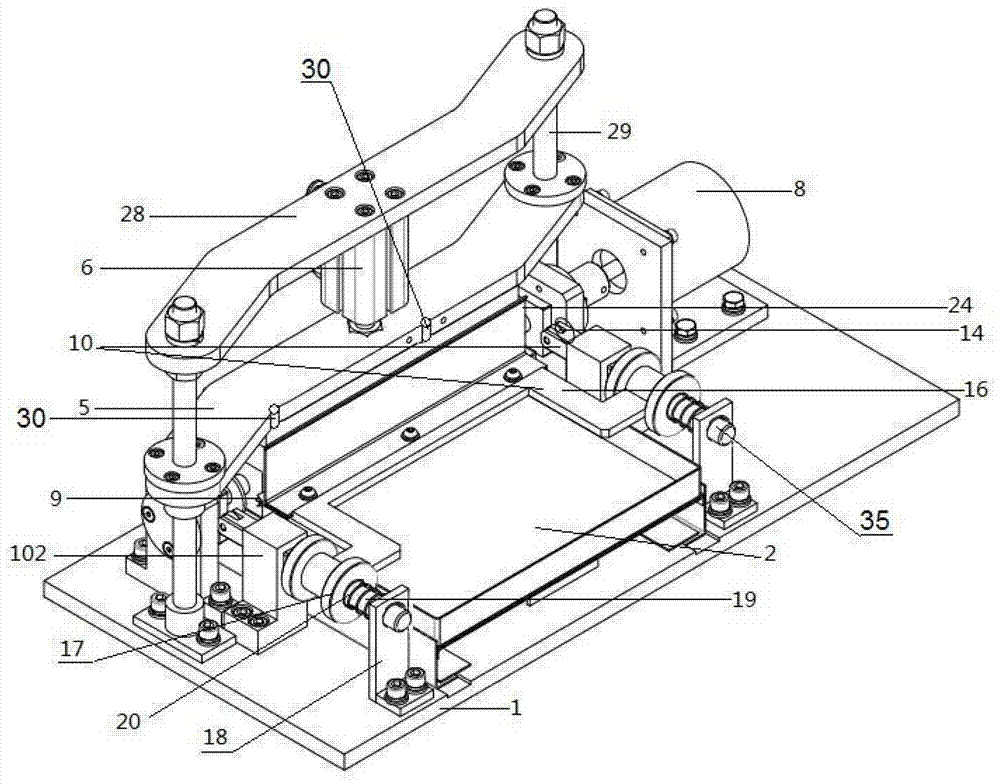

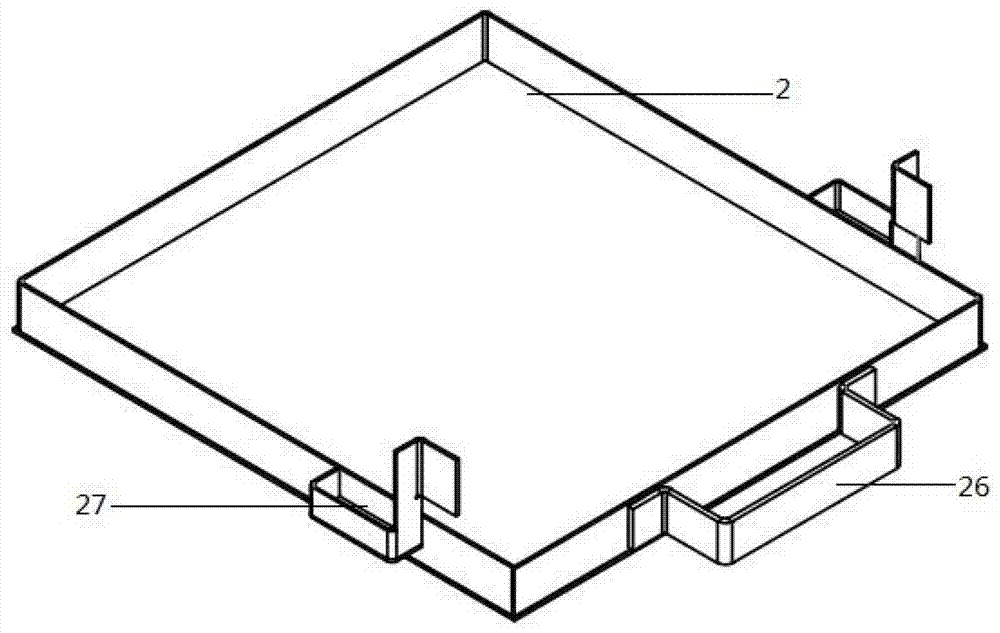

[0051] Such as figure 1 The embodiment shown is a kind of hand glue applicator, comprises base plate 1, the glue box 2 that is located at the upper end opening of base plate, motor 8, horizontal gluing structure 3 and frame 4; One end of horizontal gluing structure and motor The rotating shaft is connected, the horizontal gluing structure is columnar, the cross section of the horizontal gluing structure is polygonal, and the outer surface of the horizontal gluing structure is provided with two annular grooves 7 for matching with the handle; There is a pressing plate 5 for cooperating with the upper surface of the horizontal gluing structure and a power device 6 that can drive the pressing plate to move up and down; the lower part of the horizontal gluing structure is located in the glue box. A fixing seat 11 is arranged on the bottom plate.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com